You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

work in progress, 1/6th 1890's navy steam launch built to navy plans

- Thread starter tghsmith

- Start date

I made some longer strips of wood to use clothes pin springs when building model boats. They extend the reach vs regular clothes pins.most woodworkers has a wall of bar-clamps, I have a pile of small C-clamps

Tony

started the white cedar hull planking,, so much easier than white oak,, needs only a hot water soak and a little hot iron work and the curves are set,, things should speed up a bit.. have to start laying out the cradle for when the hull comes off the board!!!

Attachments

getting to the less twisty planks and starting the spiling(naut. term for shaping) of planks for proper fit.. , the Lee Valley 1/3 scale planes are working great for this shorter plane taking deeper cuts to get things roughed dowm,, long plane set fine to even the final line..

Attachments

still planking away,, but in planning for the time the hull comes off the board took a few minutes to make a work stand,, samples of scale screws arrived, they should work well, I ordered some more!!!

Attachments

so the last planks could be clamped (no long reach small C-clamps) it was declared "off the building board" day .. a friend, two heat guns had the hot glue giving up it's grip on things in a few minutes, set some metal items in place to get the look of things

Attachments

thanks all,, planking complete,, seams calks with epoxy paste,, lots of sanding,, given a good heavy coat of primer that will be mostly all sanded off.. coated the inside with epoxy resin with milled fibers added along with tinting to match the navy spec'ed lead gray color.. everything gets to set and cure for the weekend..

Attachments

Slim is back on quality control as the leveling of the frames inside has started,, this need to be precise as I plan to use the line where the decking meets the waterway as the point to make the deck removable.. exacto spokeshave is useless (LV scale spokeshave is in transit) the dremel right angle head is great for roughing things out then its homemade flex sander and sanding blocks..

Attachments

When I was on the USS Theodore Roosevelt in 1988, we visited the French port of Toulon. I was in an antique shop that had a number of vintage nautical items. One thing that caught my eye was a drawing of the bowsprit and figurehead portion of the bow for an 18th century French warship. It was done using the same artistic technique as this:

My guess was that it wasn't a shipwright's plan, but a rendering in a collection of drawings to be presented to the admiralty for approval for construction. There was some added notation in French in the margins in impossibly elegant handwriting. Imagine something like this but much more detailed and ornate as above:

Including the border it was about 45"x30" and priced at about $175 which seemed like a lot of money to me at the time. I pondered for a while and even did another lap around the store looking at other items before returning to it, but ultimately walked out without it.

I don't have too many regrets about things I didn't buy, but that is one of them.

I almost drove back 90 miles for a belt buckle I passed on in AZ.. (still wish I had gone back) A woodsmith/boatbuilder selected me a great piece of hackmatack for the project,, re-saw fence on the bandsaw to slice it up,, put on a very narrow blade to rough out the knees and corners.. (faster and cleaner than the scroll saw) clamp boards have been formed and set in place,, marked out for knees, timbers and beams,, wood for the bilge boards have been prepped,, the LV scale spokeshave arrived,, looks and works great.. used some number stamps as small branding irons to mark select frame numbers on the keel...

Attachments

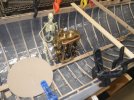

mounting up brass fittings and making mountings,, engine mounting beams installed, rudder fittings installed, cut-water installed,, most of the floor beams installed,, its been a good week.. told slim all he had to do over the weekend was watch the epoxy cure..

Attachments

more progress,, frames leveled for mounting the boiler support keelsons,, blocks added where pipes for the keel mounted condenser will pass through,, clamp boards and main cross beams mounted,, the clamp boards removed any gunnel flex the hull had.. I may be on the lookout for a long piece of air dried cherry 1 x 2 x 36 to bend and form the cap molding ..

Attachments

LATEST FOR SALE LISTINGS

-

-

-

FS: Reliance Electric J.R. Reeves Drive 415-107-45-AG

- Started by Rick_B

- Replies: 0

-

For Sale For Sale: Festool HKS 55 EB carpentry saw + FSK track ($450)

- Started by jamie

- Replies: 0

-