You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Problem With 14" Bandsaw

- Thread starter jpmcn

- Start date

Take a look at the thread link below. I thought my bandsaw was messed up as well but after getting advice from this thread I was able to dial it in. In the thread there are some references to a video that Alex Snodgrass has on YouTube. I found this very helpful.

Ultimately, for me it was all about getting the blade to track with the gullet centered on the wheels first. Look at your tires, if they are dirty, clean them. If they can’t be cleaned (like squeaky clean), replace them. Once you get that right, the guides should not be used to position the blade in any way. Think of them as a back up for movement when pressure is applied to the blade.

ncwoodworker.net

ncwoodworker.net

Ultimately, for me it was all about getting the blade to track with the gullet centered on the wheels first. Look at your tires, if they are dirty, clean them. If they can’t be cleaned (like squeaky clean), replace them. Once you get that right, the guides should not be used to position the blade in any way. Think of them as a back up for movement when pressure is applied to the blade.

Bandsaw Fence Adjustment Question

I bought a used Laguna 18BX today. Seems like this thing was used pretty hard and no really maintained very well. I'm trying to adjust the fence and to get it square with the blade, it's way out of square with the table. Take a look at the picture you can see the difference between the fence...

Good advice by Wilsoncb. The video here is the exact process I go through to set up my saw now and it works like a champ, even though I don't enjoy taking off the bed because its heavy. I would try this first before looking in to replacing parts.

What symptoms make you conclude that these components are defective?

Why do you think you need to replace the tensioning device?Having problems with my Jet JWBS-14CS 14"Bandsaw. Problem with tensioning, tracking, and installing a blade. Looks like I Will have to replace the tensioning and tracking part. Has anyone had similar problems with a Bandsaw and what did you do?

What do you mean by "tracking"? Tension, blade alignment, and thrust adjustment bearing all play a role in how well you're tracking. You may also need to adjust the fence, too.

When I did get the blade installed, it tracked off the front of the wheel. I had the Laguna 3/4" resaw Blade on the saw and it tracked almost off of the wheel. I thought it did that because I had been told that a 3/4" blade should not be used on a 14" Bandsaw, even if manufacturer says it is rated for the 3/4". I removed the 3/4 " blade and attempted to install a 1/2", but can't install it.What symptoms make you conclude that these components are defective?

I do have the manual and I said in my reply that although the manufacturer says that the saw can use a 3/4" blade. Maybe it is because my saw is about 30 years old.Do you have the manual? Did you read it?

I have a Jet 14" and it handles a 3/4" blade just fine.

There's probably a section in the manual that describes the installation procedure. You said you couldn't install a 1/2" blade. Why? Like I said, instructions for installing a new blade, will be in the manual. How to adjust tracking will be in there too.I do have the manual and I said in my reply that although the manufacturer says that the saw can use a 3/4" blade. Maybe it is because my saw is about 30 years old.

There should be a nob on the back of the unit that is used to position the blade on the wheel. That's where you adjust the top wheel, so the blade's gullets are in the right spot.

Without being there, all we can do is speculate.

My opinion is that the crown on your tires has worn to the point that it will not hold the blade. This is routinely common on old band saws. Flat bands run in the middle of crowned wheels. That's a fact of physics. If the tire's crown is worn off, the band will want to ride on either rim of the wheel because the rim has now become the crown.

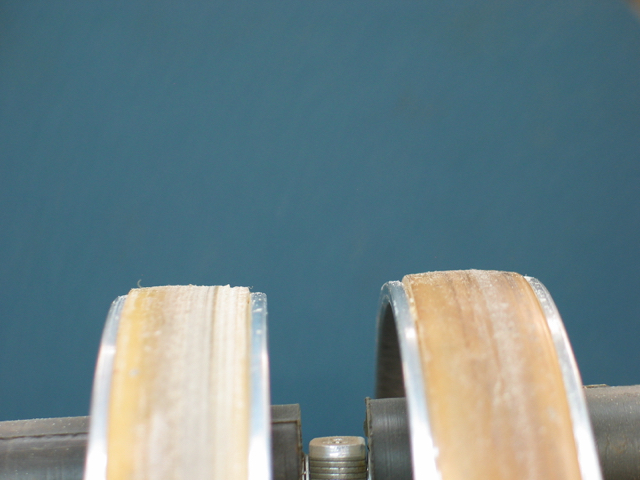

This is what a proper crown can look like.

Below are poly tires from a bargain basement Asian import 14" band saw. The crowns are gone and the blade would wander off the tire every time it was installed. I put a new crown on the tires and things were good again.

My opinion is that the crown on your tires has worn to the point that it will not hold the blade. This is routinely common on old band saws. Flat bands run in the middle of crowned wheels. That's a fact of physics. If the tire's crown is worn off, the band will want to ride on either rim of the wheel because the rim has now become the crown.

This is what a proper crown can look like.

Below are poly tires from a bargain basement Asian import 14" band saw. The crowns are gone and the blade would wander off the tire every time it was installed. I put a new crown on the tires and things were good again.

Similar issues? Yes on the same saw; mine is the old 'blue' version of Jet, but I doubt they changed much.Having problems with my Jet JWBS-14CS 14"Bandsaw. Problem with tensioning, tracking, and installing a blade. Looks like I Will have to replace the tensioning and tracking part. Has anyone had similar problems with a Bandsaw and what did you do?

I forget the details, but I have certainly replaced the blade tensioning bracket (and the screw and spring?); I heard mine crack, so I went looking for what was wrong. If I recall correctly, it had to be under tension for me to be able to see the crack, but it was obvious then. Replacement was relatively easy.

Side note - I have never been 100% happy with the saw (and the tracking specifically). Yes, I have seen the Snodgrass videos and believe I have it set up correctly - but I never get the performance he shows. I have not replicated his blade etc. conditions exactly either. This is my only bandsaw aside from a (POS) 3 wheeled tabletop Delta that snapped blades as soon as I added any tension; gave that one away with full disclosure of my experience.

EDIT - tonight I used a thin blade 1/4" or less, with a higher tooth count for scrolling cuts in thin plywood - and it worked very well. I don't know anything about the blade specifics, as the previous owner threw it in a part of the package. Saw could tension blade well. But then cutting 1/4 plywood is not the most demanding task.

Last edited:

Wheel crown has a lot to do with tracking. I've had this same saw for decades with no real issues with the saw itself. If you haven't already, familiarize yourself with matching blade tension with blade size. Those tensioners rarely if ever need replacing unless of course if they're over tensioned. Also note; check the weld on the blade. Some cheaper blades have a all so slight ridge at the weld. If that happens it's impossible to get it to track correctly. The best saw is only as good as the blade it's running.

Finally a fellow woodworker and I fixed my bandsaw. The problem was that the sliding bracket assembly had to be replaced. The upper wheel shaft had a crack at the connection to the shaft hinge. The part is part no. 100016ACP and it was ordered from eBay at a cost of $65.00 plus shipping.Having problems with my Jet JWBS-14CS 14"Bandsaw. Problem with tensioning, tracking, and installing a blade. Looks like I Will have to replace the tensioning and tracking part. Has anyone had similar problems with a Bandsaw and what did you do?

I remember working on an 18" Jet bandsaw that was hard to track.

One of the members here needed help with a complete shop tune up.

The upper arm was made of sheet metal and flexed more than 1/2" quite easily.

That's when I decided to stay away from Jet.

One of the members here needed help with a complete shop tune up.

The upper arm was made of sheet metal and flexed more than 1/2" quite easily.

That's when I decided to stay away from Jet.

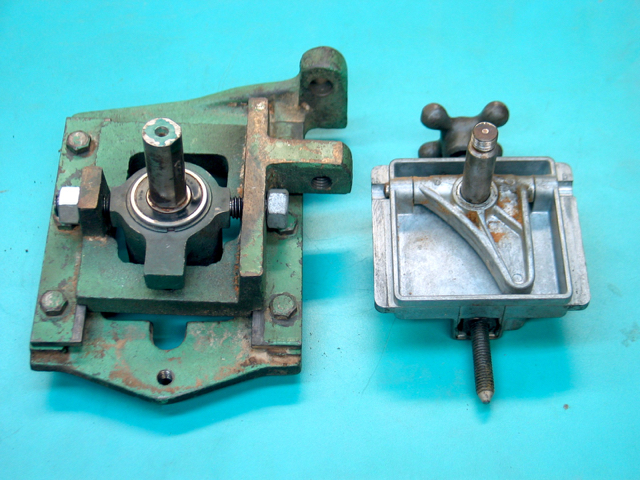

That upper hinge design has always been a weak point because it was made out of cast aluminum (and later Asian pot metal). Heavy downward pressure of wide blades over time can crack the flimsy hinge. Back when I was rebuilding a lot of machines, I'd keep three to five hinges in stock at all times. The USA-made Powermatic machines never had that problem because of their far more durable cast iron design.

The Delta-design upper hinge assembly is most comfortable with blades 1/4" to 3/8". Because the manuals tell you that you can put a 3/4" blade on that design doesn't mean you should.

Powermatic 141/143 14" band saw cast iron upper hinge assembly on the left. On the right is a USA-made cast aluminum Delta hinge assembly from the 1950s.

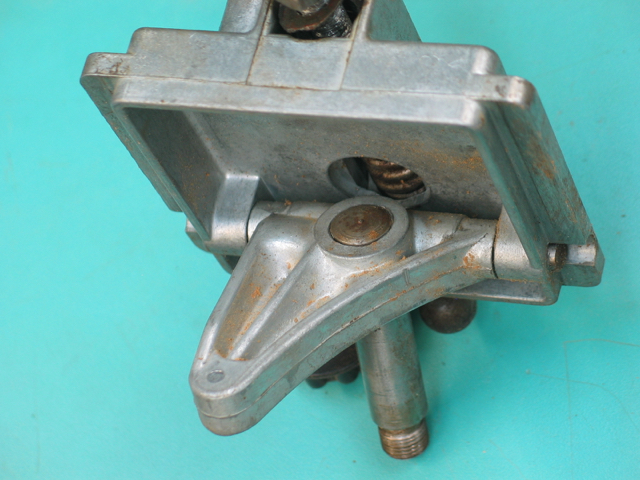

The back side of the Delta assembly.

The Delta-design upper hinge assembly is most comfortable with blades 1/4" to 3/8". Because the manuals tell you that you can put a 3/4" blade on that design doesn't mean you should.

Powermatic 141/143 14" band saw cast iron upper hinge assembly on the left. On the right is a USA-made cast aluminum Delta hinge assembly from the 1950s.

The back side of the Delta assembly.

I am bit late to this conversation, but just went through this with my Jet, which is the same as yours. I couldn't tension the blade correctly or adjust its tracking right. Turns out that the angle of the axle shaft to the casting had changed over time and is now less that 90 degrees on my machine. It was causing the lower point of the hinge triangle that the tracking adjuster bears on to hit the bottom of the lower cutout on the upper blade guard. I ended up having to create a cutout on the guard that allows the extra travel needed to avoid the interference fit. Works ok now. I guess I need to save up for a new hinge piece, or better, a new saw! I have to admit that it has been a good saw to me for the 25 years I have owned it.

It looks like someone is making an improved upper hinge assembly for the delta, which I’m guessing also works with the imports:

I’m hoping this isn’t ripped off from Iturra design.

Delta 14'' Bandsaw Upper Wheel Tension Assembly w/Iron hinge upgrade | eBay

This 14" Bandsaw Upper Wheel Shaft & HInge Assembly that interchanges with Delta, Ridgid, Central Machinery and most import 14" bandsaws. Complete with new wheel bearings and shaft nut. Getting desperate.

www.ebay.com

I’m hoping this isn’t ripped off from Iturra design.

LATEST FOR SALE LISTINGS

-

-

-

SOLD -- $75: Gast moa v113 Vacuum Pump Veneer, 60" bag and board

- Started by peterdnight

- Replies: 1

-

GONE: Gladiator 5 cleats, 10 hangers, Paper Towel and Shelf

- Started by peterdnight

- Replies: 3

-

SOLD -- $100 Makita mac700 portable air + grex pin nailer + 2 others + 50' hose

- Started by peterdnight

- Replies: 1