You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tung vs teak vs lemon vs linseed oil

- Status

- Not open for further replies.

The holy wars often begin after this question is asked. For starters, "teak oil" is a blend of varnish and oils. Lemon oil is a cleaning product. Here is something about that:

http://www.antiqueweb.com/articles/antique_furniture_oil_wax.html

Tung oil and linseed oil are drying oils in their pure forms, that dry slowly, so a lot of things that have linseed or tung in the name are mixtures, which usually contain some of the oil. They both impart a little amber coloring, tung more than linseed. IME, tung dries harder and provides the better finish as far as pure oils go.

Russ Fairfield, turner extraordinaire, is an expert with an opinion similar to mine:

http://www.antiqueweb.com/articles/antique_furniture_oil_wax.html

Tung oil and linseed oil are drying oils in their pure forms, that dry slowly, so a lot of things that have linseed or tung in the name are mixtures, which usually contain some of the oil. They both impart a little amber coloring, tung more than linseed. IME, tung dries harder and provides the better finish as far as pure oils go.

Russ Fairfield, turner extraordinaire, is an expert with an opinion similar to mine:

source: http://www.woodcentral.com/russ/finish6.shtmlPure Tung Oil provides a hard and tough surface finish that is absolutely waterproof; impervious to dust, alcohol, acetone, fruit and vegetable acids; and it doesn't darken with age like Linseed and other vegetable oils.

Thanks, that helps clear it up. I'm not really looking for a finish, but something to revitalize and protect the wood...I have a rosewood fingerboard as well as a table that could use it.

The only one I have used is lemon oil. I read in a sailing book that it would kill mold. We used it on wood that got moldy inside the boat and it worked wonderfully and eliminated the smell.

The only one I have used is lemon oil. I read in a sailing book that it would kill mold. We used it on wood that got moldy inside the boat and it worked wonderfully and eliminated the smell.

Thanks, that helps clear it up. I'm not really looking for a finish, but something to revitalize and protect the wood...I have a rosewood fingerboard as well as a table that could use it.

The only one I have used is lemon oil. I read in a sailing book that it would kill mold. We used it on wood that got moldy inside the boat and it worked wonderfully and eliminated the smell.

Temporarily... Andy got it right. If you're trying to revitalize wood, first you need to clean it up. Then use paste wax. Anything else is temporary (so is paste wax, but at least it's a solvent for itself!). Everything needs care -- how often depends on how oftien it's used. A fingerboard that sits unplayed isn't a challenge. A table that gets used every day is a major challenge.

To clean, I'd try simple mineral spirits first and see if it works. Then wax. If it needs serious cleaning you may need saddle soap or something similar. Wax as soon as it's completely dry.

BTW, most spray "waxes", lemon oils, etc. are solvents for wax and won't help you long term -- just provide maybe a nice aroma and short term gleam. Clean them off, wax with a good paste wax and maintain it properly. If you really are serious about maintaining wood finishes, read Bob Flexner's book. Rich

>>>>> Pure Tung Oil provides a hard and tough surface finish that is absolutely waterproof; impervious to dust, alcohol, acetone, fruit and vegetable acids; and it doesn't darken with age like Linseed and other vegetable oils.

I have to take exception to the above. Pure tung oil does not dry hard. It dries sort of semi-soft. It not a "surface" finish: It is an oil that penetrates the surface and because it is soft, it provides no abrasion or resistance to abuse. It is soft, therefore, it is not "tough". It is not "waterproof". It is somewhat more water resistant than linseed oil but only if built up using a large number of applications. I have no idea what "impervious to dust" means. Dust will very easily come to rest on a tung oil coated surface. Alcohol and acetone will very easily damage tung oil.

In general, pure tung oil is a very poor finish with little or no protective qualities. It's best reserved as a colorant to "pop" the figure in wood. But, linseed oil does a better job at this than tung oil.

Now there are a number of finishes labeled "tung oil finish". These are an entirely different animal. These products are a mixture of linseed oil and varnish. Almost none of the so called "tung oil finishes" contain any true tung oil at all. But, because they contain a varnish, they are a much better protective and durable product that can fairly mimic an oil finish.

I have to take exception to the above. Pure tung oil does not dry hard. It dries sort of semi-soft. It not a "surface" finish: It is an oil that penetrates the surface and because it is soft, it provides no abrasion or resistance to abuse. It is soft, therefore, it is not "tough". It is not "waterproof". It is somewhat more water resistant than linseed oil but only if built up using a large number of applications. I have no idea what "impervious to dust" means. Dust will very easily come to rest on a tung oil coated surface. Alcohol and acetone will very easily damage tung oil.

In general, pure tung oil is a very poor finish with little or no protective qualities. It's best reserved as a colorant to "pop" the figure in wood. But, linseed oil does a better job at this than tung oil.

Now there are a number of finishes labeled "tung oil finish". These are an entirely different animal. These products are a mixture of linseed oil and varnish. Almost none of the so called "tung oil finishes" contain any true tung oil at all. But, because they contain a varnish, they are a much better protective and durable product that can fairly mimic an oil finish.

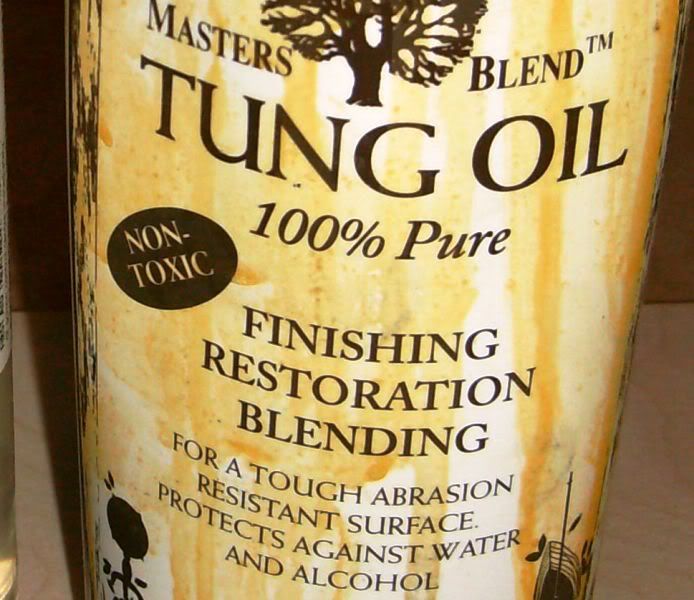

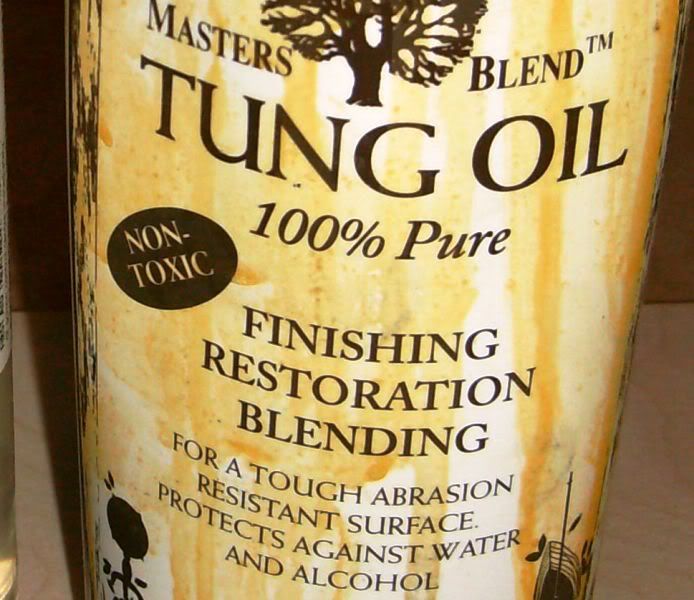

Here is the product description of Master's Blend, which I have years of first hand experience with:

I have used it on boat rails and furniture that lived outdoors. The only time I have regretted using it was on treenware, because it does add some unwanted taste to food when it isn't well cured. There are some inferior products out there that claim to be tung oil; I can only assume that some opinions are based on that. I base mine on first hand experiences.Finishing a job correctly makes your craftsmanship truly shine. This tung oil is non toxic and produces a tough hard surface which is absolutely waterproof, and abrasion resistant. Penetrates wood fibers enhancing both grain and color.

Here is the product description of Master's Blend, which I have years of first hand experience with:

I have used it on boat rails and furniture that lived outdoors. The only time I have regretted using it was on treenware, because it does add some unwanted taste to food when it isn't well cured. There are some inferior products out there that claim to be tung oil; I can only assume that some opinions are based on that. I base mine on first hand experiences.

I agree completely with Howard -- I've used pure tung oil as well as custom mixes of tung oil and polyurethane for the past six years. While I've found the finish (with 6 - 7 coats) to be strong and "hard", the application is for carvings which are looked at rather than furniture which is heavily used (like tables). Be aware that tung oil has one particular nasty trait which is that it may cure and leave a white deposit in cracks and crevices -- not nice to discover weeks or months later.

Andy, the name "Master's Blend" suggests that it is not pure tung oil. While I can't speak for that product, I have used other "tung oil" products in the past -- particularly on my dining room table. All I can say is that I found them difficult to use and will never try one of these again. In particular, the last one I used a number of years ago was not only difficult, but in no way lived up to the claims of "hard", "heat proof" and "waterproof". My wife rather foolishly left a pot that she assumed to be "leak proof" sitting on then recently refinished table. The resulting water seep caused a 4 inch black ring to develop in the oak under the finish. After some testing with my own custom oil/poly mix, I'm currently in the process of a MUCH REQUESTED refinishing of the table. (A black ring is almost impossible to remove as it is actually IN the wood. I found that a paste of Barkeeper's Freind" -- primary ingredient, oxalic acid -- transformed the ring into a perfect match for the dark tones of the oak while not changing the basic oak coloring at all. The ring is still there, it's just a lot more pleasing. :icon_cheers )

Notice I referred to "testing". If you plan to do a lot of finishing and want to know about different finishes, I would encourage you to make a sample strip of different kinds of wood (I used black walnut, maple, red oak, and cherry) with different sections of the strip finished using similar techniques, but different finishes or combinations of finishes. That way you can compare the results and have a long term record (write everything down -- you won't remember in a few years). My strips were done 4 or 5 years ago and are now hanging on the wall of my finish room. I last refered to them two weeks ago before starting the table refinish. I also have a small piece of red oak that I finished in the way I planned to do the table. For the past year, my wife and I have used it as a spoon rest while cooking. So far nothing has affected it in any way.

If you are interested or have a need to refinish (whether antiques or just prized furniture), I heartily recommend an old book (1989) by Bruce Johnson, "The Weekend Refinisher" (it's possible it may be availalbe in a newer edition). I like the older book because it assumes practical materials rather than the "latest" invention on Lowe's shelves.

Edit: I should also have said that while tung oil is one of my finishes, I more commonly use linseed oil and also combinations of shellac, oils and polyurethane depending on the need.

Rich

Rich,

Master's Blend is a brand, but this is not a mix:

Yeah, I am a little sloppy...

I do mix it, usually 1:1 with terps or spirits. I would not recommend it to be used without mixing. I have used it on several different woods. On outdoor stuff, I have come to prefer an oil finish because I have a history of letting it go a little too long before reapplying. I used spar varnish on some projects and if you let it go too long it cracks and peels. You have to remove it to refinish. With oil, you just have to get the wood clean and dry and apply more coats. Besides the boat rails and outdoor furniture, I have also used it on seasonal decorations that live in the hot attic most of the year and then go out in the weather a few weeks, and toys and what not for the kids.

If something gets left on the ground for a while, it will mildew. It does have an amber color and it does taste bad (DAMHIKT ). But it is very safe and easy to use.

). But it is very safe and easy to use.

I think the things that claim to be tung but are not have given some people a different impression. People are really polarized on this issue; love it or hate it. And there are respected experts on both sides.

Here are some additional resources:

http://www.house-painting-info.com/tung-oil.html

http://www.doityourself.com/stry/wftungoil

http://www.sutherlandwelles.com/tungoil.htm

Master's Blend is a brand, but this is not a mix:

Yeah, I am a little sloppy...

I do mix it, usually 1:1 with terps or spirits. I would not recommend it to be used without mixing. I have used it on several different woods. On outdoor stuff, I have come to prefer an oil finish because I have a history of letting it go a little too long before reapplying. I used spar varnish on some projects and if you let it go too long it cracks and peels. You have to remove it to refinish. With oil, you just have to get the wood clean and dry and apply more coats. Besides the boat rails and outdoor furniture, I have also used it on seasonal decorations that live in the hot attic most of the year and then go out in the weather a few weeks, and toys and what not for the kids.

If something gets left on the ground for a while, it will mildew. It does have an amber color and it does taste bad (DAMHIKT

I think the things that claim to be tung but are not have given some people a different impression. People are really polarized on this issue; love it or hate it. And there are respected experts on both sides.

Here are some additional resources:

http://www.house-painting-info.com/tung-oil.html

http://www.doityourself.com/stry/wftungoil

http://www.sutherlandwelles.com/tungoil.htm

Here's a link by Bob Flexner that you might find helpful.

http://www.popularwoodworking.com/features/finish2.html

http://www.popularwoodworking.com/features/finish2.html

Here's a link by Bob Flexner that you might find helpful.

http://www.popularwoodworking.com/features/finish2.html

Thanks for that. He has an interesting take on it:

The extra work he refers to is sanding:Only if you are willing to go through the extra work for the increased water resistance you get in a non-building finish should you use real tung oil.

This oil, which is pressed from the nuts of a tung tree, was introduced to the West from China about 1900. It was useful for making superior, water-resistant varnishes, especially for outdoor use.

But tung oil is too difficult for most people to use by itself as a finish. You apply tung oil just like linseed oil or oil/varnish blend, but you have to sand tung oil after every coat, not just after the first, and it takes five to seven coats, allowing two to three days drying time between each, to achieve a smooth, attractive sheen.

I don't sand between every coat, but then I don't do fine furniture. :dontknow:

Below is another little snippet from a vendor that might shed light on differing opinions also:

they go on to claim they only use the finest, yada yada yada, but the point is that it is not a simple compound that is either pure or not; there can be wide variances in quality even if no processing is done.All Pure Tung Oils are not the same. Some low priced marketers will package South American Tung Oil (dark, greenish in color) and sell its as the higher quality Chinese Tung Oils. Chinese Pure Tung Oil is available in 3 grades

I obviously drank the cool aid and joined the cult of tung oil believers, but not blindly...

- Status

- Not open for further replies.