Thanks to Mitch (Amish Warlord), his truck, his back (sorry!), and Tony's Genie lift I got my new (to me) Delta 28-475X bandsaw home on saturday. I spent the rest of the weekend trying to get a 3/4" x 3AS-S timberwolf blade set up on it for cutting a few turning blanks. No matter where I put the blade on the wheels, it climbs its way to the edge and stops once the teeth are off of the tire and over the wheel taper. I took the riser loose (after a couple of trips to Harbor Freight and Sears to get a 1 1/8" wrench and later a 1 1/4" wrench when I figured out that the nut on the 3/4" bolt was a heavy duty nut... :BangHead: ) and made sure the wheels were aligned and coplaner. I played with the tracking adjustment which works by using a set screw to adjust the angle of the upper wheel. No matter what I do, the blade works its way to the edge of the wheel. I would let it run in its "happy place", but at the edge it hits the clip that hold the lower door closed and makes a horrible noise too! :confused_

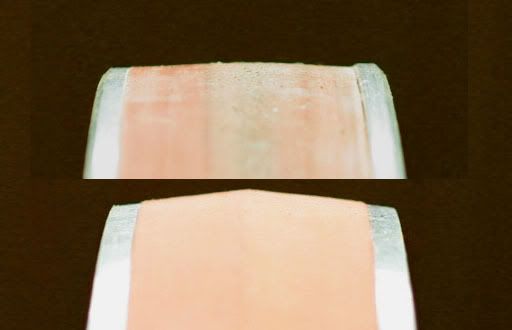

Does the alternate set tooth pattern of the blade pull the blade to the edge of the wheel? Is there a way to try and center the blade? Should I reduce the blade tension? Any help would be appreciated! Here is a pic of the blade in its "happy place" (sorry for the cell phone pic!!!!)

Does the alternate set tooth pattern of the blade pull the blade to the edge of the wheel? Is there a way to try and center the blade? Should I reduce the blade tension? Any help would be appreciated! Here is a pic of the blade in its "happy place" (sorry for the cell phone pic!!!!)