Nice work! The king Seeley era Craftsman, (like yours) is what solidified their reputation at their peak. I had and restored the same press, (though a floor model) several sears ago, and apart from the use of a little pot metal in the handwheel/ hub, it was built like a tank. I only upgraded to a Delta Rockwell because I could, there really wasn't an upgrade in quality/ serviceability.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1956 Craftsman Drill Press Rebuild - Completed

- Thread starter NYTransplant

- Start date

Thanks!!Nice work! The king Seeley era Craftsman, (like yours) is what solidified their reputation at their peak. I had and restored the same press, (though a floor model) several sears ago, and apart from the use of a little pot metal in the handwheel/ hub, it was built like a tank. I only upgraded to a Delta Rockwell because I could, there really wasn't an upgrade in quality/ serviceability.

It certainly is built like a tank!!! A lot of cast iron. I'm looking forward to replacing my existing small Craftsman drill press and using this one.

Heck yeah! A 1956 Custom Hot RodOh man... going for the sporty look!

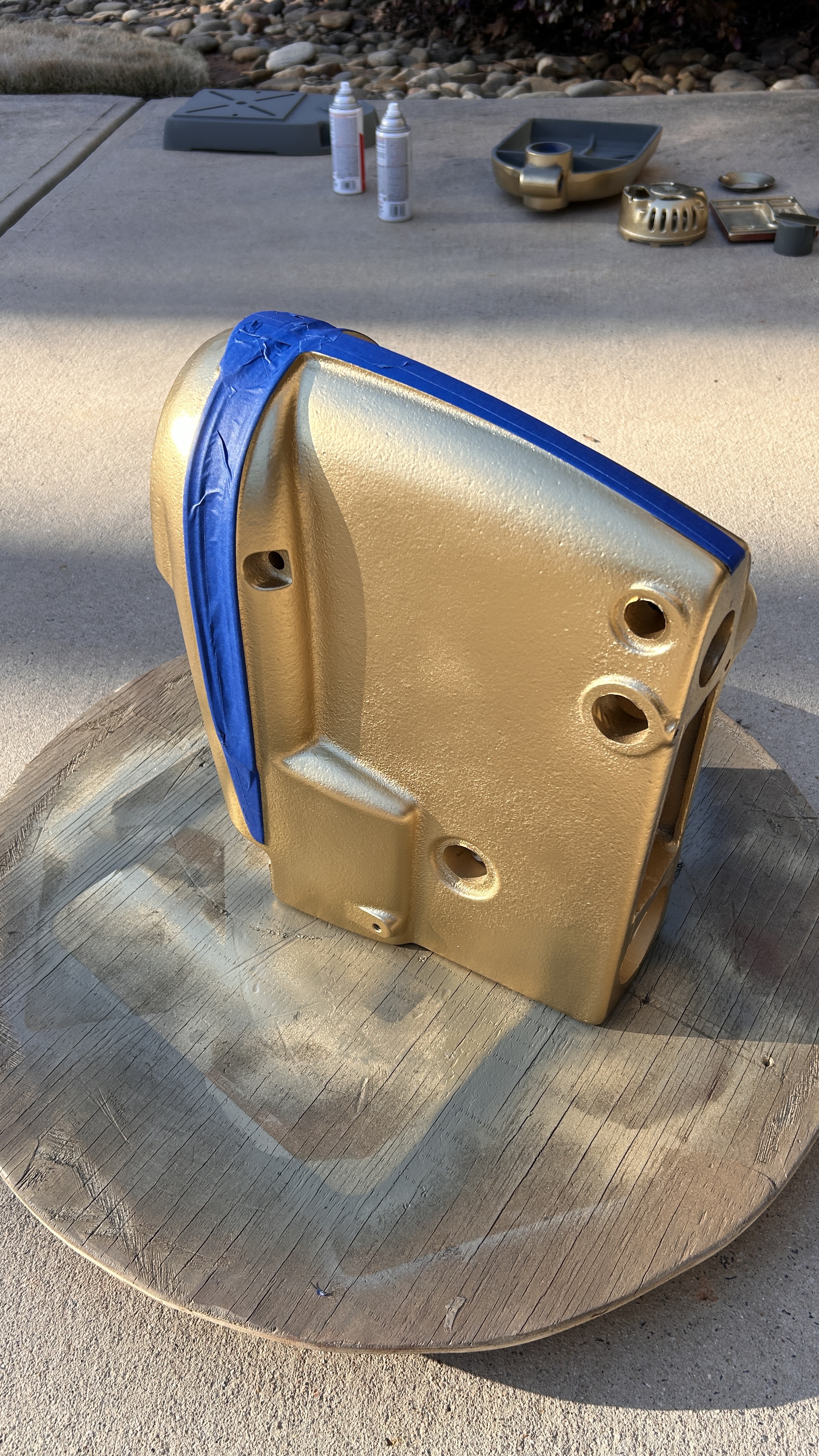

The head is painted

I figured since I was using a gold base coat, I’d mask it off to see what it would look like with a gold accent.

I kinda like it. I think I’ll leave it this way.

Although the first thing I thought of when I pulled off the tape was this…

Not exactly the look I was going for.

I figured since I was using a gold base coat, I’d mask it off to see what it would look like with a gold accent.

I kinda like it. I think I’ll leave it this way.

Although the first thing I thought of when I pulled off the tape was this…

Not exactly the look I was going for.

L0ve the pvc tube Idea!! I will borrow it for when I do mine{I’ve had it for 40 years now and was going to strip it down when I first got it.Cleaning some of the smaller parts

The small parts soaked in Simple Green for a day, then I buffed most of them on a brass wire wheel and buffing wheel. The "chrome parts got a wipe down and polish with Flitz.

For the close tolerance parts, I really didn't give them more than a wipe down and a spray of oil.

Before:

View attachment 224913

After:

View attachment 224920

There's some pitting on the chrome, but they cleaned up relatively well for 68 years old ;-)

I also soaked the column in Evaporust overnight. I capped off a 3" PVC pipe and a gallon covered the entire height of the benchtop column.

View attachment 224915

Before:

View attachment 224916

After soaking:

View attachment 224917

And after a quick machine buffing with rubbing compound and a coat of wax:

View attachment 224918

The table is currently soaking in Simple Green and will come out next. There are still quite a few parts to clean up as well.

More to come...

That was a suggestion from @Rick_BL0ve the pvc tube Idea!! I will borrow it for when I do mine{I’ve had it for 40 years now and was going to strip it down when I first got it.

Who stole it from someone else - just can't remember whoThat was a suggestion from @Rick_B

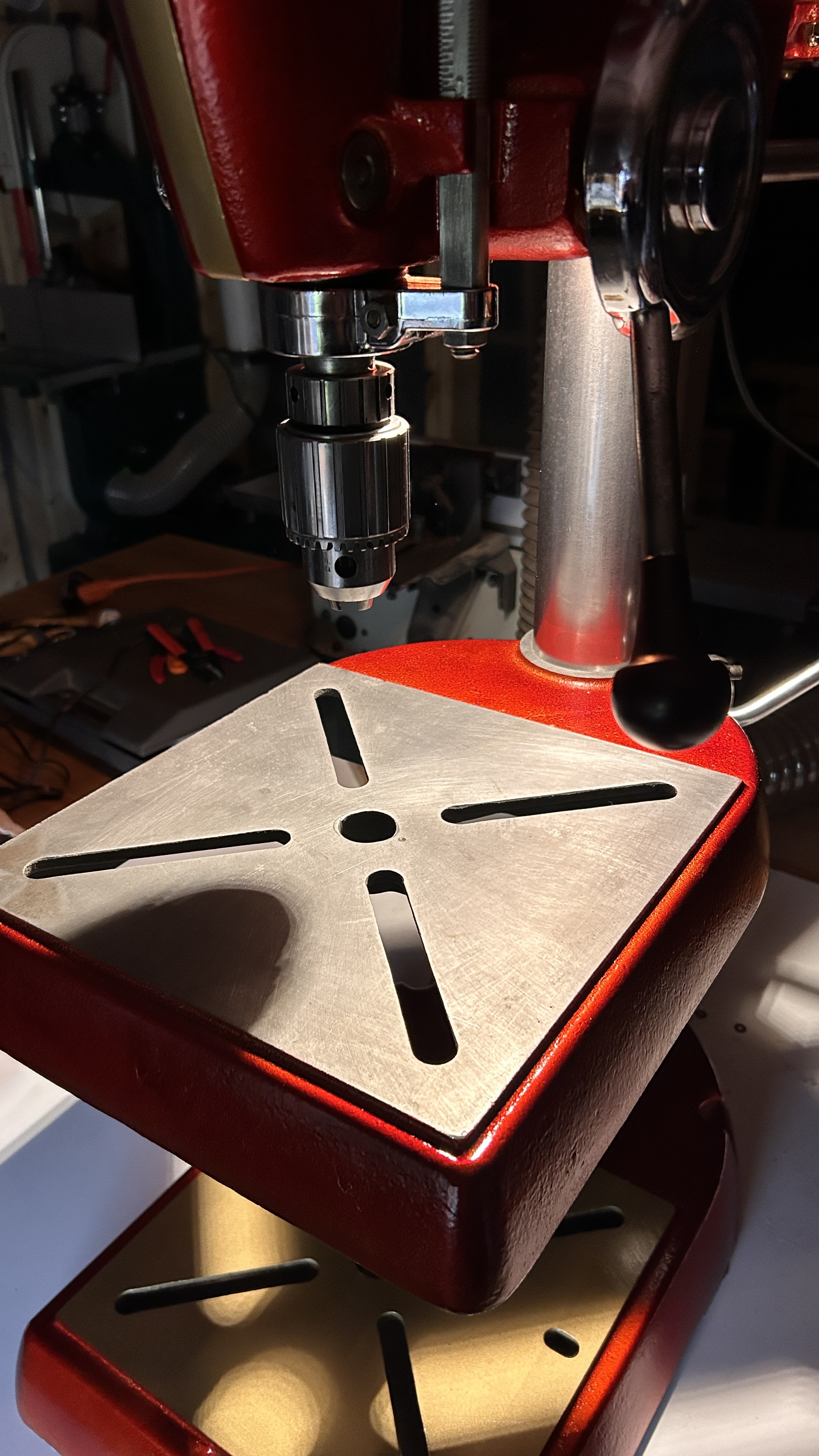

I installed the trim on the head to see what it would look like. It did break up the gold along the sides.

Also, the table is done. You can see the base has no red paint yet. I plan to tape off the flat surface and keep it gold. It's the last thing to paint.

And the motor endcaps are complete. I taped off the edges to give them a two-tone look.

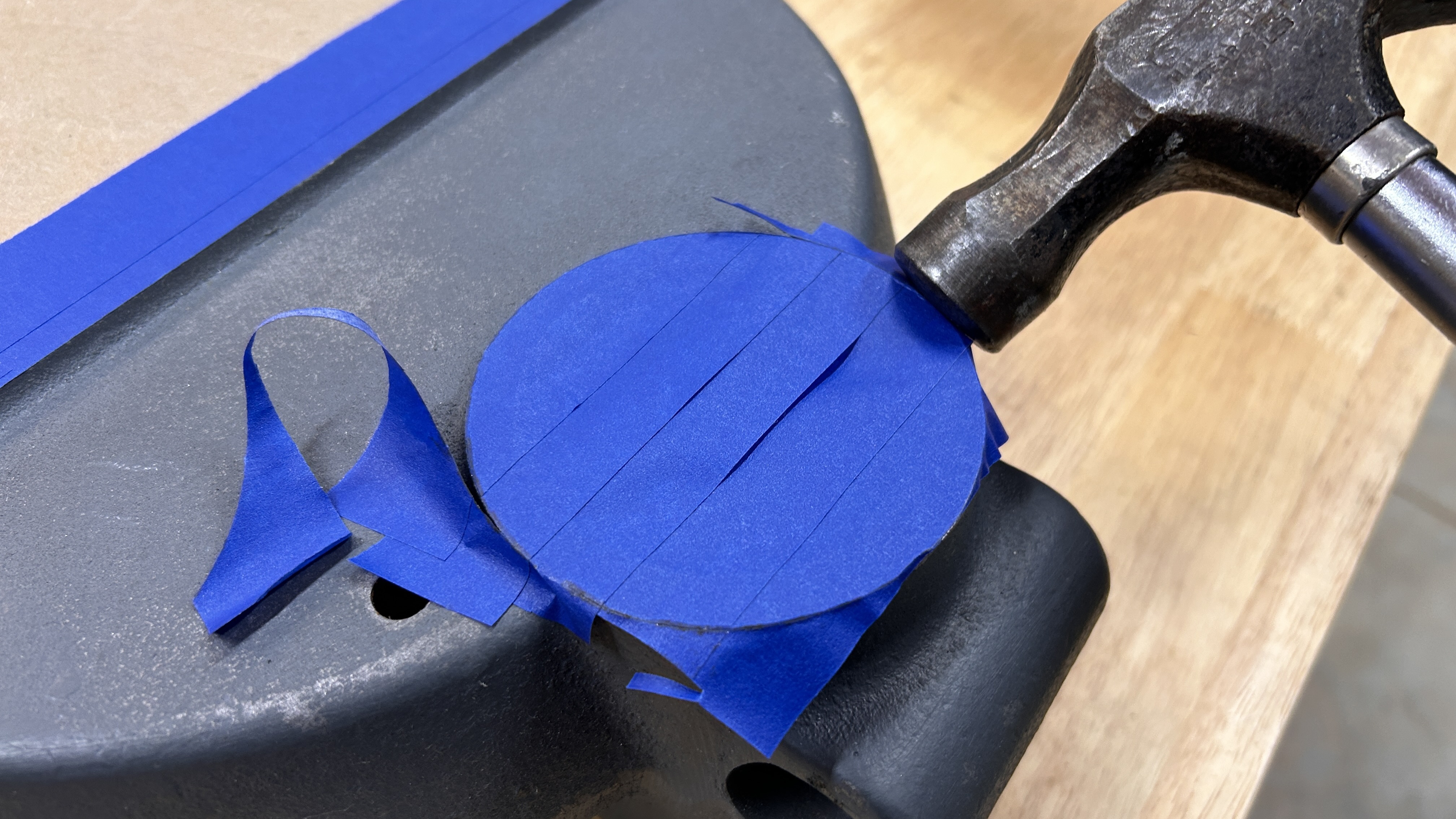

By the way, a trick to trim the round bosses on the table and base is to gently tap the sharp edge of the boss with a hammer to cut the tape rather than try to trim it with a knife.

Also, the table is done. You can see the base has no red paint yet. I plan to tape off the flat surface and keep it gold. It's the last thing to paint.

And the motor endcaps are complete. I taped off the edges to give them a two-tone look.

By the way, a trick to trim the round bosses on the table and base is to gently tap the sharp edge of the boss with a hammer to cut the tape rather than try to trim it with a knife.

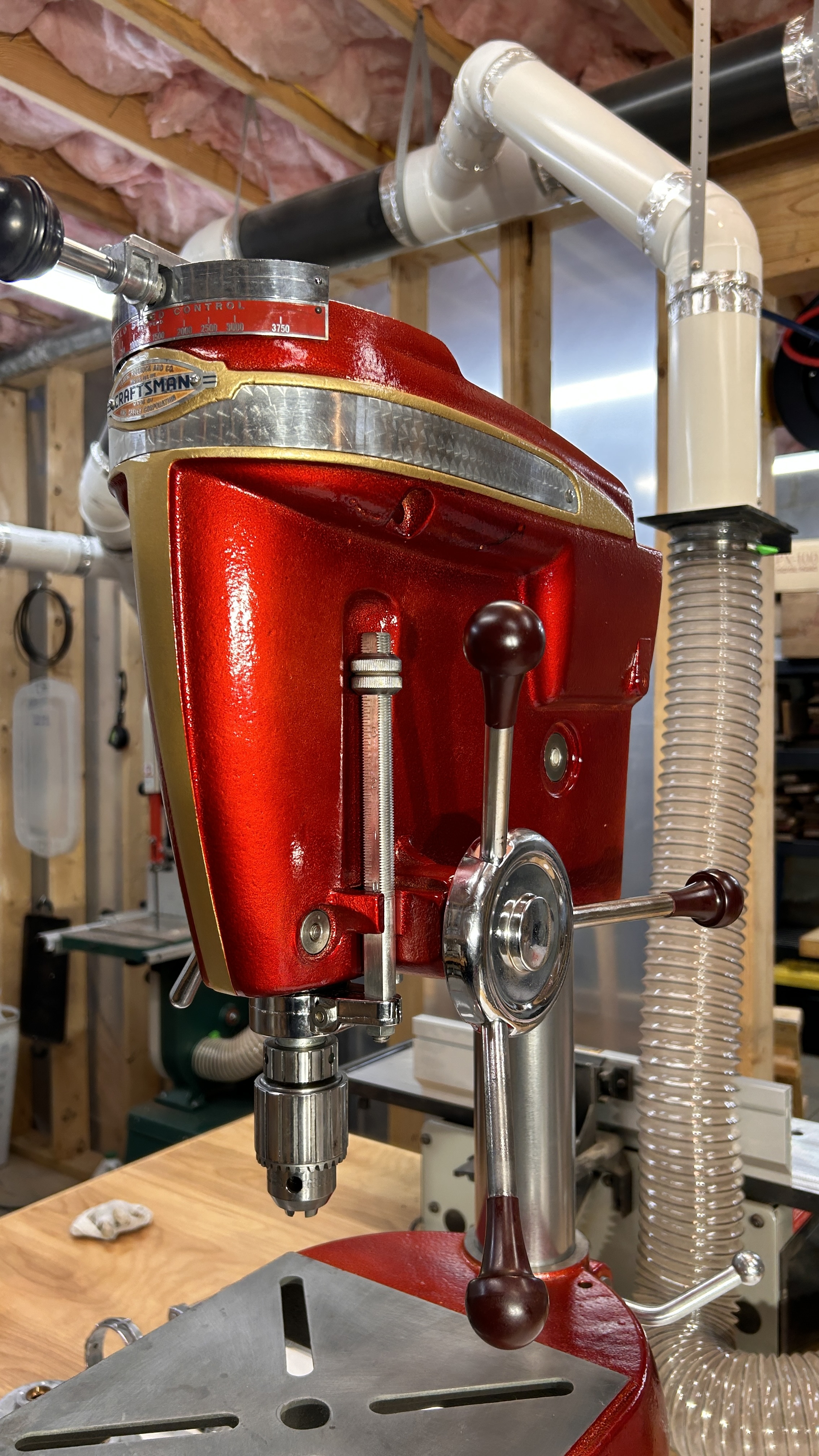

It’s starting to look like a drill press again

I still have a little way to go, but I should finish in a day or so.

I ended up putting a few coats of clear over the paint because it didn’t look like it would hold up to heavy use.

A few subassemblies went together today. I still have to assemble the quill.

I still have a little way to go, but I should finish in a day or so.

I ended up putting a few coats of clear over the paint because it didn’t look like it would hold up to heavy use.

A few subassemblies went together today. I still have to assemble the quill.

Finished up the Head:

Today was a light day. Since it's Saturday, I spent most of my morning at Cars & Coffee.

I installed the bearings in the quill assembly and mounted everything else in the head.

Pressing the bearings on was a piece of cake with the press...

Once that was assembled, I installed the chuck:

... installed the quill, quill lock, and depth gauge, and here is the final result.

Still to go is reassembling and installing the motor, buying new belts and installing the Vari-Slo drive, and finishing up by fabricating and installing an internal work light.

Today was a light day. Since it's Saturday, I spent most of my morning at Cars & Coffee.

I installed the bearings in the quill assembly and mounted everything else in the head.

Pressing the bearings on was a piece of cake with the press...

Once that was assembled, I installed the chuck:

... installed the quill, quill lock, and depth gauge, and here is the final result.

Still to go is reassembling and installing the motor, buying new belts and installing the Vari-Slo drive, and finishing up by fabricating and installing an internal work light.

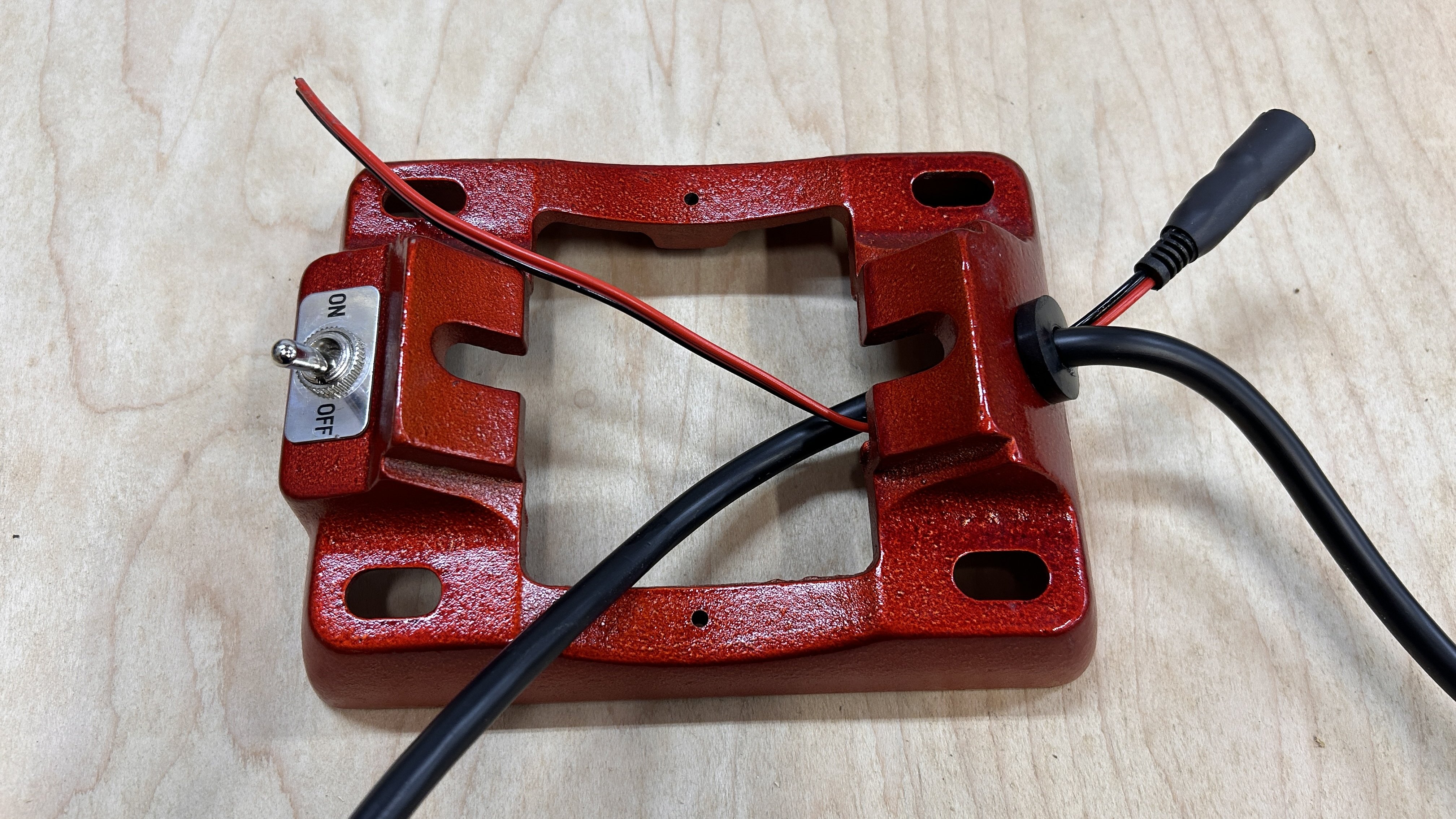

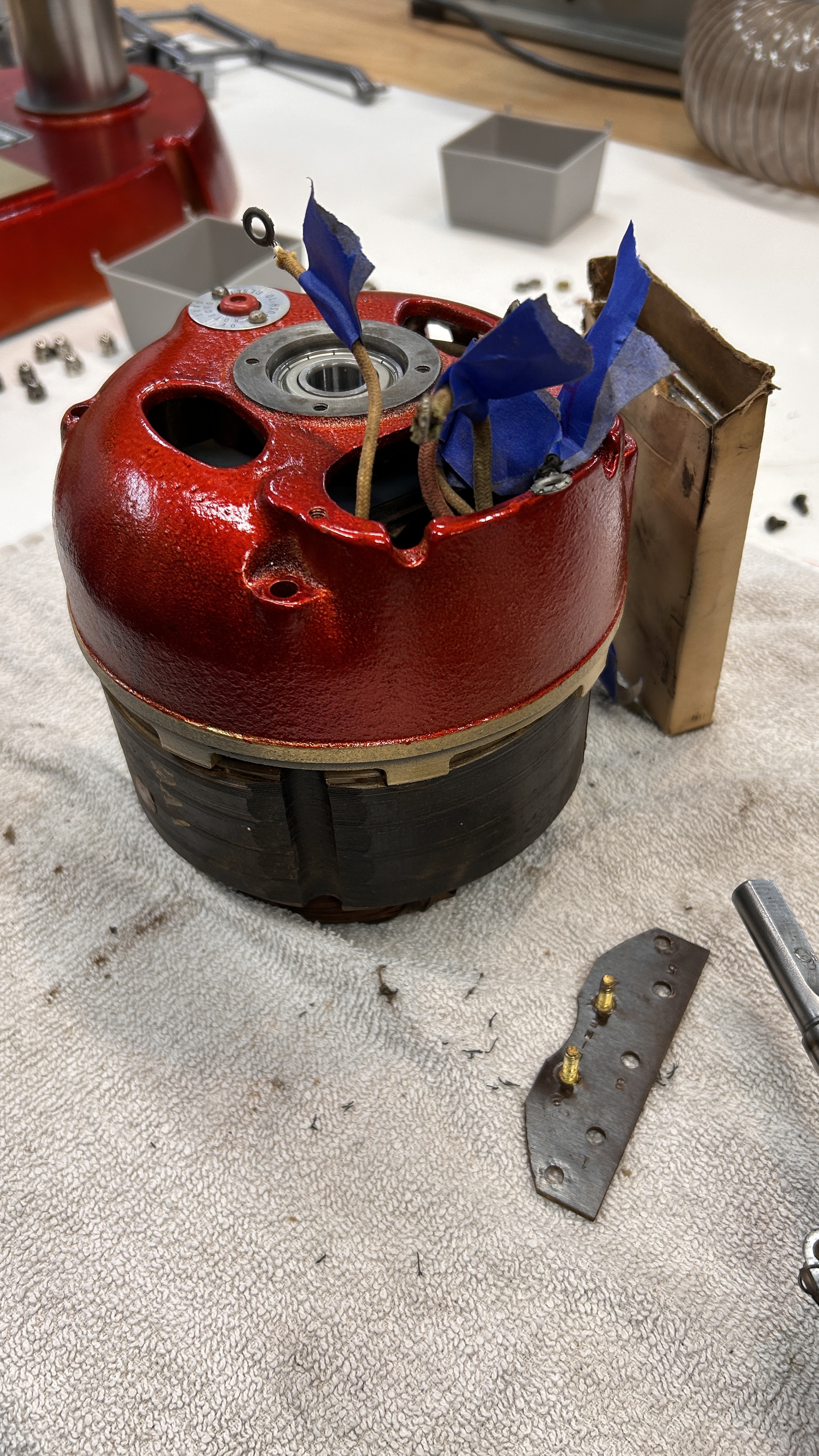

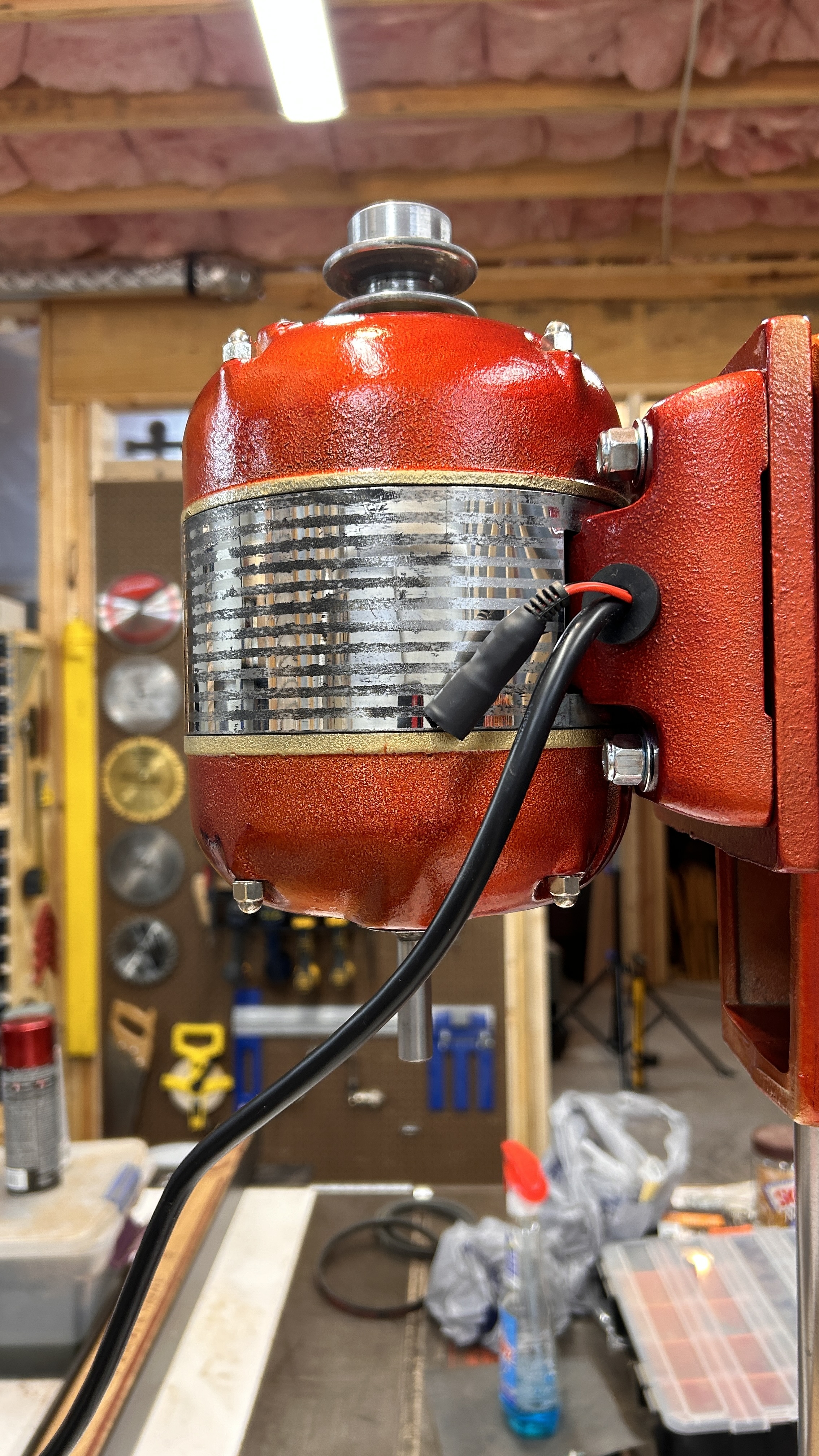

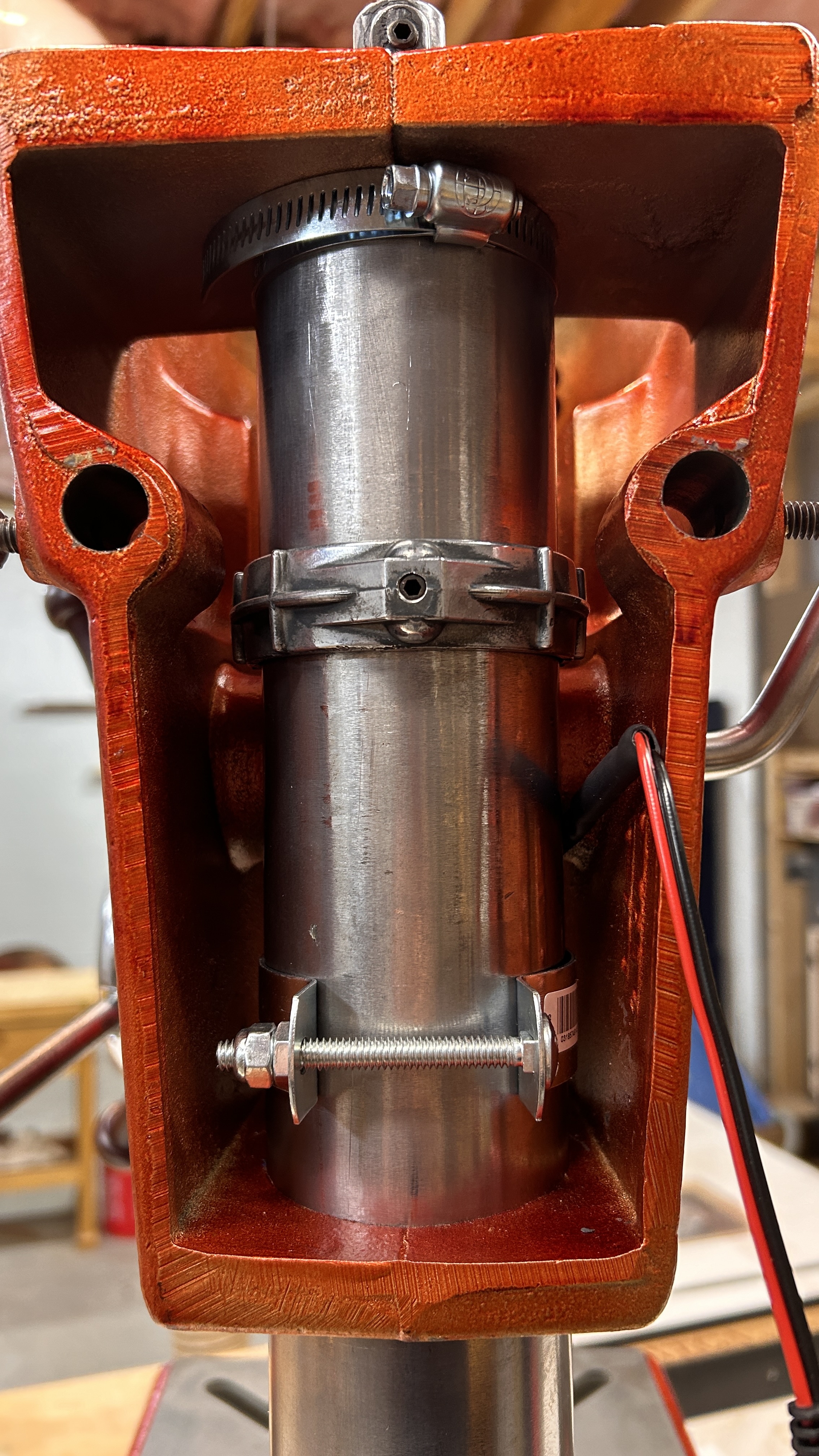

Motor Assembled and Mounted...

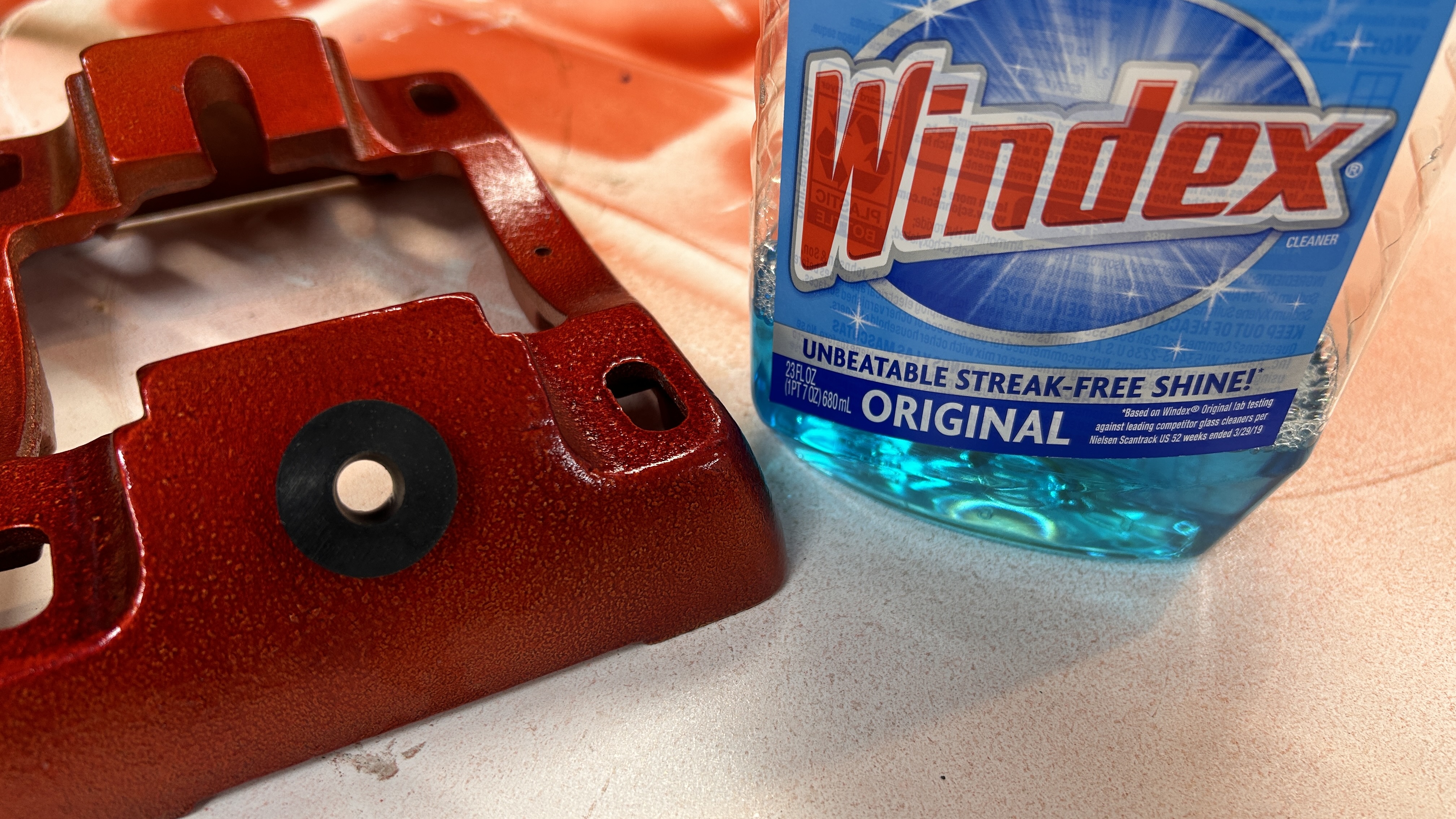

Took my time assembling the motor today. You can't be too careful with 80 year old wires. The Neutral wire coming straight off the windings was super stiff and difficult to work with, but it all went together without incident.

Added a three-wire cord to ground the motor. I couldn't find the perfect sized grommet, so the new one was a little tight. But as we all learned in the movie "My Big Fat Greek Wedding", Windex can fix pretty much anything... installing a grommet and squeezing cables through it... yep.

The smaller wire is for the light kit I'm fabricating. I happened to have a few male/female pairs laying around in my electrical stash.

The not so fun part... snaking this old wiring through the places it's supposed to go without damaging it.

And the motor, completed and mounted. It actually ran when I plugged it in!

Took my time assembling the motor today. You can't be too careful with 80 year old wires. The Neutral wire coming straight off the windings was super stiff and difficult to work with, but it all went together without incident.

Added a three-wire cord to ground the motor. I couldn't find the perfect sized grommet, so the new one was a little tight. But as we all learned in the movie "My Big Fat Greek Wedding", Windex can fix pretty much anything... installing a grommet and squeezing cables through it... yep.

The smaller wire is for the light kit I'm fabricating. I happened to have a few male/female pairs laying around in my electrical stash.

The not so fun part... snaking this old wiring through the places it's supposed to go without damaging it.

And the motor, completed and mounted. It actually ran when I plugged it in!

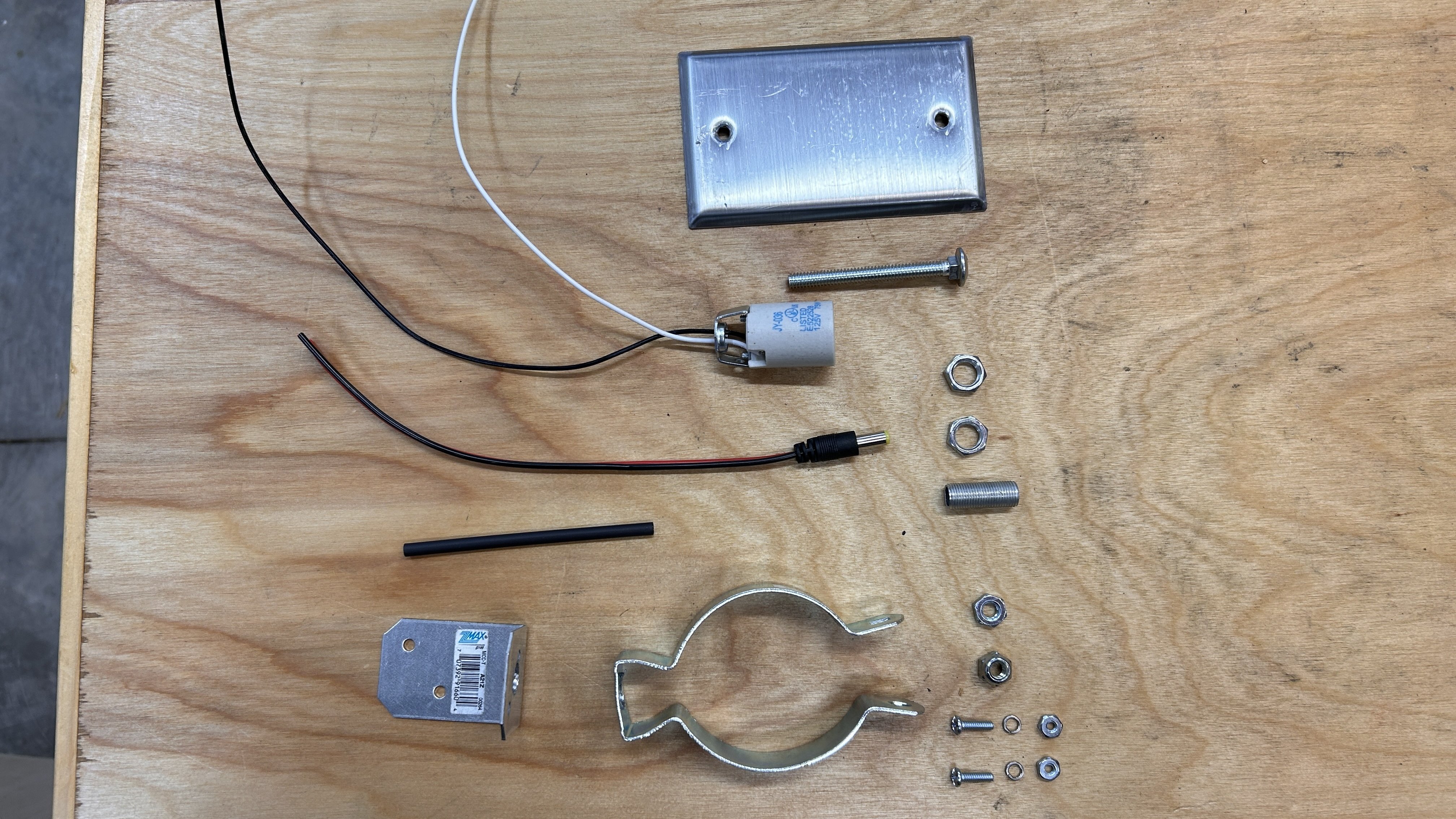

Light Kit Completed and Installed

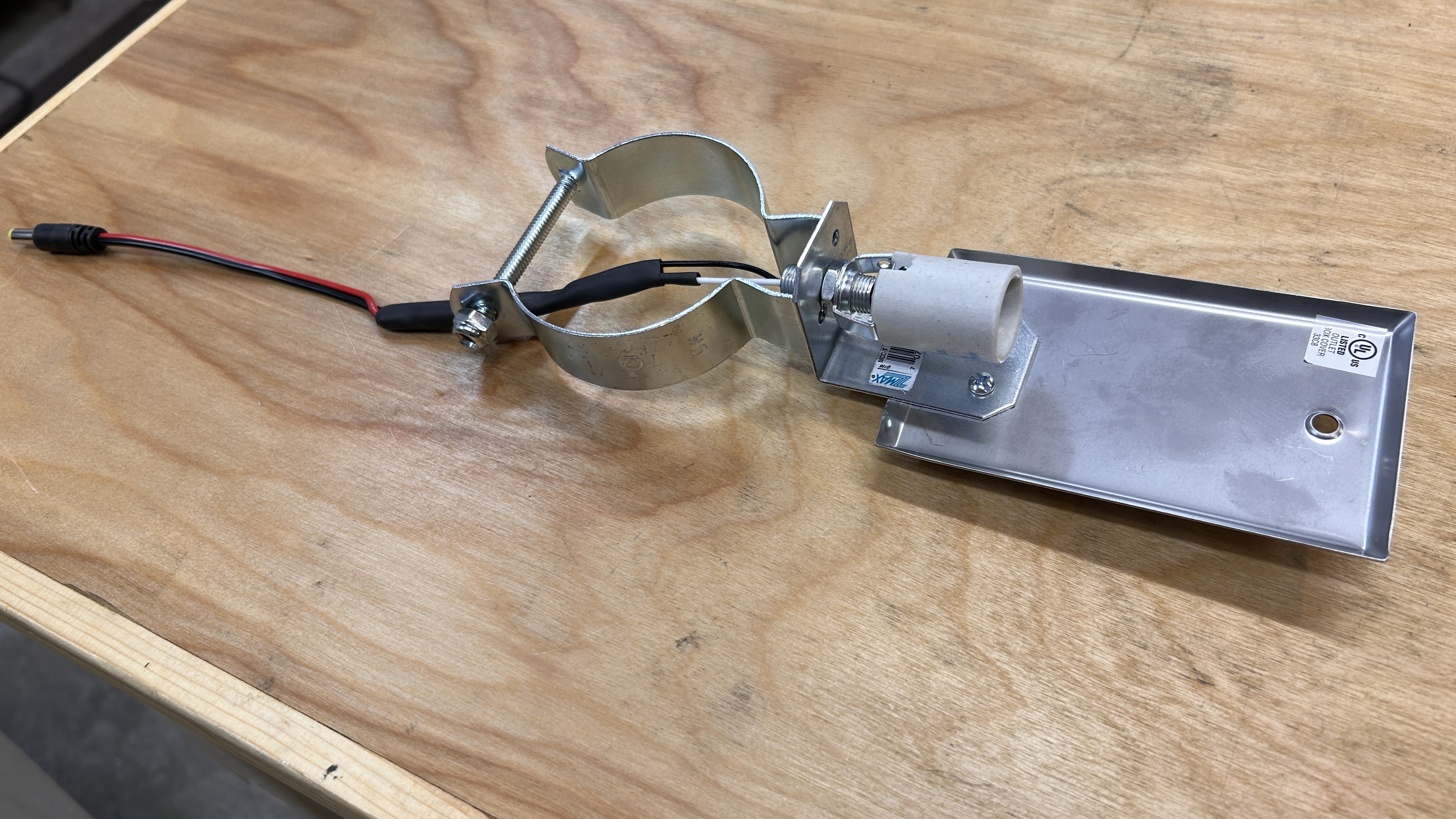

I built a light kit with some super cheap items from Lowe's. I think everything I bought from Lowe's came in under $10. Unfortunately, I had to buy packages of four bulb sockets and five bulbs from Amazon. Each socket was $2.37 and each bulb was $3.60, but my total layout was obviously more. Now I have plenty of spares ;-)

Here are the parts:

And here they are assembled:

The Conduit hangar clips around the column and holds the unit in place. The steel outlet blanking plate "shade" is totally optional, but I figured it will protect the bulb from sawdust and dirt falling on it, and it also keeps the light from shining upward through the head casting onto the ceiling (personal preference). Some people may like that effect ;-)

The only snag is that there wasn't enough room to get the carriage bolt into the conduit hangar "clamp" when it was in the head. I'll have to lift the head up almost all the way to the top to install it properly. For now, I ran a tie wrap through the bolt holes and tightened it down. It's a two person job to lift the head up and install the light kit properly.

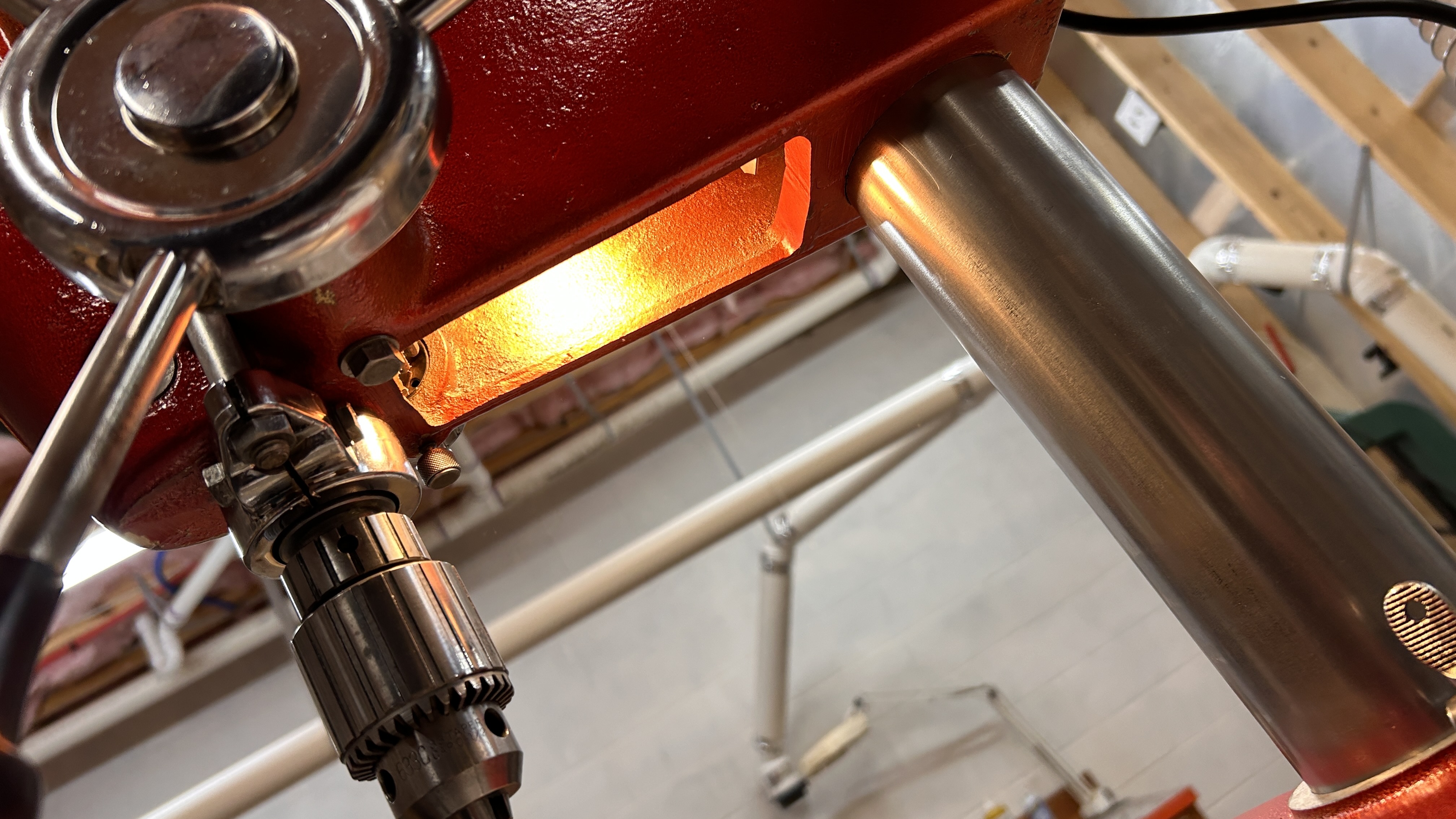

The kit mounted, looking down into the casting. It fits almost like it was built for that space..

The light is wired to the motor switch, so the light comes on whenever the motor is running. My spindle isn't turning in this photo because I'm waiting for my belts to come in.

The only thing left to do is to finish up the Vari-Slo drive. Once the belts come in, it will take no time at all. I made the mistake of thinking I could just pop into the auto parts store and pick up the belts today. Nope. I ordered them this morning and they'll be here in two days.

I built a light kit with some super cheap items from Lowe's. I think everything I bought from Lowe's came in under $10. Unfortunately, I had to buy packages of four bulb sockets and five bulbs from Amazon. Each socket was $2.37 and each bulb was $3.60, but my total layout was obviously more. Now I have plenty of spares ;-)

Here are the parts:

And here they are assembled:

The Conduit hangar clips around the column and holds the unit in place. The steel outlet blanking plate "shade" is totally optional, but I figured it will protect the bulb from sawdust and dirt falling on it, and it also keeps the light from shining upward through the head casting onto the ceiling (personal preference). Some people may like that effect ;-)

The only snag is that there wasn't enough room to get the carriage bolt into the conduit hangar "clamp" when it was in the head. I'll have to lift the head up almost all the way to the top to install it properly. For now, I ran a tie wrap through the bolt holes and tightened it down. It's a two person job to lift the head up and install the light kit properly.

The kit mounted, looking down into the casting. It fits almost like it was built for that space..

The light is wired to the motor switch, so the light comes on whenever the motor is running. My spindle isn't turning in this photo because I'm waiting for my belts to come in.

The only thing left to do is to finish up the Vari-Slo drive. Once the belts come in, it will take no time at all. I made the mistake of thinking I could just pop into the auto parts store and pick up the belts today. Nope. I ordered them this morning and they'll be here in two days.

Really nice work. Thanks for sharing

The Drill Press is Done

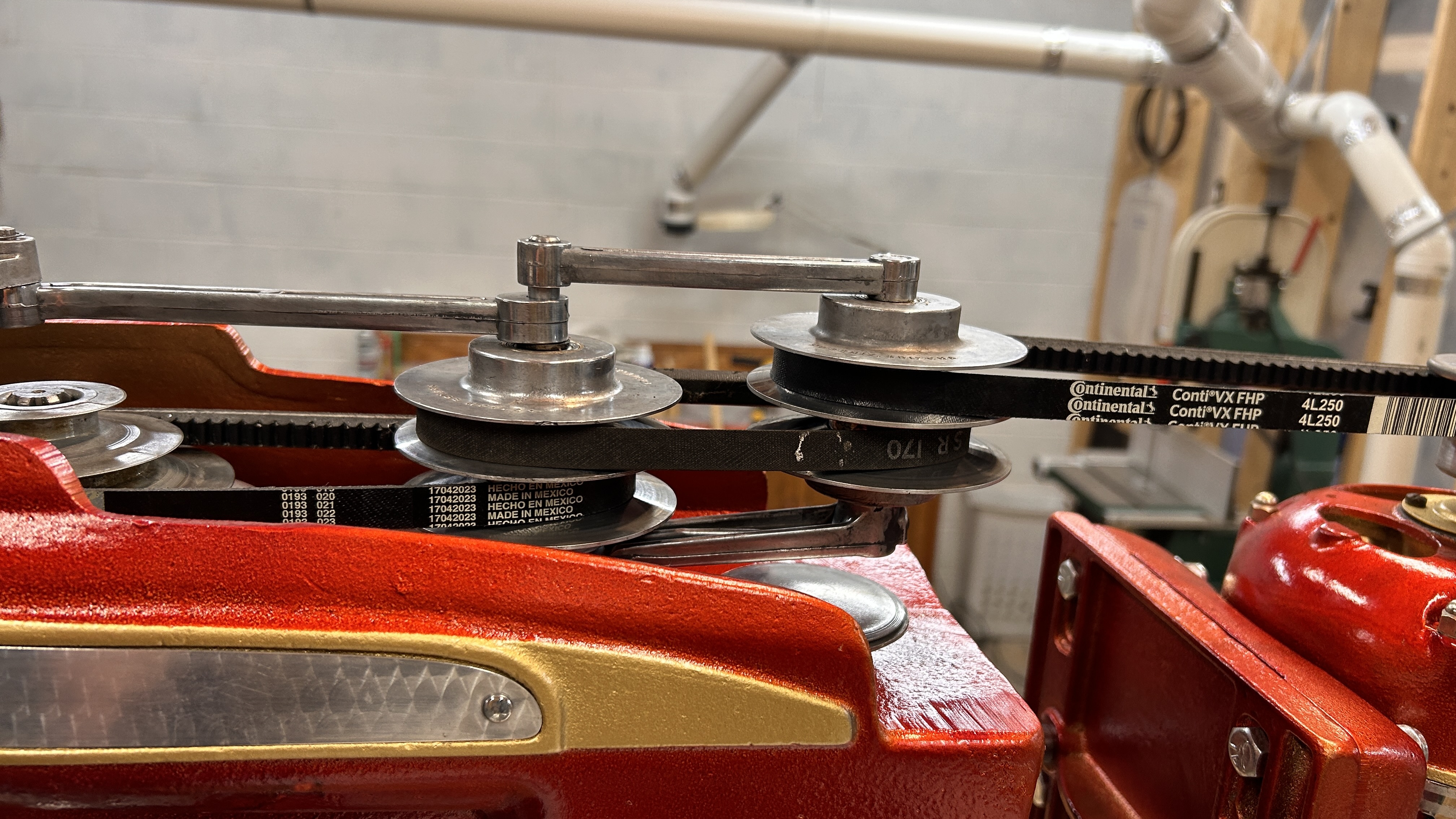

Since I needed to raise the head to install the Vari-Slo mechanism, I added the bolt to the light assembly to clamp it in place. One thing that scares me is if the head clamping lever is inadvertently loosened, the head will come down and all that force will damage the Vari-Slo system. The worm gear clamp at the top of the column will prevent the head from dropping as a result of a lapse in judgement.

I mentioned in a past post that I could not understand why the Vari-Slo pulleys were packed with grease. On an install guide, the document mentions the pulleys are packed with grease so you do not have to lubricate them. Well, I took another look and lo and behold, a tiny hole in the bore I missed.

So... I packed them with grease...

... and extruded a nice void-free hunk of grease when I installed the pulley.

Amazon came with the new belts today and just my luck, instead of a 17" belt, they sent me a 36" belt. I had to reuse the intermediate belt, but a new one will be here Thursday. Belt changes now only take a minute or two ;-)

Finally... here's a video of the drill press running before and after. (hope this works)

I'll post the "After" photos and video in the original post so people don't have to go through the entire thread to see the results.

This was a fun project. I didn't know what I was in for, but the drill press was much less complicated than I expected. The Vari-Slo... maybe not so much, though it wasn't so bad thanks to the great videos on YouTube.

Thanks to all for following along and your comments. Much appreciated!

Since I needed to raise the head to install the Vari-Slo mechanism, I added the bolt to the light assembly to clamp it in place. One thing that scares me is if the head clamping lever is inadvertently loosened, the head will come down and all that force will damage the Vari-Slo system. The worm gear clamp at the top of the column will prevent the head from dropping as a result of a lapse in judgement.

I mentioned in a past post that I could not understand why the Vari-Slo pulleys were packed with grease. On an install guide, the document mentions the pulleys are packed with grease so you do not have to lubricate them. Well, I took another look and lo and behold, a tiny hole in the bore I missed.

So... I packed them with grease...

... and extruded a nice void-free hunk of grease when I installed the pulley.

Amazon came with the new belts today and just my luck, instead of a 17" belt, they sent me a 36" belt. I had to reuse the intermediate belt, but a new one will be here Thursday. Belt changes now only take a minute or two ;-)

Finally... here's a video of the drill press running before and after. (hope this works)

I'll post the "After" photos and video in the original post so people don't have to go through the entire thread to see the results.

This was a fun project. I didn't know what I was in for, but the drill press was much less complicated than I expected. The Vari-Slo... maybe not so much, though it wasn't so bad thanks to the great videos on YouTube.

Thanks to all for following along and your comments. Much appreciated!

LATEST FOR SALE LISTINGS

-

-

-

SOLD -- $75: Gast moa v113 Vacuum Pump Veneer, 60" bag and board

- Started by peterdnight

- Replies: 1

-

GONE: Gladiator 5 cleats, 10 hangers, Paper Towel and Shelf

- Started by peterdnight

- Replies: 3

-

SOLD -- $100 Makita mac700 portable air + grex pin nailer + 2 others + 50' hose

- Started by peterdnight

- Replies: 1