Must have a hundred drill bits from micro to 1" diameter, all dull as can be. Oldtimers in the days before modern gadgets must have sharpened their bits by hand, but I can't find a description of how. Please don't tell me to buy some sharpening machine, I'm broke. But I have all kinds of stones and grinders and a neat little electric hone and lots of time on my hands. Any info much appreciated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

I learned how to sharpen bits in Machinist school many years ago.

Look in some of the machinist sites.

I'll do a search and see what I can find on line.

Oh and welcome to the site!

Look in some of the machinist sites.

I'll do a search and see what I can find on line.

Oh and welcome to the site!

I have sharpened so many I can sharpen them with my eyes closed(almost) :gar-La; it just takes some practice,what I would do is try and find somebody close that could show you how,or maybe a mach shop that would sharpen them for you for a decent charge.Wish I could be a bit more help.

I sharpened my drill bits by hand for years, until I picked up a good deal on a Darex Drill doctor. Now I only have to hand sharpen the ones over 3/4".

Personally I prefer a 12" disc sander for sharpening bits, but a good grinding wheel will do. It's not that hard to do once you pick up the basics, but there is some skill involved.

Keep a pail of water handy for cooling the bits while sharpening so that the tips don't lose their temper.

Start with the articles that Mike digs up, and if you need more instruction you can bring some bits with you and stop by the farm and I'll walk you through the steps.

Scott

Personally I prefer a 12" disc sander for sharpening bits, but a good grinding wheel will do. It's not that hard to do once you pick up the basics, but there is some skill involved.

Keep a pail of water handy for cooling the bits while sharpening so that the tips don't lose their temper.

Start with the articles that Mike digs up, and if you need more instruction you can bring some bits with you and stop by the farm and I'll walk you through the steps.

Scott

I tried to find a video because that would be best, but here is an article from wood craft.

http://www.woodcraft.com/Articles/Articles.aspx?articleid=267

Here's some more...

http://www.instructables.com/id/Sharpen-Your-Drill-Bits/

This video is not very good but you get the basic idea.

http://www.youtube.com/watch?v=pW7kGFcM2sc

It really is better to have someone show you and watch you do a few to see that you have it right. But, if you totally ruin a couple and learn by trial and error that ain't too bad.

One thing that helps a lot is to get a drill gauge to check the angle and length of each face of the drill tip.

http://www.amazon.com/each-General-...ie=UTF8&s=miscellaneous&qid=1260529888&sr=8-2

I like the Starrett drill angle gauge better but couldn't find a link for it.

Found the Starrett gauge.

http://www.starrett.com/pages/1569_protractors_angle_measurements.cfm

http://www.woodcraft.com/Articles/Articles.aspx?articleid=267

Here's some more...

http://www.instructables.com/id/Sharpen-Your-Drill-Bits/

This video is not very good but you get the basic idea.

http://www.youtube.com/watch?v=pW7kGFcM2sc

It really is better to have someone show you and watch you do a few to see that you have it right. But, if you totally ruin a couple and learn by trial and error that ain't too bad.

One thing that helps a lot is to get a drill gauge to check the angle and length of each face of the drill tip.

http://www.amazon.com/each-General-...ie=UTF8&s=miscellaneous&qid=1260529888&sr=8-2

I like the Starrett drill angle gauge better but couldn't find a link for it.

Found the Starrett gauge.

http://www.starrett.com/pages/1569_protractors_angle_measurements.cfm

I learned how to sharpen drill bits while I was a mold makers apprentice, lots of water passages in a plastic mold and almost all of them are cut with twist drills.

If these are regular twist bits, not brad point, this sounds like a job for Drill Doctor. See if anybody in your area has one. I do, but I'm not in your neck of the woods. By the way, you can use the machine on brad point bits and they will be really sharp afterwards... but they won't be brad point any longer.

Keep a pail of water handy for cooling the bits while sharpening so that the tips don't lose their temper.

Back in my machinist days I used to do this too. I've since learned hot HSS can develop micro-cracks from doing this, which can significantly shorten the time it takes before you have to sharpen again.

What I've learned (assuming you're right handed) is when the fingers of your left hand start to feel uncomfortably warm, back off and let the bit air cool until it's comfortable to hold again. If the end of the bit starts to turn brown or blue, you're using too much pressure. And you have your left hand is too far back from the end of the bit, or you'd have noticed it was getting hot before it changed color.

And I agree with Mike, the Starrett gauge is the best. Mines close to 40 years old and still in use.

Len

Right, if you can't keep a steady flow of water or coolant on the grindstone then keep your finger close to the edge and let the bit cool before you proceed.

If you see ANY color develop back off!

A light touch is all you need, if you think you need to force the bit into the stone then the stone needs dressing or you are using too fine of a stone. Go to a 36 grit for quick material removal.

If you see ANY color develop back off!

A light touch is all you need, if you think you need to force the bit into the stone then the stone needs dressing or you are using too fine of a stone. Go to a 36 grit for quick material removal.

Welcome aboard.

I sharpen my own with some amount of limited success. Had a guy 40 + years ago show me how and I still remember it to this day. Basically its in the 'feel' and twisting of the drill as you grind it. First some info on understanding twist drill nomenclature (pages 16, 18, 19)

http://www.presto-tools.co.uk/files/drills-page.pdf

It will be easier to learn sharpening by doing it on a bigger drill bit first. 1/2" to 3/4" will give you something to 'look at' while grinding. You will be able to tell what you are doing right/wrong on the bigger bit. Page 16 of the above link gives the important points.

Here is another link showing one type of gage and how to grind the bit.

http://www.tpub.com/content/construction/14251/css/14251_319.htm

and another link to help

http://www.gunreports.com/special_r...s-techniques-drill-bits-sharpening1633-1.html

Do a search for 'drill point gage' and you will find some others.

Here is a link showing one being used

http://www.tpub.com/content/construction/14256/css/14256_94.htm

Even if you would use a drill doctor its nice to know what is going on to get a good sharp drill.

I can tell the difference between a good quality drill and the cheap overseas ones when using them in my metal lathe. The cheap ones only cut with one flute/cutting edge. Problem is I can't afford the expensive bits and don't want to mess with the new cheap ones to make them better so I just plod along.

BTW. IF you want to drill a slightly oversized hole you can actually make the mistakes and it will force the bit to drill a bigger hole.

I sharpen my own with some amount of limited success. Had a guy 40 + years ago show me how and I still remember it to this day. Basically its in the 'feel' and twisting of the drill as you grind it. First some info on understanding twist drill nomenclature (pages 16, 18, 19)

http://www.presto-tools.co.uk/files/drills-page.pdf

It will be easier to learn sharpening by doing it on a bigger drill bit first. 1/2" to 3/4" will give you something to 'look at' while grinding. You will be able to tell what you are doing right/wrong on the bigger bit. Page 16 of the above link gives the important points.

Here is another link showing one type of gage and how to grind the bit.

http://www.tpub.com/content/construction/14251/css/14251_319.htm

and another link to help

http://www.gunreports.com/special_r...s-techniques-drill-bits-sharpening1633-1.html

Do a search for 'drill point gage' and you will find some others.

Here is a link showing one being used

http://www.tpub.com/content/construction/14256/css/14256_94.htm

Even if you would use a drill doctor its nice to know what is going on to get a good sharp drill.

I can tell the difference between a good quality drill and the cheap overseas ones when using them in my metal lathe. The cheap ones only cut with one flute/cutting edge. Problem is I can't afford the expensive bits and don't want to mess with the new cheap ones to make them better so I just plod along.

BTW. IF you want to drill a slightly oversized hole you can actually make the mistakes and it will force the bit to drill a bigger hole.

Back in my machinist days I used to do this too. I've since learned hot HSS can develop micro-cracks from doing this, which can significantly shorten the time it takes before you have to sharpen again.

Len, thanks for the info re the cracking - I was not aware of that. Do you know what temp that the HSS needs to reach before it will crack during rapid cooling? I'm wondering if it would be possible to cool the bit earlier in the process, and more frequently, versus the time that it takes to wait while it air cools.

Scott,

Not sure exactly what the temperature is but if your fingers are feeling uncomfortably hot, and the bit has not changed color, you've reached it. I don't do production work anymore, so I save the dull bits until "sharpening day", and work on a chisel or plane blade while a drill bit cools off.

Len

Not sure exactly what the temperature is but if your fingers are feeling uncomfortably hot, and the bit has not changed color, you've reached it. I don't do production work anymore, so I save the dull bits until "sharpening day", and work on a chisel or plane blade while a drill bit cools off.

Len

Scott,

Not sure exactly what the temperature is but if your fingers are feeling uncomfortably hot, and the bit has not changed color, you've reached it. I don't do production work anymore, so I save the dull bits until "sharpening day", and work on a chisel or plane blade while a drill bit cools off.

Len

Len, thanks for the info. Most of the time I'm cooling the bit before my fingers get hot - usually it's around 5 - 7 seconds on the sanding disc / grinding wheel, and then dipping in cooling water.

I don't do many by hand since I picked up the Darex units - just my larger (3/4" - 1-1/2" stuff).

What brand of bits do you prefer? I discovered "Magnum Series" bits by Norseman Drill and Tool around 25 years ago, and have never found anything better for general steel work. These bits will drill many of the stainless grades, spring steel, etc, yet are not brittle like cobalt bits. Before that I was using Greenlee and Cleveland Twist bits.

Scott,

My metal working bits are a mixed bag from my days as a machinist, And I haven't been a paid for machine work in over 40 years. Actually my "best" metal drilling bits, from the days I worked in a ship yard, are 'jobber' length bits from Western Auto.

There was a time they actually carried real "Made in America" tools, and drill bits up to 1-1/4in diameter. I sure do miss those days.

Len

My metal working bits are a mixed bag from my days as a machinist, And I haven't been a paid for machine work in over 40 years. Actually my "best" metal drilling bits, from the days I worked in a ship yard, are 'jobber' length bits from Western Auto.

There was a time they actually carried real "Made in America" tools, and drill bits up to 1-1/4in diameter. I sure do miss those days.

Len

use a grinder

For years, I sharpened twist drills on my grinder using the rest that had an angled groove in it and just making an even grinding of the tip. The angle groove is set for drills. Maybe not as good a drill doctor, but the drills were always a whole better than they were.

For years, I sharpened twist drills on my grinder using the rest that had an angled groove in it and just making an even grinding of the tip. The angle groove is set for drills. Maybe not as good a drill doctor, but the drills were always a whole better than they were.

Hey guys, Mae West says "I have all kinds of stones and grinders and a neat little electric hone and lots of time on my hands." Maybe that's the woodworker equivalent of saying "Why don't you come up and see me some time?" (To show her how to sharpen bits on her stones and grinders of course.)

I have all kinds of stones and grinders and a neat little electric hone and lots of time on my hands.

To learn metal cutting bit sharpening, observe the cutting end carefully. On a stopped grinder, practice rotating the bit along the cutting edge observing the twist and roll necessary to keep the grinding wheel in contact with the ramp at all times. Keep a fairly good bit of good size (like 3/8") around for observations of how it should look when finished.

For wood boring (brad point) bits under 1/2", get an abrasive cut-off wheel of about 1/32nds thickness from an industrial mail-order place for under $10.00 and use that. Rig a little platform on the tool rest. Clamp a magnifying glass to the eyeshield and go for it. I prefer the Norton A60 OBNA2 cut off wheel.

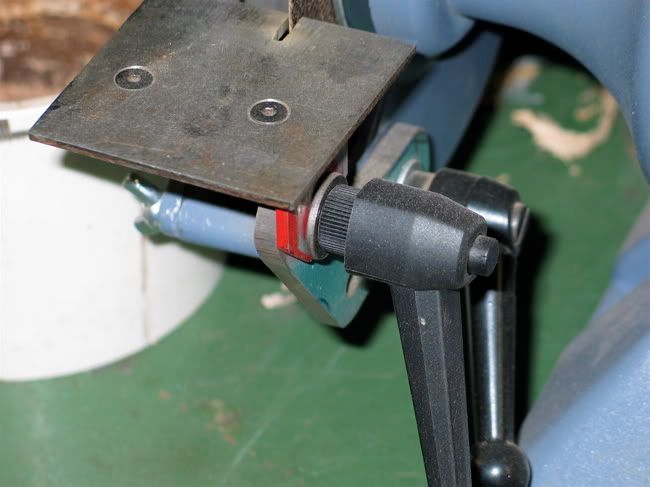

Here's a rig on a cheapie Baldor 6" grinder with a locking handle instead of a nut.

Here's a scan of a rig I used to use.

Here's the rig showing grinding the back side of the brad point

Yet another brad point sharpening rig on another grinder

- Status

- Not open for further replies.

LATEST FOR SALE LISTINGS

-

-

-

SOLD -- $75: Gast moa v113 Vacuum Pump Veneer, 60" bag and board

- Started by peterdnight

- Replies: 1

-

GONE: Gladiator 5 cleats, 10 hangers, Paper Towel and Shelf

- Started by peterdnight

- Replies: 3

-

SOLD -- $100 Makita mac700 portable air + grex pin nailer + 2 others + 50' hose

- Started by peterdnight

- Replies: 1