My jointer layed down on me last night and need to buy another one. I have a 6", but while I am buying I would like a larger capacity. I can't afford a lot, but looking at somewhere between $600 to $800 I am thinking. I found this one at Woodcraft. It is below my budget but don't know much about Jet and wanted to know if anyone has this one. 10 inch capacity is alot more than I have now. I can't afford 12" that I want (you know how that goes). Or if anyone has another option, I am open. I have already searched CL, but didn't find much.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

With that said, I am looking at a Shop Fox W1679 & W1745 & Grizzly G0452P & G0604X (which is a parallelagram and not exactly sure what the advantage of that is)http://www.grizzly.com/products/6-Parallelogram-Jointer/G0604X

I've seen the 10" JET (JJP-10BTOS), and it is definitely a specialty machine. Its 10" capacity is huge for a jointer, but small for a planer. Also, it is light-weight, with modest power. At the risk of gross generalization and doing the machine injustice, to me it's a solution for people with a very small shop that generally build jewelry boxes, cutting boards, etc. Long boards for cabinetry would be a challenge on this machine.With that said, I am looking at a Shop Fox W1679 & W1745 & Grizzly G0452P & G0604X (which is a parallelagram and not exactly sure what the advantage of that is)

The Grizzly/ Shop Fox machines you mentioned are solid 6" jointers. I used to have the G0452, and it performed well. As for the difference between dovetailed and paralleogram jointers, see the following from the woodweb archive:

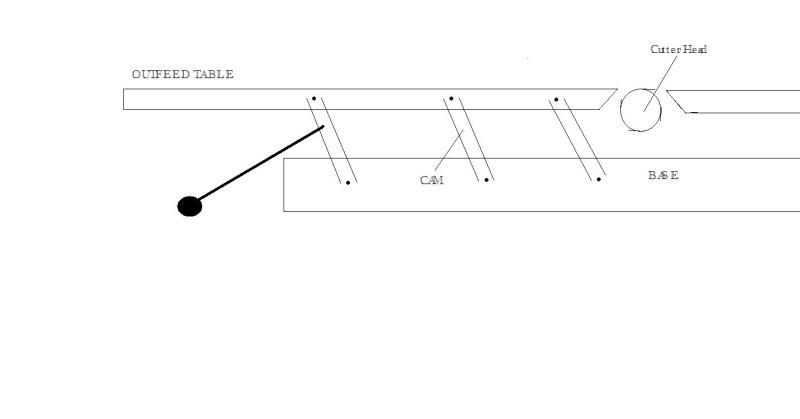

This image from woodworkingtalk might help:A parallelogram jointer offers four point adjustability for each table. Dovetailed ways units can only be shimmed to account for sag. Also p-tables can be removed and ground and reinstalled if it's warped. D-table jointers must be ground as an entire unit. There really is no real adjustment on d-tables except shimming. P-table has a slightly tighter throat because of the table movement but it's an insignificant reason. P-tables are much more complicated to take off compared to d-tables. My personal favorite table design is the inclines on old Olivers, and Crescents. They are the simplest and best to remove and adjust.

Several people here on the site have the Ridgid JP0610 and like the machine. At $429 (plus tax), it's very reasonably priced.

has anyone seen this one on CL

It was an el cheapo from HF that was just getting me by while I got started.

in that case BUY NEW!!!!!:gar-Bi keep an eye on CL. ya might get lucky.:icon_thum

did you see the above post of mine for the powermatic on CL for $375?

Trying to find out what model it is

CALL NOW!!!!!!! bet you could get it for 350 and then gloat.

I dream of the powermatic since it has longer beds then others... I have the ridged and seems to do the job but the longer the beds the better

Holy cow! You must be doing something right. Maybe something like this? http://www.grizzly.com/products/8-x...ad-and-Mobile-Base-Polar-Bear-Series-/G0656PX

or maybe you can find a used 12" In any event. I'd go for the long tables and the spiral cutter head. Have fun shopping.

bobby g

or maybe you can find a used 12" In any event. I'd go for the long tables and the spiral cutter head. Have fun shopping.

bobby g

My F-in-law just upped our budget for a new jointer to $1500. yea!!!

wow congrats... how do you find a F-in-law like that.... does your wife have a sister available

A bunch of us here got the ShopFox 1741 8" jointers ~5 years ago. I have been very happy with mine. I think they have a Shelix head version now which would use most of your $1500.

I'd look around for a 12". I had a 6" then upgraded to the Grizzly G0609 12". It's nice being at the lumber yard and being able to purchase wide boards and not worry about ripping them down to joint them! I've heard good things about the spiral/shelix heads, but I wouldn't spend the money on them (unless it's a great deal!). I'd rather have the spiral/shelix head on a planer since I'll plane both sides after jointing one side.

Good luck!

Good luck!

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 310

- Replies

- 0

- Views

- 233

- Replies

- 1

- Views

- 304

LATEST FOR SALE LISTINGS

-

For Sale Electrical supplies (Are you building a new shop?)

- Started by DSWalker

- Replies: 0

-

-

-

-

For Sale Powermatic PM 701 Mortiser, 4 Powermatic Chisels (3 unused in wrapper) $550

- Started by frankc4113

- Replies: 0