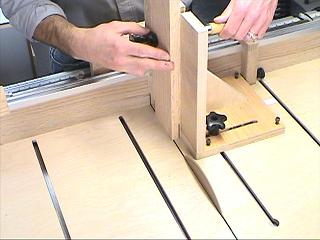

After switching saws (and fences), I needed a new tenon jig. The last one wasn't too great, anyway, so I took a queue from a recent Shop Notes and built one very similar to theirs (issue 101?). Having recently acquired a lifetime supply of extra-thick MDF and some UHMW, I decided to make use of those. As you can see, it is a bit oversized for tenons - I made it large enough to also use for raising panels.

I used 1 3/8" MDF for the main body as well as the outrigger. I was concerned all the extra weight would make it cumbersome to use, but those concerns were unfounded. It _is_ very heavy, but I waxed the inside faces and put UHMW sliders on the bottom and it glides pretty well. The extra heft certainly has made it feel very sturdy and accurate.

I used it to plow a 2" deep groove (dado?) in the end of a table leg for a lap joint using my shiny new 8" dado - I had to go slowly, but the result was perfect.

Great way to spend a vacation day :>

I used 1 3/8" MDF for the main body as well as the outrigger. I was concerned all the extra weight would make it cumbersome to use, but those concerns were unfounded. It _is_ very heavy, but I waxed the inside faces and put UHMW sliders on the bottom and it glides pretty well. The extra heft certainly has made it feel very sturdy and accurate.

I used it to plow a 2" deep groove (dado?) in the end of a table leg for a lap joint using my shiny new 8" dado - I had to go slowly, but the result was perfect.

Great way to spend a vacation day :>