Her's the requested project

EDIT: Updates to 'progress' are below - completed pics is here - more commentary below (at the end) of this post.

Original message with my questions

:

Fireplace surround - there is brick in the field, and the opening where the fireplace itself USED TO be (no more) will be closed in with insulation and plywood. The project is meant to dress up the space and hide the now messy brick-to-wall transition.

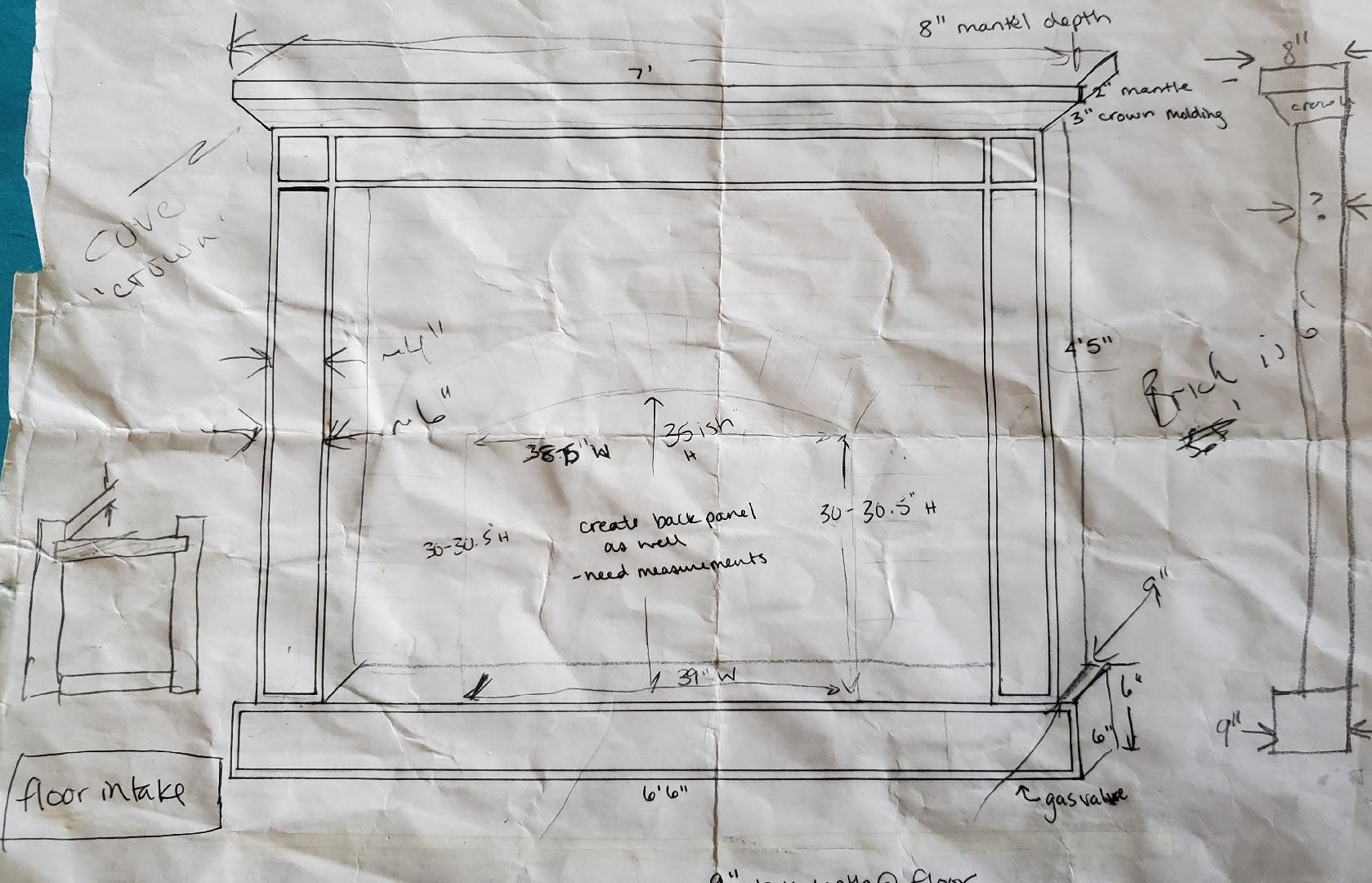

SO the project is 4 'boxes' and a mantle, with crown molding between them. Everything to be painted. Sketch is above.

The 4 boxes (base, 2 columns, and top) will have 4 sides of 4/4 poplar, an open back, and a dado-ed in flat front panel - inset 1/4 - 1/2" from the front face of boxes.

1. Which material would you use to make the front panel of the 4 major elements (boxes)? I have a full sheet of 1/2 birch plywood that may be more expensive than other choices, but I have it already and, while I could return it, I am inclined to use it. Any reason to substitute another type of plywood?

2. How deep would you groove the panel into the sides of the box; 3-16 - 1/4" is my inclination. More? Less?

3. How would you mount the mantle? I know that I can buy a kit with pins or rods or whatever, but I don't have to make this hidden; I can make brackets underneath the mantle that are hidden in the structure below. My inclination is a long 2x4 furring strip and a larger "corbel" on each end to support the front edge. Reasons not to do this? Cost of a kit seems unnecessary in this case.

With an open back, each of the boxes will have a 2x4 or 2x2 furring strip on the wall; each box to be screwed to the others, and attached to the furring strip.

Am I missing something to simplify this - or to make it better? Overall look is fixed by the 'client' - a family member. I will visit often and see it, so I don't want to regret my choices.

Thanks

EDIT: Updates to 'progress' are below - completed pics is here - more commentary below (at the end) of this post.

Original message with my questions

:

Fireplace surround - there is brick in the field, and the opening where the fireplace itself USED TO be (no more) will be closed in with insulation and plywood. The project is meant to dress up the space and hide the now messy brick-to-wall transition.

SO the project is 4 'boxes' and a mantle, with crown molding between them. Everything to be painted. Sketch is above.

The 4 boxes (base, 2 columns, and top) will have 4 sides of 4/4 poplar, an open back, and a dado-ed in flat front panel - inset 1/4 - 1/2" from the front face of boxes.

1. Which material would you use to make the front panel of the 4 major elements (boxes)? I have a full sheet of 1/2 birch plywood that may be more expensive than other choices, but I have it already and, while I could return it, I am inclined to use it. Any reason to substitute another type of plywood?

2. How deep would you groove the panel into the sides of the box; 3-16 - 1/4" is my inclination. More? Less?

3. How would you mount the mantle? I know that I can buy a kit with pins or rods or whatever, but I don't have to make this hidden; I can make brackets underneath the mantle that are hidden in the structure below. My inclination is a long 2x4 furring strip and a larger "corbel" on each end to support the front edge. Reasons not to do this? Cost of a kit seems unnecessary in this case.

With an open back, each of the boxes will have a 2x4 or 2x2 furring strip on the wall; each box to be screwed to the others, and attached to the furring strip.

Am I missing something to simplify this - or to make it better? Overall look is fixed by the 'client' - a family member. I will visit often and see it, so I don't want to regret my choices.

Thanks

Attachments

Last edited: