I am making a work bench which will have diagonal bracing in the back and the diagonals will have slots routed in them where they intersect to make them flush. Rather than making a guide for this specific project I want to make an adjustable one so it can be use in a variety of projects where slots are involved, i.e., it should able to guide the router so it can cut slots of differing angles, widths and lengths encountered in different projects. Before I begin, I thought I would ask if others have done this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Router guide ideas

- Thread starter kelLOGg

- Start date

I've only made lap joints on the table saw, but I've never tried an angle other than 90 degrees.

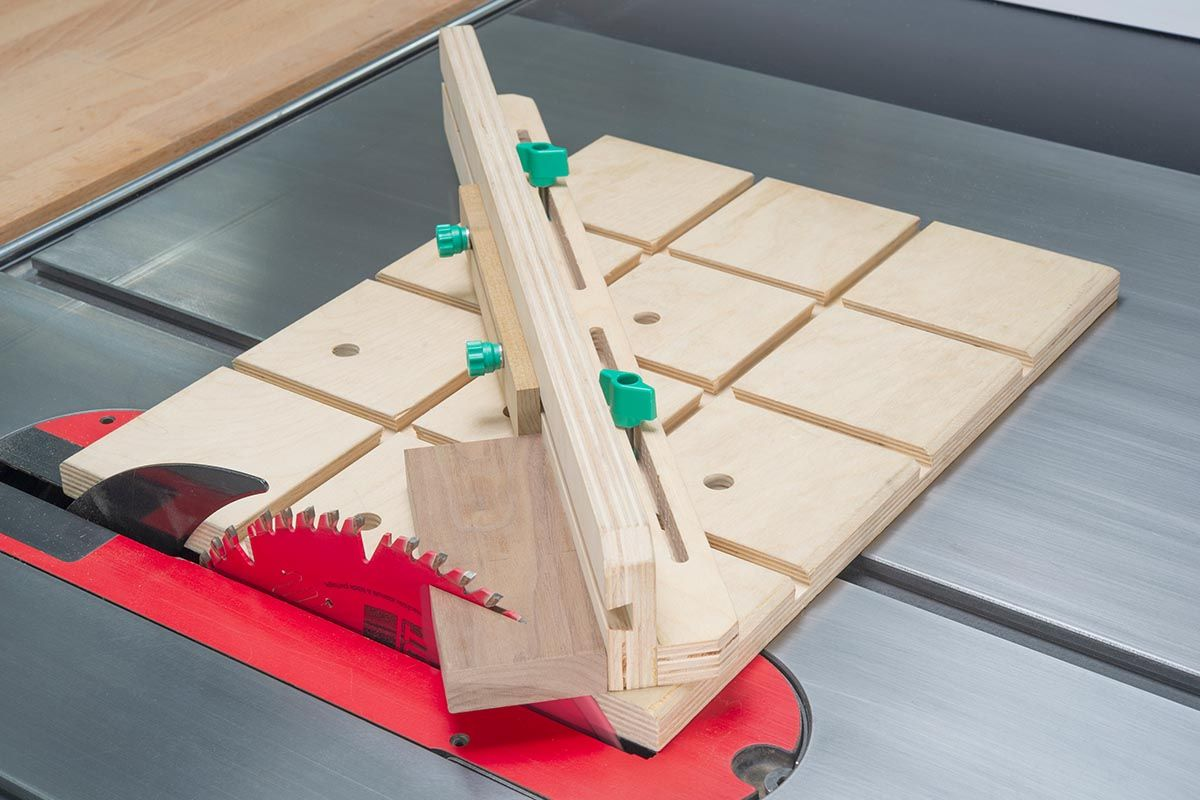

I think a sled like these could allow you to cut lap joints at a variety of angles.

Once you set the angle you could make a number of passes to creep up on the needed width.

I think a sled like these could allow you to cut lap joints at a variety of angles.

Once you set the angle you could make a number of passes to creep up on the needed width.

Bob:

One thing that you could try, if you have a dado set for your table saw, is to shim the dado set until it is the thickness of your brace material. You could create a sacrificial blade insert for your table saw, and run the dado set up through it to slightly more than half of your brace height. Lock the height in place and screw a sacrificial fence to your miter gauge, set the angle that your braces will intersect at, and cut the grooves in both pieces. You could make spacer blocks to accomodate the spacing on the braces, but pencil lines will probably work better in this instance, and allow you to align the marks with the dado before making the cuts.

Sorry, no pictures. Hope this helps.

Tone

One thing that you could try, if you have a dado set for your table saw, is to shim the dado set until it is the thickness of your brace material. You could create a sacrificial blade insert for your table saw, and run the dado set up through it to slightly more than half of your brace height. Lock the height in place and screw a sacrificial fence to your miter gauge, set the angle that your braces will intersect at, and cut the grooves in both pieces. You could make spacer blocks to accomodate the spacing on the braces, but pencil lines will probably work better in this instance, and allow you to align the marks with the dado before making the cuts.

Sorry, no pictures. Hope this helps.

Tone

Thanks for the replies, but I'm trying to steer clear of using a table saw for 2 reasons; 1) the diagonals I want to slot are 8+ ft long and my shop is too crowded for that, and 2) I'll be moving to a retirement home (too) soon and there's no space for a table saw. The workbench I am building will actually be built at the new residence. I am trying to cut some of the material first to make the transition to the new shop faster. Bench will go in the garage and will be 2' deep and 16' long.

Like pop-pop said this is where hand saws and careful layout prevails. In many cases by the time you workout the setup for your power tools you can actually have the job complete with hand tools. So really you may want to give it some thought.

In that case I'd use a track saw. You could cut both boards at once and tidy up the bottom of each lap with a router plane.Thanks for the replies, but I'm trying to steer clear of using a table saw for 2 reasons; 1) the diagonals I want to slot are 8+ ft long and my shop is too crowded for that, and 2) I'll be moving to a retirement home (too) soon and there's no space for a table saw. The workbench I am building will actually be built at the new residence. I am trying to cut some of the material first to make the transition to the new shop faster. Bench will go in the garage and will be 2' deep and 16' long.

Another plus for making by hand is your stock is face up so that you can see what you are doing.Like pop-pop said this is where hand saws and careful layout prevails. In many cases by the time you workout the setup for your power tools you can actually have the job complete with hand tools. So really you may want to give it some thought.

Also, if you have never made a first-class saw cut, this is an ideal opportunity to learn.

Mastering Handsaw Cuts - Lee Valley Tools

LATEST FOR SALE LISTINGS

-

-

-

SOLD -- $75: Gast moa v113 Vacuum Pump Veneer, 60" bag and board

- Started by peterdnight

- Replies: 1

-

GONE: Gladiator 5 cleats, 10 hangers, Paper Towel and Shelf

- Started by peterdnight

- Replies: 3

-

SOLD -- $100 Makita mac700 portable air + grex pin nailer + 2 others + 50' hose

- Started by peterdnight

- Replies: 1