Seeking advice with panel glue ups. I’ve only completed a few, but my project requires much larger than I’ve done before. Is my set up incorrect or is there something better I should be doing? I don’t have a biscuit joiner but am interested in getting one. I’m too much of a hobbiest to justify getting into dominos. I am getting about .019 differences in spots. Is this an acceptable tolerance? Any advice would be much appreciated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Panel glue-up

- Thread starter Nicholsjr

- Start date

I have a craftsman 6in jointer from the 70s. It has relatively new blades and I routinely reset them with a jointer pal. The fence is awful though. After running through table saw I smooth any blade marks with a block plane.A good glue setup won't fix bad joints. How are you jointing the edges of your boards?

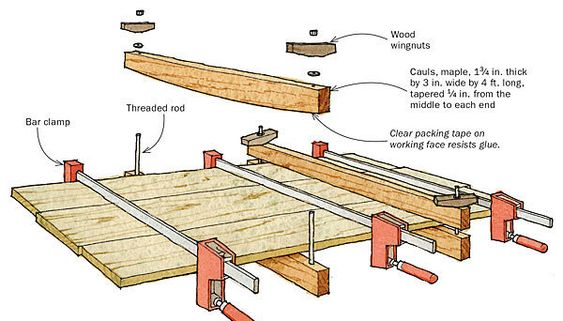

I would say you need to have cauls more in the middle.

The curvature of the cauls is exaggerated in this drawing.

The curvature of the cauls is exaggerated in this drawing.

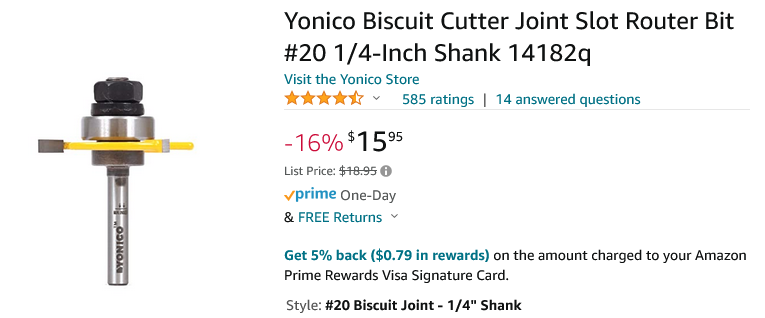

If the panel face alignment is your concern, a biscuit joiner is another solution. Technique is important though - you need to be careful to support the motor end of the joiner while cutting but with practice, you'll end up with really good alignment between the panels. I haven't measured, but quite a bit better than 19 thousanths.

Since you have a jointer, after table saw cuts, why don't you just run the board back over the jointer to get rid of saw marks? And finally, it doesn't sound like gaps between the joined surfaces is an issue, but since you mentioned the jointer, I'm wondering if you have concerns with that. Are you sure you're getting straight joints?

Since you have a jointer, after table saw cuts, why don't you just run the board back over the jointer to get rid of saw marks? And finally, it doesn't sound like gaps between the joined surfaces is an issue, but since you mentioned the jointer, I'm wondering if you have concerns with that. Are you sure you're getting straight joints?

Last edited:

I am not sure if it is correct or not but I use far more clamps. Alternating over and under about every 8 inches apart. I would most likely use 8-10 clamps on a glue up of this length. I also find long pieces tough to get a straight edge as I have a smaller jointer as well. If the piece is greater than 1 1/2 times the length ofcmy jointer, I use a straight edge (festool track but used to use factory edge on MDF with flus trim bit)and router to get straight edges. Generally, if a glue up of less than 4’, I can get a straight edge straight off the table saw that is adequate for gluing.

Jordan, what Is the purpose of the dowels where the pipe clamps are applying pressure?

You've already got some good advice scattered throughout the previous replies. I'll pull them out and bundle them together. Do these things before you invest in a biscuit joiner.

- Put at least 2 more clamps across the width of the table top. Clamp exactly like you set the end clamps. 8"--10" is real close spacing IMO, but won't cause problems.

- Alternate the width clamps over/under. Don't over tighten; just enough pressure to force squeeze out.

- If you want to get down to .0001s of an inch, make cauls as in illustration above. Mine are just boards and I use clamps on the ends. A simple way to get the curvature is to divide the caul into sixths, then lay a strip of packing tape across the 2 center sections, then lay another strip across the 4 center sections, then lay a strip across the entire length of the caul. The build up of tape layers gives you just enough curvature to equalize pressure across the entire width.

- A card scraper is the safest way to deal with the unevenness you have now.

Put the boards on your table saw with the edge to be jointed pointing down. Set the blade so it cuts 1/2" deep. Set the fence so you can cut a groove with the outside of the blade on the centerline of the board. Push it through the saw and turn end for end and push it through again. That will give you a 1/4" wide dado centered on the board. Do the same with the other board. Get some pieces of scrap wood and cut 1/4" thick by just slightly under 1" wide splines across the grain, some pieces of 12" pine or what have you will do. Check the first one you make for fit in the dado and adjust the table saw if needed before you make all the splines. Make enough of those so you can span the entire top. You want the grain of the splines at right angles to the grain of the table top so you get maximum strenght. Put glue in both dados. Put the splines in one side of the top. then bring the other side onto the splines sticking out of the first piece. Clamp and clean the glue squeeze out up. Let it sit overnight.

When you joint the edges, before cutting dados as above, turn the two halves vertical with either face to face or bottom to bottom. Clamp them together so they can't shift. Then run across your jointer as if it was one piece. Any error in your fence will be mirrored on the two joining faces of the wood and they will match up perfectly as long as you don't let them cock up or cock down when passing over the jointer table.

When you joint the edges, before cutting dados as above, turn the two halves vertical with either face to face or bottom to bottom. Clamp them together so they can't shift. Then run across your jointer as if it was one piece. Any error in your fence will be mirrored on the two joining faces of the wood and they will match up perfectly as long as you don't let them cock up or cock down when passing over the jointer table.

Were the boards flat before glue up?

Won't the splines show on the end?Put the boards on your table saw with the edge to be jointed pointing down. Set the blade so it cuts 1/2" deep. Set the fence so you can cut a groove with the outside of the blade on the centerline of the board. Push it through the saw and turn end for end and push it through again. That will give you a 1/4" wide dado centered on the board. Do the same with the other board. Get some pieces of scrap wood and cut 1/4" thick by just slightly under 1" wide splines across the grain, some pieces of 12" pine or what have you will do. Check the first one you make for fit in the dado and adjust the table saw if needed before you make all the splines. Make enough of those so you can span the entire top. You want the grain of the splines at right angles to the grain of the table top so you get maximum strenght. Put glue in both dados. Put the splines in one side of the top. then bring the other side onto the splines sticking out of the first piece. Clamp and clean the glue squeeze out up. Let it sit overnight.

When you joint the edges, before cutting dados as above, turn the two halves vertical with either face to face or bottom to bottom. Clamp them together so they can't shift. Then run across your jointer as if it was one piece. Any error in your fence will be mirrored on the two joining faces of the wood and they will match up perfectly as long as you don't let them cock up or cock down when passing over the jointer table.

You've gotten some good advice. If the top is not cupped or twisted, and you have 1/2 mm to remove when done, I would say good job.Seeking advice with panel glue ups. I’ve only completed a few, but my project requires much larger than I’ve done before. Is my set up incorrect or is there something better I should be doing? I don’t have a biscuit joiner but am interested in getting one. I’m too much of a hobbiest to justify getting into dominos. I am getting about .019 differences in spots. Is this an acceptable tolerance? Any advice would be much appreciated.

Thank you all for the great advice. I have reviewed them and will make some changes like more clamps, cauls in the middle (going to try the packing tape technique), over under position of the clamps. I also looked at my clamps and notice a lot of old dry glue remaining. I’m going to scrape those clean to ensure they are not adding to my issue. I will also start looking into a biscuit joiner but will continue to work on technique.

Let’s hope the second panel I need to make benefits from these tips.

Let’s hope the second panel I need to make benefits from these tips.

I read this in a very old family handyman magazine. Article explained the dowel directs the pressure to the center of the board and reduces bowing. I also read in an old thread here (about pipe clamps) this can be useful as long as the dowel is in the center of the board.Jordan, what Is the purpose of the dowels where the pipe clamps are applying pressure?

Make two short splines, like 1" long and insert at each end leaving 1/16" or so proud of the surface. Sand them off flush when you finish the table top. Yes, you might see them, and the problem is? To me that kind of thing makes a project look like it was hand made not mass produced and shows the skill you used in making it.Won't the splines show on the end?

Jordan, the keys to a good panel glue up are not starving the joints, and properly jointed edges. Other irregularities like bows can be dealt with. boards they aren't really needed.

Jointing: The face in/face out method of alternating against the jointer fence cancels out any minor discrepancy off 90.

Cauls: IMO cauls are more for keep the joints flush. In the case of panels with several narrow boards, they are needed to for both - flat and even. The reason is 8 joints (16 edges) vs. 2 joints (4 edges) have 4x that chances that even 0.1° of error will multiply. Balanced clamping will keep a panel flat.

Clamps: Pipe clamps produce a force vector that is not parallel to the pipe so panels tend to bow upward. Alternating is critical (but you can get away with it). A 1/4" spacer between the pipe and board will do two things:

Flush joints: On straight boards, alignment aids are not necessary. If they have a slight bow, I'll use biscuits and alternate bow up/bow down do balance out the forces.

I use a combination of increasing clamp pressure a some good whacks with a rubber hammer to bring the joints even. Work from one end to the other. That said, biscuits are a good insurance policy. A cheap alternative to a biscuit jointer is a biscuit router bit.

Post glue up:

Jointing: The face in/face out method of alternating against the jointer fence cancels out any minor discrepancy off 90.

Cauls: IMO cauls are more for keep the joints flush. In the case of panels with several narrow boards, they are needed to for both - flat and even. The reason is 8 joints (16 edges) vs. 2 joints (4 edges) have 4x that chances that even 0.1° of error will multiply. Balanced clamping will keep a panel flat.

Clamps: Pipe clamps produce a force vector that is not parallel to the pipe so panels tend to bow upward. Alternating is critical (but you can get away with it). A 1/4" spacer between the pipe and board will do two things:

- It puts the screw more inline with the panels, which makes the force vector more parallel.

- By preventing the pipe from bowing, it straightens out the force vector. Both these things make a pipe clamp more like a parallel clamp.

Flush joints: On straight boards, alignment aids are not necessary. If they have a slight bow, I'll use biscuits and alternate bow up/bow down do balance out the forces.

I use a combination of increasing clamp pressure a some good whacks with a rubber hammer to bring the joints even. Work from one end to the other. That said, biscuits are a good insurance policy. A cheap alternative to a biscuit jointer is a biscuit router bit.

Post glue up:

- I keep the panels thick, wide and long, so I don't worry about clamps indenting, or boards perfectly even lengthwise.

- That leaves the big issue which is flattening a panel. Many ways to do that hand planes, belt sanders, etc.

- Keep the panel in clamps and cauls until ready to use. After flattening a base coat of sealer can be applied.

- Keep the panel stored in a stable environment, no air movement, no sun, etc. I like to store large panels in a vertical position, as opposed to tying up a horizontal surface.

- Some wood like cherry I keep covered with a blanket. If I can't tie up clamps or for smaller panels, I usually put them in a plastic bag or seal in plastic film.

Couple of thoughts/ideas. First look at the glue bottle and READ how long you need to leave clamps on. It's not over night. Second when using biscuits, you need to allow extra time (as in days) before sanding. The moisture in the glue surrounding the glue swells the wood. If you sand too quickly, after swelling goes down, you will wind up with a divot in your finish at each biscuit location. DAMHIK!