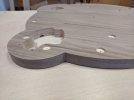

"Thick" probably isn't the best way to describe it, but I've had on my 'todo' list for a while to build a console table like this. https://www.arhaus.com/products/sullivan-console-table.

Anyone built something like this and have any pointers? The description of the item itself mentions the use of veneers. The only thing I've ever used veneers for is edge banding! So, to get started, I'd appreciate any advise or input on the structure of such an item that would be veneered and any other input I should be thinking about while this is still in the concept phase!

many thanks

Anyone built something like this and have any pointers? The description of the item itself mentions the use of veneers. The only thing I've ever used veneers for is edge banding! So, to get started, I'd appreciate any advise or input on the structure of such an item that would be veneered and any other input I should be thinking about while this is still in the concept phase!

many thanks