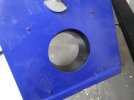

My idea of a paint brush in the lower compartment of the band saw to "strip" off any remaining dust had little effect. Not much more I can do for now. A little bit of foam in one corner, a couple strips of foil tape and no dust accumulates. I just get a little over the top in crosscuts.

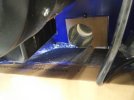

Reconnected my table saw to the ClearVue. I have one more trick to try to improve collection. That is to take their original output plate 4 inch flange and attach it to the door. Then a bit of flex host strapped to the trunion to focus the flow across the blade. I am going to contour the floor to better feed the duct. Like the band saw, the saw blade is quite a powerful fan and may not be easy to overpower.

Yea, going to have to keep the ClearVue. If I did not already have it, I still think a 3 or two two-motor Record Power systems are the way to go and have only one system. I am going to spend the money on further ambient filtering. I do need to fix the temporary 6 inch duct I put in before I moved the tools around and build a shroud over the Kapex.

Instead of running a duct to the drill press, I may just stuff one of my shop vacs under it with one of those ball-segment hoses and a small scoop. Quantity is so low, don't need to bother with a cyclone and instead of big bucks for the so called HEPA filter and bag, I am skeptical, I'll just exhaust through the wall to the outside.

Figured out the remote control for the vac. Now I want to do the same for the CV so I don't need to find where I left the remote and it does not like going through a wall anyway. Hardwire.

Reconnected my table saw to the ClearVue. I have one more trick to try to improve collection. That is to take their original output plate 4 inch flange and attach it to the door. Then a bit of flex host strapped to the trunion to focus the flow across the blade. I am going to contour the floor to better feed the duct. Like the band saw, the saw blade is quite a powerful fan and may not be easy to overpower.

Yea, going to have to keep the ClearVue. If I did not already have it, I still think a 3 or two two-motor Record Power systems are the way to go and have only one system. I am going to spend the money on further ambient filtering. I do need to fix the temporary 6 inch duct I put in before I moved the tools around and build a shroud over the Kapex.

Instead of running a duct to the drill press, I may just stuff one of my shop vacs under it with one of those ball-segment hoses and a small scoop. Quantity is so low, don't need to bother with a cyclone and instead of big bucks for the so called HEPA filter and bag, I am skeptical, I'll just exhaust through the wall to the outside.

Figured out the remote control for the vac. Now I want to do the same for the CV so I don't need to find where I left the remote and it does not like going through a wall anyway. Hardwire.