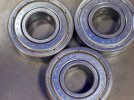

So, I bought a Unisaw and I am restoring it to near new condition. I Ordered up some Timken bearings because I wanted American, German or Japanese products.

Anyway, I needed a 6205 and a 6206 both were advertised as American made but much to my chagrin, one was made in China the other was American. Given these bearings are for the motor I am not going to send them back, I waited for 8 days to get them, just really pisses me off.

Word of Caution Nachi(Taiwan), NSK(Taiwan), and now Timken(China) are outsourcing some of their products. So the caveat now requires us to ask before buying.

Anyway, I needed a 6205 and a 6206 both were advertised as American made but much to my chagrin, one was made in China the other was American. Given these bearings are for the motor I am not going to send them back, I waited for 8 days to get them, just really pisses me off.

Word of Caution Nachi(Taiwan), NSK(Taiwan), and now Timken(China) are outsourcing some of their products. So the caveat now requires us to ask before buying.