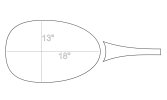

I am new to the cnc hobby and have made a few items such as edc/dump trays, phone chargers, fly fishing boxes, etc. I am now wanting to use it to create the mold for a landing net but am stumped as to where to begin with computer designing of an odd shaped elipse. Does fusion 360 have an option to find the circumference of odd shaped elipses (I couldn't figure it out on my own. Thanks and I appreciate any help/direction.

Peter

Peter