Earlier this year, I purchased a Ryobi BS904 9" bandsaw with the intent of converting it to a scrolling saw and selling my scroll saw to make room for it in my small shop. It came with a 1/4" blade.

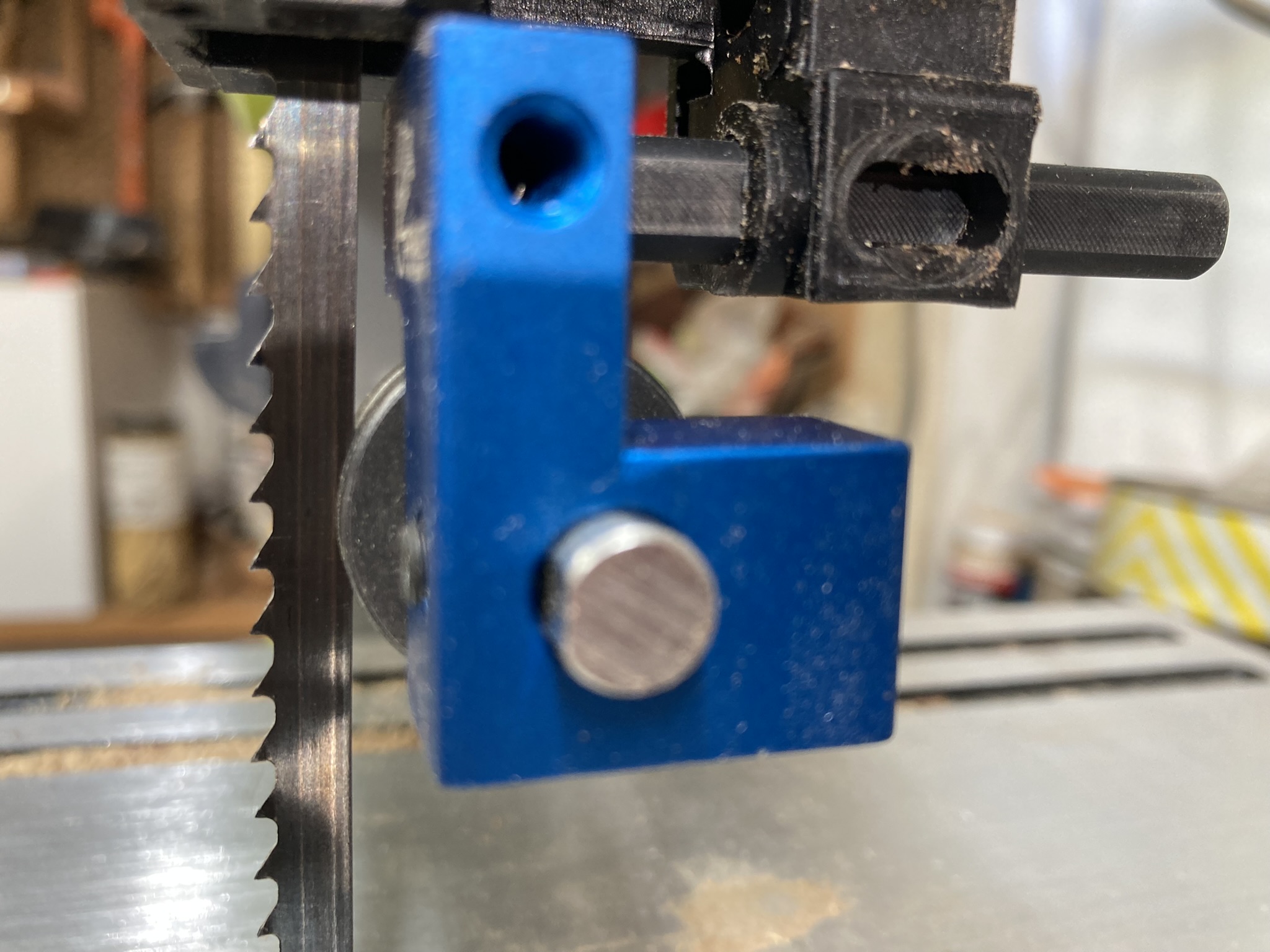

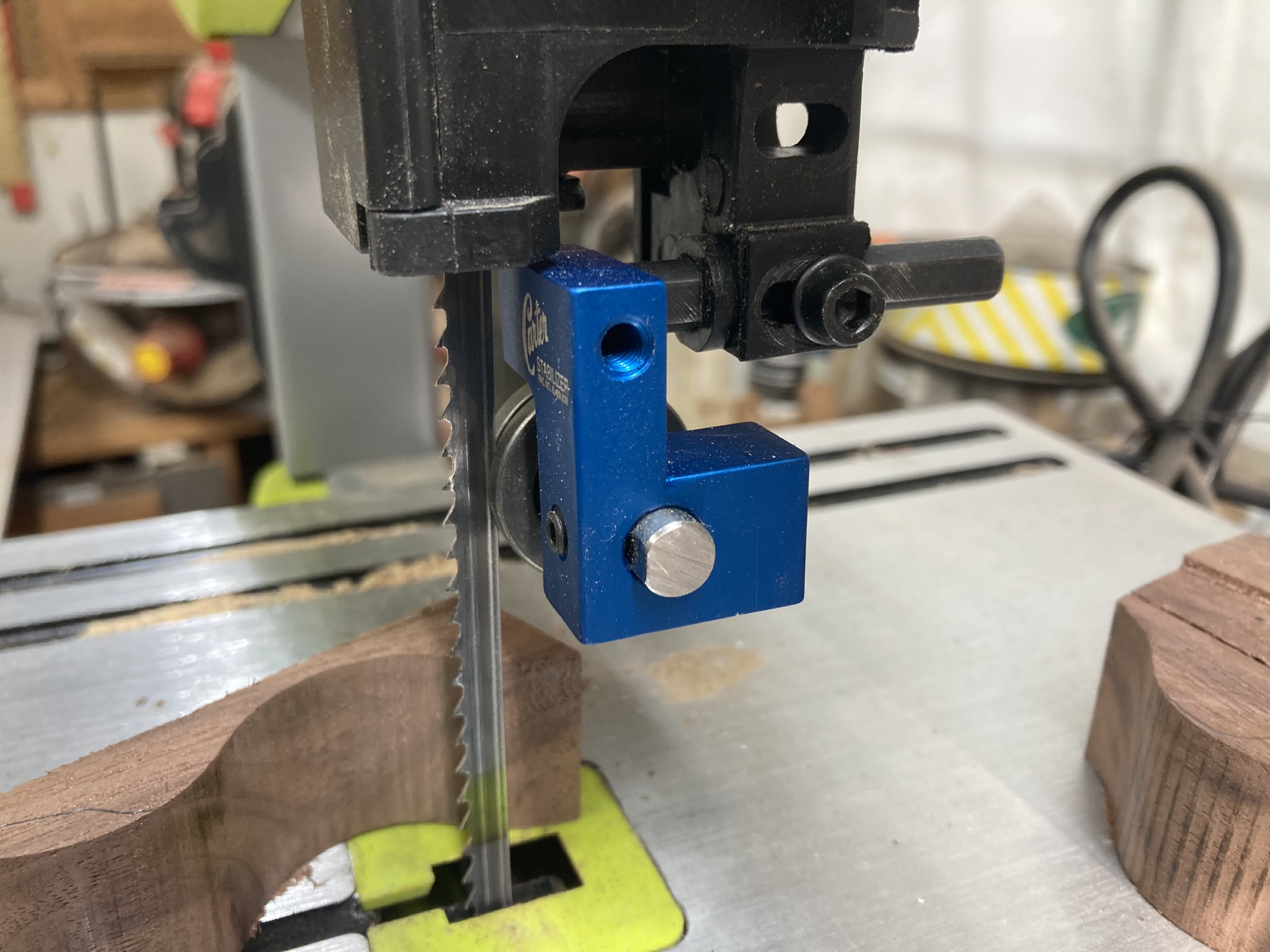

Recently I ordered a RYO1 Stabilizer from Carter Products and it installed like this. The Carter stud was a tight fit into the plastic Ryobi bracket but it looks like a tapped hole for a screw was missing.

I contacted Carter and got a prompt response that explained Ryobi had recently changed from a metal bracket with a threaded hole to a plastic bracket with a through hole and the RYO1 would not work. My options were to return the part or tap a hole myself. I chose to tap an M5-0.080 hole in the RYO1 stud since there is no alternative to the Carter stabilizer that I know of.

.

Now the RYO1 stud is secure in the D hole in the Ryobi bracket using the original screw. The threaded hole location in the stud was biased toward the back since the stud will move forward when I replace the 1/4" blade with an 1/8" blade soon.

Recently I ordered a RYO1 Stabilizer from Carter Products and it installed like this. The Carter stud was a tight fit into the plastic Ryobi bracket but it looks like a tapped hole for a screw was missing.

I contacted Carter and got a prompt response that explained Ryobi had recently changed from a metal bracket with a threaded hole to a plastic bracket with a through hole and the RYO1 would not work. My options were to return the part or tap a hole myself. I chose to tap an M5-0.080 hole in the RYO1 stud since there is no alternative to the Carter stabilizer that I know of.

.

Now the RYO1 stud is secure in the D hole in the Ryobi bracket using the original screw. The threaded hole location in the stud was biased toward the back since the stud will move forward when I replace the 1/4" blade with an 1/8" blade soon.