You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1782 Stockburger Farmhouse Renovation

- Thread starter Reference Handiwork

- Start date

-

- Tags

- log home

For anybody following along, here are a few photos and updates. Managing subcontractors has been the most difficult part of this project. That said, we have some very detail oriented help and are making progress. We may run out of money before we finish, but it looks like we'll be able to get it water tight before then.

I'm currently remaking the window casings for two sides of the house. The original ones are badly warped and will not meet the siding correctly now that we have added OSB sheathing to these walls. Of course there is no dimensional lumber that is the right size, so I'm making them from treated 2x6s. It works pretty well, but is a time consuming process. This is a dry fit. After I finished it I primed all sides before installing with deck screws.

The winow unit in the living room is fully functional. All new glass. Primed with oil primer, then two coats of Sherman Williams exterior paint. The top sash is now fixed in with caulk and hidden trim screws. The bottom sash is fully functional and rides up and down on a galvanized track. They work better than new.

Our carpenter built this great side porch for us. The main posts are 4x6s. We'll stain and seal it....someday. This will be the primary entrance that my wife and I use to enter the home. The door for this spot has been stripped, sanded, primed, painted, and re-glazed with tempered glass. I can't wait to get it installed. The hip roof here is new, too. I used self-sealing underlayment and typical 3 tab shingles.

There used to be a doorway in place of that transom window, but it was about 5ft tall, in a wall that was completely rotten, and went to a porch that no longer exists and would extend to what is now the neighbor's property. It's great knowing that we went from a wall with no sheathing, to having 5/16 OSB and house wrap. It'll keep the house a lot drier, quieter, and warmer.

This wall was completely composed of rotten logs. We reframed it with 2/8s, and it still isn't quite thick enough. We'll fur it out before drywall.

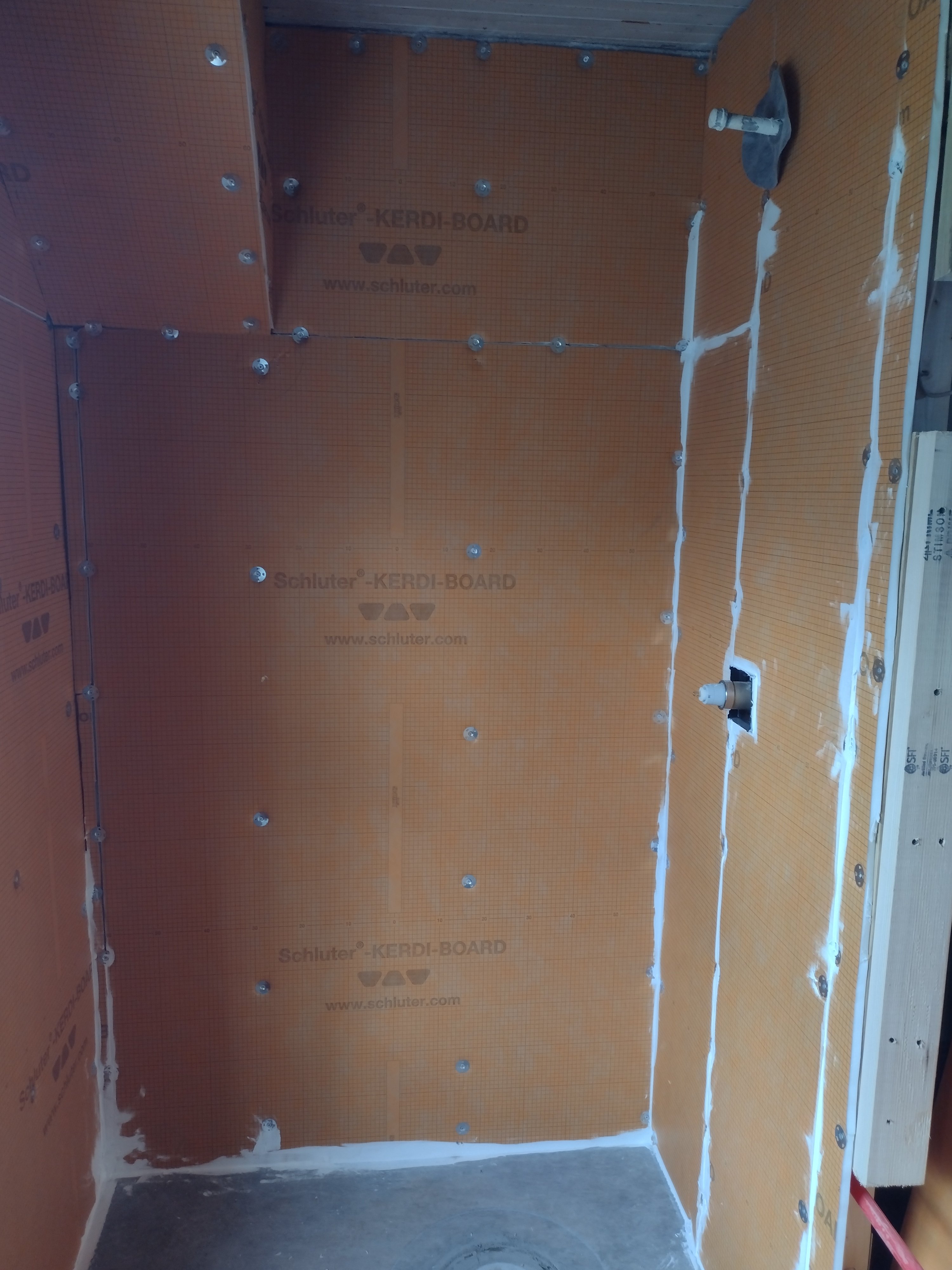

Here is one of the three tiled showers. We have a great tile guy. This is my first experience with kerdi board. It's fine, but...

Here we are evaluating the logs on one of the two walls where we removed the siding to add OSB sheathing. There was no sheathing here before, so water intrusion had created a lot of rot in the 1782 logs. We replaced completely rotten logs with 2x8s and 2x10s fashioned into hollow beams, sort of like miniature load bearing walls, which is what they really are.

Here's an example of one of the replaced sections. The top part is where the log home turns into conventional framing. We reinforced all of the old 2x4s with new lumber.

That's all for now. We're hoping to get two of the exterior walls sided and painted in the coming month or so. We're using 8" beveled pine siding. We're priming it on both sides prior to installing it. Wish us luck.

I'm currently remaking the window casings for two sides of the house. The original ones are badly warped and will not meet the siding correctly now that we have added OSB sheathing to these walls. Of course there is no dimensional lumber that is the right size, so I'm making them from treated 2x6s. It works pretty well, but is a time consuming process. This is a dry fit. After I finished it I primed all sides before installing with deck screws.

The winow unit in the living room is fully functional. All new glass. Primed with oil primer, then two coats of Sherman Williams exterior paint. The top sash is now fixed in with caulk and hidden trim screws. The bottom sash is fully functional and rides up and down on a galvanized track. They work better than new.

Our carpenter built this great side porch for us. The main posts are 4x6s. We'll stain and seal it....someday. This will be the primary entrance that my wife and I use to enter the home. The door for this spot has been stripped, sanded, primed, painted, and re-glazed with tempered glass. I can't wait to get it installed. The hip roof here is new, too. I used self-sealing underlayment and typical 3 tab shingles.

There used to be a doorway in place of that transom window, but it was about 5ft tall, in a wall that was completely rotten, and went to a porch that no longer exists and would extend to what is now the neighbor's property. It's great knowing that we went from a wall with no sheathing, to having 5/16 OSB and house wrap. It'll keep the house a lot drier, quieter, and warmer.

This wall was completely composed of rotten logs. We reframed it with 2/8s, and it still isn't quite thick enough. We'll fur it out before drywall.

Here is one of the three tiled showers. We have a great tile guy. This is my first experience with kerdi board. It's fine, but...

Here we are evaluating the logs on one of the two walls where we removed the siding to add OSB sheathing. There was no sheathing here before, so water intrusion had created a lot of rot in the 1782 logs. We replaced completely rotten logs with 2x8s and 2x10s fashioned into hollow beams, sort of like miniature load bearing walls, which is what they really are.

Here's an example of one of the replaced sections. The top part is where the log home turns into conventional framing. We reinforced all of the old 2x4s with new lumber.

That's all for now. We're hoping to get two of the exterior walls sided and painted in the coming month or so. We're using 8" beveled pine siding. We're priming it on both sides prior to installing it. Wish us luck.

Last edited:

Really cool project, I am sure you have dealt with a lot of challenges both physically and emotionally. You have done a great job based on the pictures and story line.

Keep at it.

Keep at it.

A quick progress update:

Drywall is going in over any new or rebuilt wall. It really helps to define the spaces.

This will be our laundry room. I'm beyond pleased with how it's coming together.

This is our primary bathroom. The wallboard really brings it all together. Our tiling specialist is making great progress putting down our 2" marble hex tiles.

On the back of the house we are beginning to put up the beveled pine siding. To help mitigate rot and movement we have back primed everything and are priming the cut ends, as well as pre-caulking all joints. It's Slow going, but it's going. The window casings are all new on the outside, except for the sills.

Here's a look at my next window sash adventure.

Two sashes up on the operating table:

We've recently passed rough in inspection for HVAC, electrical, and plumbing. Now it's a big push to try and get it all sealed up so that we can begin installing fixtures. I'll be on site for two complete weeks at the end of May and beginning of April and am hoping that we can get the whole thing primed and painted. We'll see how it goes.

Drywall is going in over any new or rebuilt wall. It really helps to define the spaces.

This will be our laundry room. I'm beyond pleased with how it's coming together.

This is our primary bathroom. The wallboard really brings it all together. Our tiling specialist is making great progress putting down our 2" marble hex tiles.

On the back of the house we are beginning to put up the beveled pine siding. To help mitigate rot and movement we have back primed everything and are priming the cut ends, as well as pre-caulking all joints. It's Slow going, but it's going. The window casings are all new on the outside, except for the sills.

Here's a look at my next window sash adventure.

Two sashes up on the operating table:

We've recently passed rough in inspection for HVAC, electrical, and plumbing. Now it's a big push to try and get it all sealed up so that we can begin installing fixtures. I'll be on site for two complete weeks at the end of May and beginning of April and am hoping that we can get the whole thing primed and painted. We'll see how it goes.

Finally got another sash window installed recently. It runs up and down on galvanized metal tracks. The whole wall is pretty discombobulated, but the window functions.

I had a load bearing beam that originally sat on the rubble stone foundation and was rotten on the inside. The outside of the beam, though, was fairly solid. There was no way to access it without either removing the foundation wall or the log wall it supports. So, reluctancly, I cleaned it out as best as I could and filled it with concrete and rebar, making it into a pseudo-reinforced-concrete beam.

Here's something fun. Our tile guy is making fantastic progress our showers. I love this Spanish made star tile that we're using for the pan of one them.

That's all for now

I had a load bearing beam that originally sat on the rubble stone foundation and was rotten on the inside. The outside of the beam, though, was fairly solid. There was no way to access it without either removing the foundation wall or the log wall it supports. So, reluctancly, I cleaned it out as best as I could and filled it with concrete and rebar, making it into a pseudo-reinforced-concrete beam.

Here's something fun. Our tile guy is making fantastic progress our showers. I love this Spanish made star tile that we're using for the pan of one them.

That's all for now

I discovered years ago that sealing up clapboard siding at the bottom underside joint I’d not a good idea as the clapboards need to breath. Caulking up the surface is desirable but the paint will peel quickly if too tight. Used to be, one could buy little plastic wedges to prop open the joint crack but I haven’t worked with that siding in many many yrs.

If your windows use weights and pulleys to open and shut, I have 30 or 40 weights you can have for free. I used to do a lot of window glazing, house painting etc.

Thanks Robert! I also have a bunch of extras. In this case. We're going from double hung to single hung, so I have double what I really need. They're brilliant... when they work.

I discovered years ago that sealing up clapboard siding at the bottom underside joint I’d not a good idea as the clapboards need to breath. Caulking up the surface is desirable but the paint will peel quickly if too tight. Used to be, one could buy little plastic wedges to prop open the joint crack but I haven’t worked with that siding in many many yrs.

Thanks for the great advice. That siding was difficult to source, and expensive. We're currently caulking the vertical joints, but leaving the undersides open. In some places we're leaving a bit of a gap at the ends, but I'm anticipating more shrinking than expansion, so they're a little tight in some places. We'll see if I come to regret that.

Finished the siding on the back! We have scaffolding for the middle top section.

I threw together a little door of treated lumber so we can use this crawl space to store stuff.

I'll be here nearly every day over the coming two weeks. We're trucking right along.

I threw together a little door of treated lumber so we can use this crawl space to store stuff.

I'll be here nearly every day over the coming two weeks. We're trucking right along.

A few more photos of recent progress.

The plaster in this section of wall was too far gone to keep, so we knocked it out and will drywall. I also now have the chance to insulate (with an air gap, because this is one of the few places without sheathing). Check out this top log. It's hand hewn and about 9 1/4" X 11 1/2". Go pick that up at Lowes!

In what will be our bedroom we discovered some small bits of wallpaper hiding in the walls. What do you think this is all about?

This wall of our bedroom is against the front porch, where our guesthouse visitors will enter. To help keep down the noise I insulated it and then added acoustic board before drywall.

The tile in our primary bathroom is done and our tile guy did a great job with some of the tricky cuts!

We finally stained and sealed our side porch, which will be our main entrance to the home.

I went for an unconventional trim to the entrance door. This is the inside of the door. I used oak base shoe, finished with wipe on poly, to frame in the tempered replacement glass. I'm happy with how it's turned out.

We have a new site supervisor who doesn't do a damn thing. Don't hire her, she's very lazy:

That's all for now. Most nights I'm working on windows right now. Windows for days and days.

The plaster in this section of wall was too far gone to keep, so we knocked it out and will drywall. I also now have the chance to insulate (with an air gap, because this is one of the few places without sheathing). Check out this top log. It's hand hewn and about 9 1/4" X 11 1/2". Go pick that up at Lowes!

In what will be our bedroom we discovered some small bits of wallpaper hiding in the walls. What do you think this is all about?

This wall of our bedroom is against the front porch, where our guesthouse visitors will enter. To help keep down the noise I insulated it and then added acoustic board before drywall.

The tile in our primary bathroom is done and our tile guy did a great job with some of the tricky cuts!

We finally stained and sealed our side porch, which will be our main entrance to the home.

I went for an unconventional trim to the entrance door. This is the inside of the door. I used oak base shoe, finished with wipe on poly, to frame in the tempered replacement glass. I'm happy with how it's turned out.

We have a new site supervisor who doesn't do a damn thing. Don't hire her, she's very lazy:

That's all for now. Most nights I'm working on windows right now. Windows for days and days.

Maybe they put them up to see how they would look on a wall like we do with paint samples today. If you put them on the sheathing you don't have the hassle of taking it off the plaster.In what will be our bedroom we discovered some small bits of wallpaper hiding in the walls. What do you think this is all about?

View attachment 230498

That was one thought that I had, too. Seems likely.Maybe they put them up to see how they would look on a wall like we do with paint samples today. If you put them on the sheathing you don't have the hassle of taking it off the plaster.