You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cleaning up an old Disston D-8

- Thread starter PappiJoe

- Start date

I just cleaned they plate... Covered the etch and let it sit..... Small sanding block with 2000 grit and gently removed it. Repeat of necessary but don't over-sand.

2000 grit?

Wet dry sand paper comes in higher grits such as 800, 1000, 1200, 1500, and 2000. It's used in the automotive paint industry and furniture finishing as well. Klingspor carries it. I keep several sheets of this type of paper around just for when I want to sand something to a high polish with minimal material removable.

I have some around, just wanted to make sure it wasn't a typo. Sounds like it was not.Wet dry sand paper comes in higher grits such as 800, 1000, 1200, 1500, and 2000. It's used in the automotive paint industry and furniture finishing as well. Klingspor carries it. I keep several sheets of this type of paper around just for when I want to sand something to a high polish with minimal material removable.

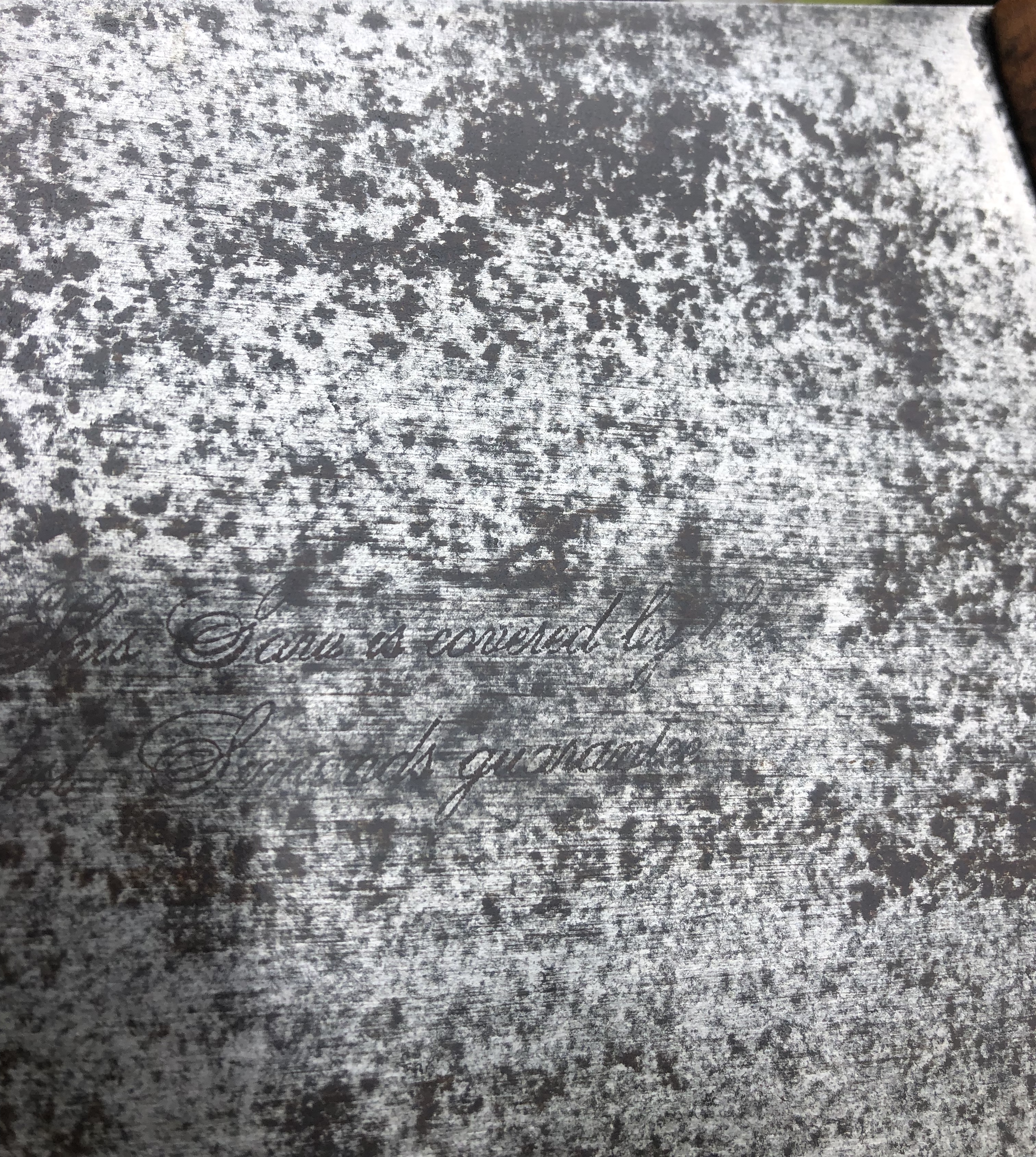

@Chris C I used the Perma Blue procedure on the latest saw I restored, a Simonds No. 371. The Perma Blue definitely helped bring out the etching. Now you can see that the saw was made in Fitchburg Mass Chicago Ill. “This Saw is covered by the broadest Simonds guarantee”.

I will do the etching on the D-8 next!

I will do the etching on the D-8 next!

Yep, and that Saw needs its back removed and reinstalled. I'd venture to say that this saw is not a canted saw. That's ok, it can be fixed and is one of the pieces of info I share in this up coming workshop.

Ok @Graywolf, I removed the back on the Disston backsaw and confirmed that it is 4" at the front & back. Then I reinstalled the back and located at an even distance from the saw teeth at the front and back. It seems that the back was misaligned for a while, you can still see the shadow of where the back was in the plate. Pics enclosed, BEFORE (small) and AFTER (Big).

Next step: sharpening...

Last edited:

It looks much better now. I do have to ask how straight the tooth line is now. I hope it's straight.Ok @Graywolf, I removed the back on the Disston backsaw and confirmed that it is 4" at the front & back. Then I reinstalled the back and located at an even distance from the saw teeth at the front and back. It seems that the back was misaligned for a while, you can still see the shadow of where the back was in the plate. Pics enclosed, BEFORE (small) and AFTER (Big).

Next step: sharpening...

View attachment 189436

View attachment 189441

One step at a time. I appreciate the "vote of confidence" @Graywolf .It looks much better now. I do have to ask how straight the tooth line is now. I hope it's straight.

Similar threads

- Replies

- 15

- Views

- 913

- Replies

- 3

- Views

- 289

LATEST FOR SALE LISTINGS

-

Powermatic 701 Mortiser, Like New, 3 new bits, 1 like new bit, 3 non-Powermatic bits, $550

- Started by frankc4113

- Replies: 0

-

For Sale Woodshop dust collection fittings, hose, separator, pipe

- Started by Ricardo

- Replies: 0

-

For Sale Wood Stabilizing Setup - Vac Chamber, Vac pump, & oven

- Started by beloitdavisja

- Replies: 0

-

For Sale Electrical supplies (Are you building a new shop?)

- Started by DSWalker

- Replies: 2

-