Any framers out there?

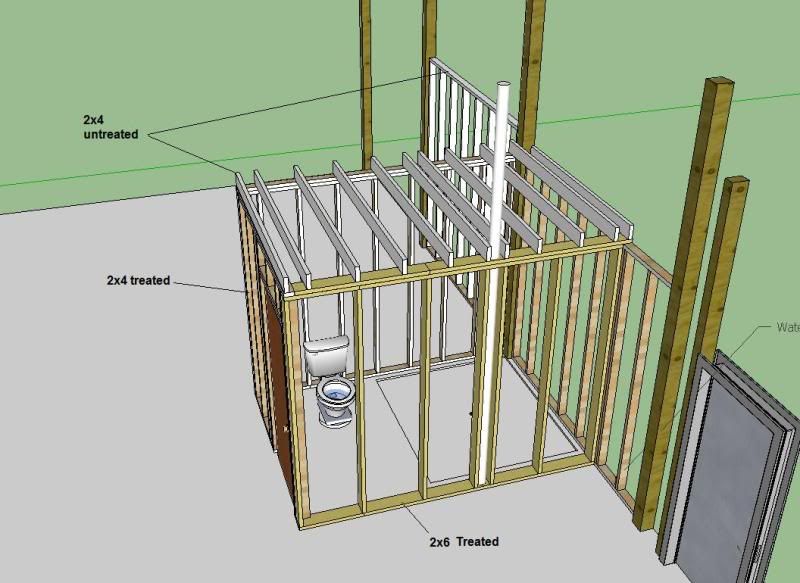

I need to put up walls for a bathroom in my shop. I can build the 4 walls, but is there a preferred or required layout for butting the walls together at the corners? 2 opposite walls inside the other 2 walls, or overlap each corner differently, or ??. :dontknow I know the top plates will overlap to lock in the corners.)

I know the top plates will overlap to lock in the corners.)

Also, the sewer (stack?) pipe is sticking up from the floor and should be inside one wall. What is the correct method to cut-out the plates for the pipe?

I need to put up walls for a bathroom in my shop. I can build the 4 walls, but is there a preferred or required layout for butting the walls together at the corners? 2 opposite walls inside the other 2 walls, or overlap each corner differently, or ??. :dontknow

Also, the sewer (stack?) pipe is sticking up from the floor and should be inside one wall. What is the correct method to cut-out the plates for the pipe?