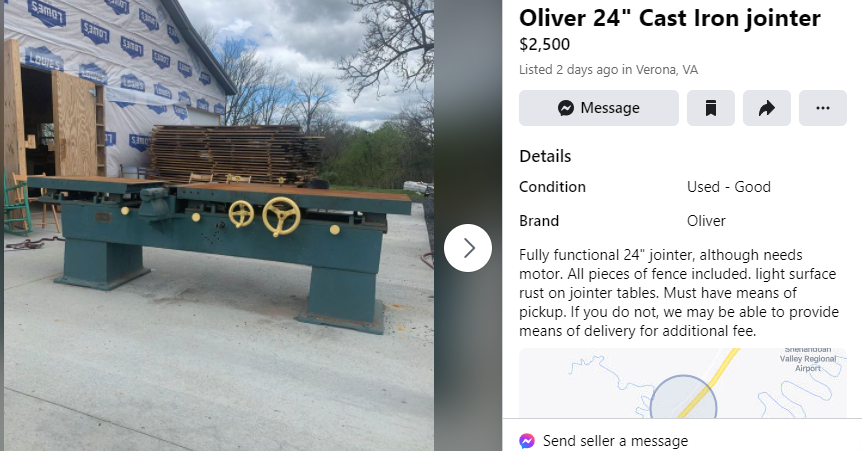

Found this trolling on Facebook: TWENTY FOUR INCH JOINTER!!!!

Facebook

www.facebook.com

"Fully functional 24" jointer, although needs motor. All pieces of fence included. light surface rust on jointer tables."

www.facebook.com

"Fully functional 24" jointer, although needs motor. All pieces of fence included. light surface rust on jointer tables."

(Fully functional, but it needs a motor! LOL)

I posted some pictures for those who don't do facebook, so you could still enjoy!

www.facebook.com

www.facebook.com

(Fully functional, but it needs a motor! LOL)

I posted some pictures for those who don't do facebook, so you could still enjoy!