You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

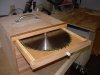

Blade storage box w/ pics (WIP)

- Status

- Not open for further replies.

I had been thinking about this problem for a while. I had not come up with anything this nice however.

I might have to borrow from your idea.

I might have to borrow from your idea.

I built the box shown here from sketched plans in the Tips section of some WW magazine. But I can't remember which magazine!

It's made from some plywood, pine and hardwood scrap pieces. Pretty simple to built. It has 10 drawers or trays to hold blades. (In this case all ten inch blades.)

Keeps the blades separated and isolated, so you don't skin up you hands on the teeth of adjacent blades.

It's made from some plywood, pine and hardwood scrap pieces. Pretty simple to built. It has 10 drawers or trays to hold blades. (In this case all ten inch blades.)

Keeps the blades separated and isolated, so you don't skin up you hands on the teeth of adjacent blades.

Attachments

Walt,

That chest of (blade) drawers really does look nice... and it answers the challenge of different size blades. you could even store spare jointer blades in a drawer.

Ray

That chest of (blade) drawers really does look nice... and it answers the challenge of different size blades. you could even store spare jointer blades in a drawer.

Ray

Both solutions look good! They both raise issues I want to incorporate into the cabinet I have been thinking about building under my TS extension table to hold blades, jigs, push sticks, etc. etc.

I am thinking of making a blade drawer similar to Jay's box, with the blades standing on edge, so I can see all the blades at one time, but build it so it that tilts out.

Also, I am thinking about putting a radius on the tops of the dividers that is slightly larger than the radius of the blades so the tips are slightly below the tops of the dividers, are protected, and my knuckles are protected . I would probably need two sections- one for my 10" TS and CMS blades and another for my 8" dado blade and chippers.

. I would probably need two sections- one for my 10" TS and CMS blades and another for my 8" dado blade and chippers.

Since the blade tips would be below the dividers, I would bevel an area of the that angles away from the blade, on the inside top edge of both adjoining dividers so I could grab a blade and remove it. These beveled areas would need to be in different positions on the dividers, blade to blade, otherwise the bevels would cut into each other and you would expose the teeth of the adjacent blade near your knuckles.

This method would allow me to see a section of the blade/teeth to make my blade selection and allow me to put my fingers in to grab and pull out a blade without my knuckles hitting any other blades. Clear as mud? I wish I was good at Autocad or Sketchup!!!

I am thinking of making a blade drawer similar to Jay's box, with the blades standing on edge, so I can see all the blades at one time, but build it so it that tilts out.

Also, I am thinking about putting a radius on the tops of the dividers that is slightly larger than the radius of the blades so the tips are slightly below the tops of the dividers, are protected, and my knuckles are protected

Since the blade tips would be below the dividers, I would bevel an area of the that angles away from the blade, on the inside top edge of both adjoining dividers so I could grab a blade and remove it. These beveled areas would need to be in different positions on the dividers, blade to blade, otherwise the bevels would cut into each other and you would expose the teeth of the adjacent blade near your knuckles.

This method would allow me to see a section of the blade/teeth to make my blade selection and allow me to put my fingers in to grab and pull out a blade without my knuckles hitting any other blades. Clear as mud? I wish I was good at Autocad or Sketchup!!!

J,

You can throw that box my way if you want to throw it out :rolf:

Man. that's way better than I could build .

Couple of hours ? It would take me a couple of days to even figure out how to cut the pieces :lol:

I like it !

Alan had me lost by the 5th sentence of his post :drunken_s

You can throw that box my way if you want to throw it out :rolf:

Man. that's way better than I could build .

Couple of hours ? It would take me a couple of days to even figure out how to cut the pieces :lol:

I like it !

Alan had me lost by the 5th sentence of his post :drunken_s

Jay,

Don't do that! Your setup is OK. Functional and straight forward. The case I built wasn't my idea!!!!! But, I did like the isolation of the blades from each other though.

By the way, I store my blade case on a shelf in a roll-around cabinet in which I store other TS accessories like dado set, tenoning jig, wrenches, throat plates, etc. It is too heavy with 7 or 8 blades in it to lug around the shop very much. The roll-around also acts as an additional outfeed support occasionally, so it's generally close to the TS.

Don't do that! Your setup is OK. Functional and straight forward. The case I built wasn't my idea!!!!! But, I did like the isolation of the blades from each other though.

By the way, I store my blade case on a shelf in a roll-around cabinet in which I store other TS accessories like dado set, tenoning jig, wrenches, throat plates, etc. It is too heavy with 7 or 8 blades in it to lug around the shop very much. The roll-around also acts as an additional outfeed support occasionally, so it's generally close to the TS.

- Status

- Not open for further replies.

LATEST FOR SALE LISTINGS

-

-

-

SOLD -- $75: Gast moa v113 Vacuum Pump Veneer, 60" bag and board

- Started by peterdnight

- Replies: 1

-

GONE: Gladiator 5 cleats, 10 hangers, Paper Towel and Shelf

- Started by peterdnight

- Replies: 3

-

SOLD -- $100 Makita mac700 portable air + grex pin nailer + 2 others + 50' hose

- Started by peterdnight

- Replies: 1