I am not thinking of mass producing carvings; I am thinking about carving designs on scrap and transferring the roughed out carving to an instrument and then doing the detail by hand. Anyway, I came across this carver's pages on his pantograph:

http://www.dust-n-shavings.com/pantograph/howItWorks.htm

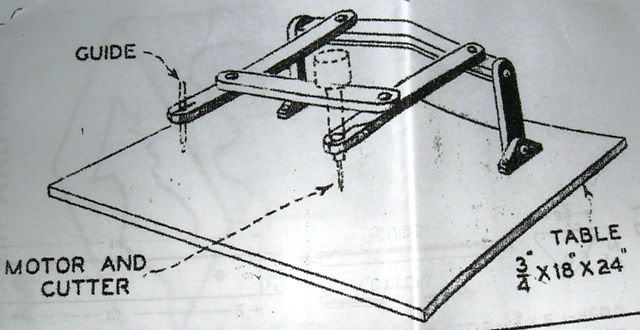

and then I purchased a plan on eBay for this one:

That's the listing picture. I think it purposefully obscures a lot of detail because there isn't much to it, but I figured it was worth $8 to have some instructions and dimensions to work with. I am pretty sure it is just a reprint of an old article, but I can't find it anywhere and the seller claims to hold the copyright. There was also a picture of the guy with the finished bust and it looks pretty good.

Anyway, I am curious if others here have any experience with a pantograph style. What I have gleaned from searching and reading is that are not quite as acurate as the CopyCarver wheel and rail type, but are fine for rough outs, aren't quite as sturdy and may need repair/replacement more often, but take up significantly less space and are easier to build. Those are big postives for me; all I want is roughing out and only occasionally.

http://www.dust-n-shavings.com/pantograph/howItWorks.htm

and then I purchased a plan on eBay for this one:

That's the listing picture. I think it purposefully obscures a lot of detail because there isn't much to it, but I figured it was worth $8 to have some instructions and dimensions to work with. I am pretty sure it is just a reprint of an old article, but I can't find it anywhere and the seller claims to hold the copyright. There was also a picture of the guy with the finished bust and it looks pretty good.

Anyway, I am curious if others here have any experience with a pantograph style. What I have gleaned from searching and reading is that are not quite as acurate as the CopyCarver wheel and rail type, but are fine for rough outs, aren't quite as sturdy and may need repair/replacement more often, but take up significantly less space and are easier to build. Those are big postives for me; all I want is roughing out and only occasionally.