More Progress

While waiting to wire the outlets, I took advantage of the unseasonably warm weather and painted the floor using the Rustoleum Epoxy paint. It worked as advertised. If I had it to do over again I would skip the colored flecks.

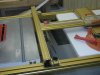

I have also edge-banded the flip-top cart, added castors and built the top. I still have to attach it to the carcass, but I didn't want to take the PC router out of table right now.

I built a quick detachable pegboard unit in about 30 minutes, pics to follow. Attached are shots show the shop with a lot of stuff moved in. Things will change as I build permanent cabinets. I think I am going to need storage shelves up high for infrequrntly used items.

Have a happy and safe holiday and new year.

Doug

While waiting to wire the outlets, I took advantage of the unseasonably warm weather and painted the floor using the Rustoleum Epoxy paint. It worked as advertised. If I had it to do over again I would skip the colored flecks.

I have also edge-banded the flip-top cart, added castors and built the top. I still have to attach it to the carcass, but I didn't want to take the PC router out of table right now.

I built a quick detachable pegboard unit in about 30 minutes, pics to follow. Attached are shots show the shop with a lot of stuff moved in. Things will change as I build permanent cabinets. I think I am going to need storage shelves up high for infrequrntly used items.

Have a happy and safe holiday and new year.

Doug