Yeah, I know; it looks like I am posting in the wrong section. This is exactly what lathes were made for. But I don't have one. I may make a small one or get one of those tiny hobby ones for just this purpose, but for now, I am thinking about how to carve and/or sand to do it. Here's the application:

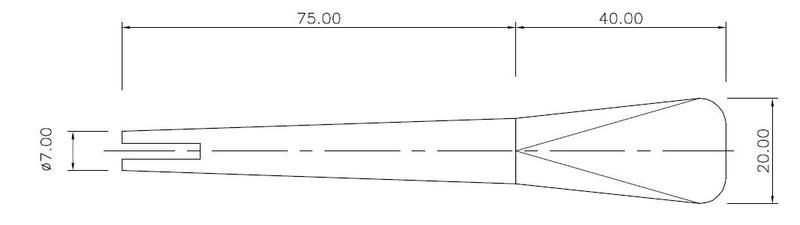

That is not the one I am building; it will be natural finish. Anyway, I chose that pic because it shows the pegs pretty clearly. I have cut and roughed 3 pegs out of pear wood. Right now they look like small tan carrots. I will grind a reamer from an old pair of scissors to do the taper inside of the peg holes. I need the peg taper to match pretty closely or it won't hold a tuning well. I can make a peg shaper, but that is just for final fitting. Basically, you use the reamer in a block of wood and then cut it open to expose part of the hole and make what looks like a big pencil sharpener. But the peg has to be pretty close before that works.

Ideas?

That is not the one I am building; it will be natural finish. Anyway, I chose that pic because it shows the pegs pretty clearly. I have cut and roughed 3 pegs out of pear wood. Right now they look like small tan carrots. I will grind a reamer from an old pair of scissors to do the taper inside of the peg holes. I need the peg taper to match pretty closely or it won't hold a tuning well. I can make a peg shaper, but that is just for final fitting. Basically, you use the reamer in a block of wood and then cut it open to expose part of the hole and make what looks like a big pencil sharpener. But the peg has to be pretty close before that works.

Ideas?