So, I built a massive heavy, stable workbench. 32 high. Great for things I need to be above for leverage. But, somehow I do 90% of my work on my outfeed ( 38 inch) as it is high enough I can see it and I don't have to bend over as much.

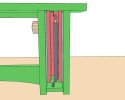

So, I am looking for ideas on how to make the bench adjustable height and retain it's stability. Nothing worse than a bench that wiggles when you are trying to cut a dovetail. A simplistic solution would be a topper/vise I could clamp in either the end or face. One more big bulky thing I don't have room to store! 6 to 8 inch lift is desired. Yea the bench weighs about 400 Lbs.

So, I am looking for ideas on how to make the bench adjustable height and retain it's stability. Nothing worse than a bench that wiggles when you are trying to cut a dovetail. A simplistic solution would be a topper/vise I could clamp in either the end or face. One more big bulky thing I don't have room to store! 6 to 8 inch lift is desired. Yea the bench weighs about 400 Lbs.