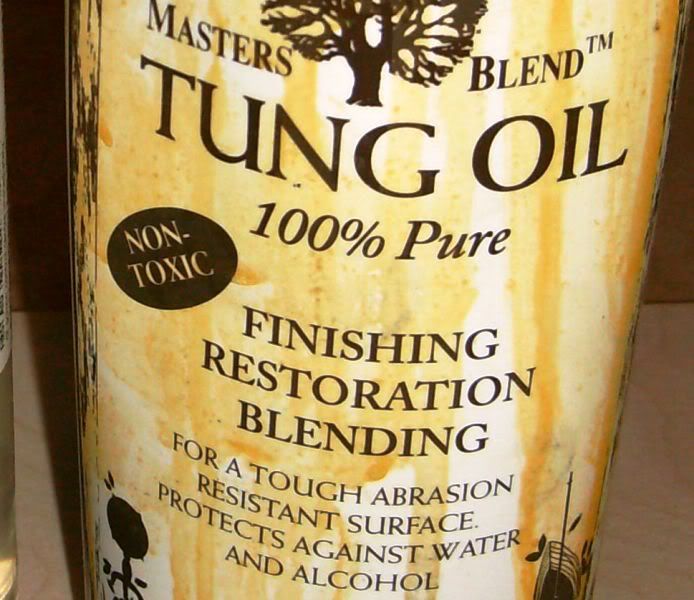

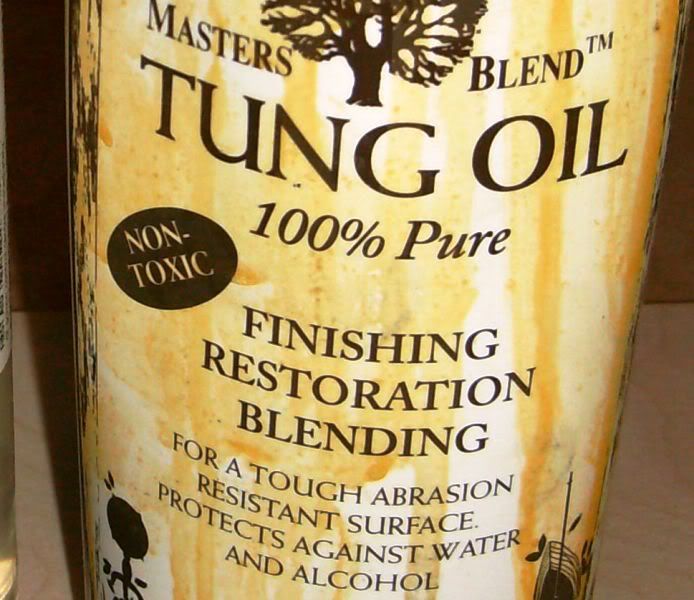

My last post debating the quality of tung oil; I won't beat the horse any further, but I found the data Howard refers to and I am providing a link and my opinion of why it fared poorly when applied improperly.

My data comes from the US Forest Service Wood Products Lab Wood Handbook which classifies pure tung oil and linseed oil as providing no water or water vapor resistance. While pure tung oil is slightly more water resistant than linseed oil, neither have any real protective qualities.

That information is available online:

http://www.fpl.fs.fed.us/documnts/fplgtr/fplgtr113/ch15.pdf

The chart is on page 12. Tung oil didn't fare well in their test, but I am not surprised when you look closely. They tested 1, 2 and 3 coats and then checked them after 1 day, 7 days and 14 days. I am inferring that they put all 3 coats on the same day, but I could be wrong. I use more like 6 or 8 and don't apply them all in one day. My boat's brightwork has more like 10 or 12 and will get another coat or two in the spring. If you look at any datasheet on applying tung oil, like this one:

http://www.thewoodworks.com.au/site/datasheets/tungoil.html

you will find instructions like this:

Apply an initial wash coat, wipe off after a few minutes when the oil begins to tack and complete the process over several days with several light coats.

So the value of a test using 3 coats in one day is questionable at best, IMO. I don't know why they didn't follow the instructions; they did up to 6 coats for several other finishes.

A counterpoint from another recognizable name:

Pure Tung Oil provides a hard and tough surface finish that is absolutely waterproof; impervious to dust, alcohol, acetone, fruit and vegetable acids; and it doesn't darken with age like Linseed and other vegetable oils. - Russ Fairfield

http://www.woodcentral.com/russ/finish6.shtml

Tung oil is absolutely a pain to use if you are in a hurry and you won't get high gloss that will stay glossy. But saying it isn't a good finish and isn't water repellent is categorically incorrect, IMO.

OK, I'm done; we will now resume our regular programming...