After I got the crib built back in July, the wife started in on wanting a changing table. Personally I don't see what's wrong with using the folding table we have now but SWMBO wants one bad, so I guess there is no alternative.

I am building the table in a design to mirror the crib and it's gonna end up being pretty much a set of book shelves.

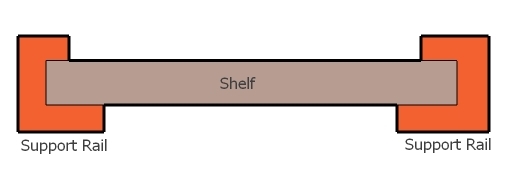

I saw a sofa/window table someone built a while back and they ran the shelves with the grain perpendicular to the length of the shelf. Kind of opposite the normal direction. I really liked the look of this, not to mention it's different.

I am wondering if running the grain this way will provide too much wood movement or is there someway to allow for this movement? I'm using white oak if that helps with the amount of space needed for proper movement.

WOW, that's long winded...I'm off to bed, hopefully tomorrow I'll have some WIP pics to share.

TIA!

I am building the table in a design to mirror the crib and it's gonna end up being pretty much a set of book shelves.

I saw a sofa/window table someone built a while back and they ran the shelves with the grain perpendicular to the length of the shelf. Kind of opposite the normal direction. I really liked the look of this, not to mention it's different.

I am wondering if running the grain this way will provide too much wood movement or is there someway to allow for this movement? I'm using white oak if that helps with the amount of space needed for proper movement.

WOW, that's long winded...I'm off to bed, hopefully tomorrow I'll have some WIP pics to share.

TIA!