I recently purchased the four diamond plates from DMT that I mentioned in a previous thread. One of the challenges is to keep these in place while in use. The underside is smooth. After applying lubricant they can easily slide about as you push against them. There are various stands you can purchase. However, I decided to see what I had lying around the shop that I might use to make a base.

I'm constantly saving things that might otherwise be trash. Sometimes it becomes clutter and other times it pays off. This is one of those very satisfying times when I was able to take "trash" and turn it into something I can really use. Feels like double coupon day when that happens.

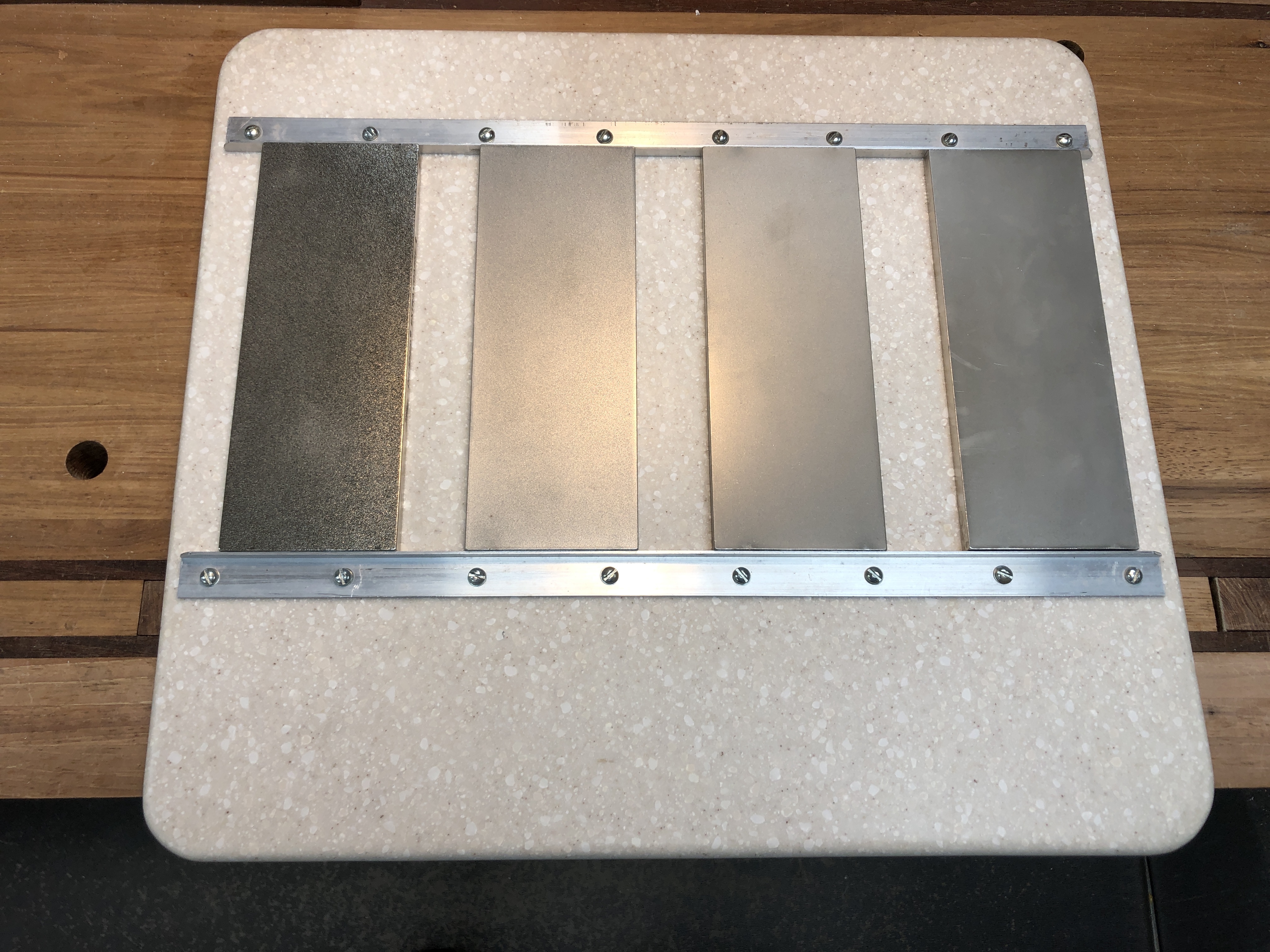

The base is made from an old sink cutout of solid surface material. The installers left us this from our kitchen countertops as a cutting board, but we've never used it as such. I cut two pieces of aluminum angle, then drilled and tapped holes to screw these in place. They are 8" apart -- the length of the sharpening plates. I did rip one side of the aluminum on my table saw so it is below the plates' surface. To keep the base in place as I work I added some rubber feet that I had in my parts cabinet.

A project complete, and no trip to the hardware store! BTW, the pictures show it on my workbench, but I don't sharpen tools there. I don't want to get the bench top wet, nor do I want filings where I do most of my woodwork. I have a separate space I use when sharpening.

I'm constantly saving things that might otherwise be trash. Sometimes it becomes clutter and other times it pays off. This is one of those very satisfying times when I was able to take "trash" and turn it into something I can really use. Feels like double coupon day when that happens.

The base is made from an old sink cutout of solid surface material. The installers left us this from our kitchen countertops as a cutting board, but we've never used it as such. I cut two pieces of aluminum angle, then drilled and tapped holes to screw these in place. They are 8" apart -- the length of the sharpening plates. I did rip one side of the aluminum on my table saw so it is below the plates' surface. To keep the base in place as I work I added some rubber feet that I had in my parts cabinet.

A project complete, and no trip to the hardware store! BTW, the pictures show it on my workbench, but I don't sharpen tools there. I don't want to get the bench top wet, nor do I want filings where I do most of my woodwork. I have a separate space I use when sharpening.