I'm new to this website, so I apologize in advance if my thread-posting etiquette is poor.

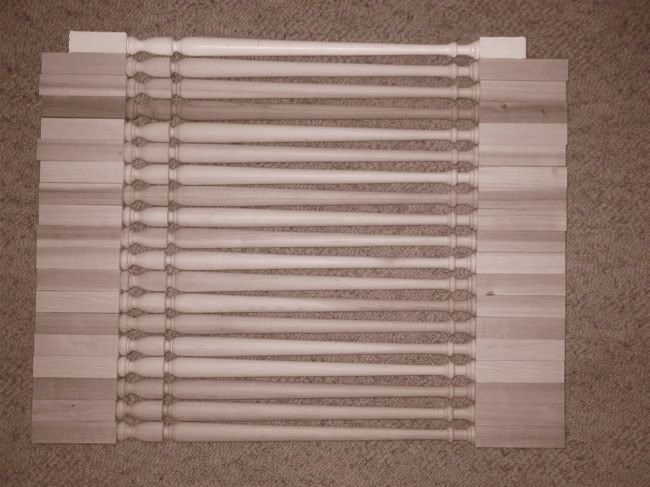

Here's my quandary ... should I buy a lathe solely to equip it with a duplicator strictly to make legs and spindles for my furniture-making [desks, tables, cabinets, beds, shelves, interior/exterior doors, planters, Adirondack-type chairs] ?

Being "anal retentive", everything's been square/tapered, well-trimmed out, or parts sculpted with a bandsaw and spindle sander and then duplicated on the table router. Gets kinda boring after 40+ years.

Having too much money and too much space, I've been itching to add either [a] a 5 HP shaper and/or a 36-42" lathe equipped with a Vega duplicator [my understanding is that I'd be able to go up to 4"x4" blanks with this set up]. Ten years from the urn, I have NO interest in becoming a "turner", no interest in making pens and bowls; and I make plenty of sawdust now.

I have two projects in the queue for the Fall which could possibly use the turnings: table for the foyer and queen bed.

So, take the plunge or stick with what I do best? What woods turn best with a duplicator [I keep cypress, cherry, maple, walnut, red and white oak, ash, sweet gum, poplar, and some pear on hand at all times]. Another question ... where can I buy templates or PDF files from which to make templates for these parts?

Thanks

Here's my quandary ... should I buy a lathe solely to equip it with a duplicator strictly to make legs and spindles for my furniture-making [desks, tables, cabinets, beds, shelves, interior/exterior doors, planters, Adirondack-type chairs] ?

Being "anal retentive", everything's been square/tapered, well-trimmed out, or parts sculpted with a bandsaw and spindle sander and then duplicated on the table router. Gets kinda boring after 40+ years.

Having too much money and too much space, I've been itching to add either [a] a 5 HP shaper and/or a 36-42" lathe equipped with a Vega duplicator [my understanding is that I'd be able to go up to 4"x4" blanks with this set up]. Ten years from the urn, I have NO interest in becoming a "turner", no interest in making pens and bowls; and I make plenty of sawdust now.

I have two projects in the queue for the Fall which could possibly use the turnings: table for the foyer and queen bed.

So, take the plunge or stick with what I do best? What woods turn best with a duplicator [I keep cypress, cherry, maple, walnut, red and white oak, ash, sweet gum, poplar, and some pear on hand at all times]. Another question ... where can I buy templates or PDF files from which to make templates for these parts?

Thanks