Chamfers are a frequently used corner treatment in woodworking where you create a bevel along an edge. Aesthetically, they offer a way to visually lighten a piece, and practically, a way to protect a corner (i.e., it's hard to dent a corner that isn't there). Sometimes the chamfer runs the full length and other times it stops before reaching the end -- a stopped chamfer. How you stop a chamfer can be interesting in itself.

I am making some stopped chamfers on the parts of a chevalet (marquetry horse). The chamfer bevel is about 7/16" wide. I'm using a router table to cut the bevel, being sure to stop just before where it will end. I chose a plain stop for the chamfer to create crisp end to the bevel. A sharp chisel and a simple guide is all you need.

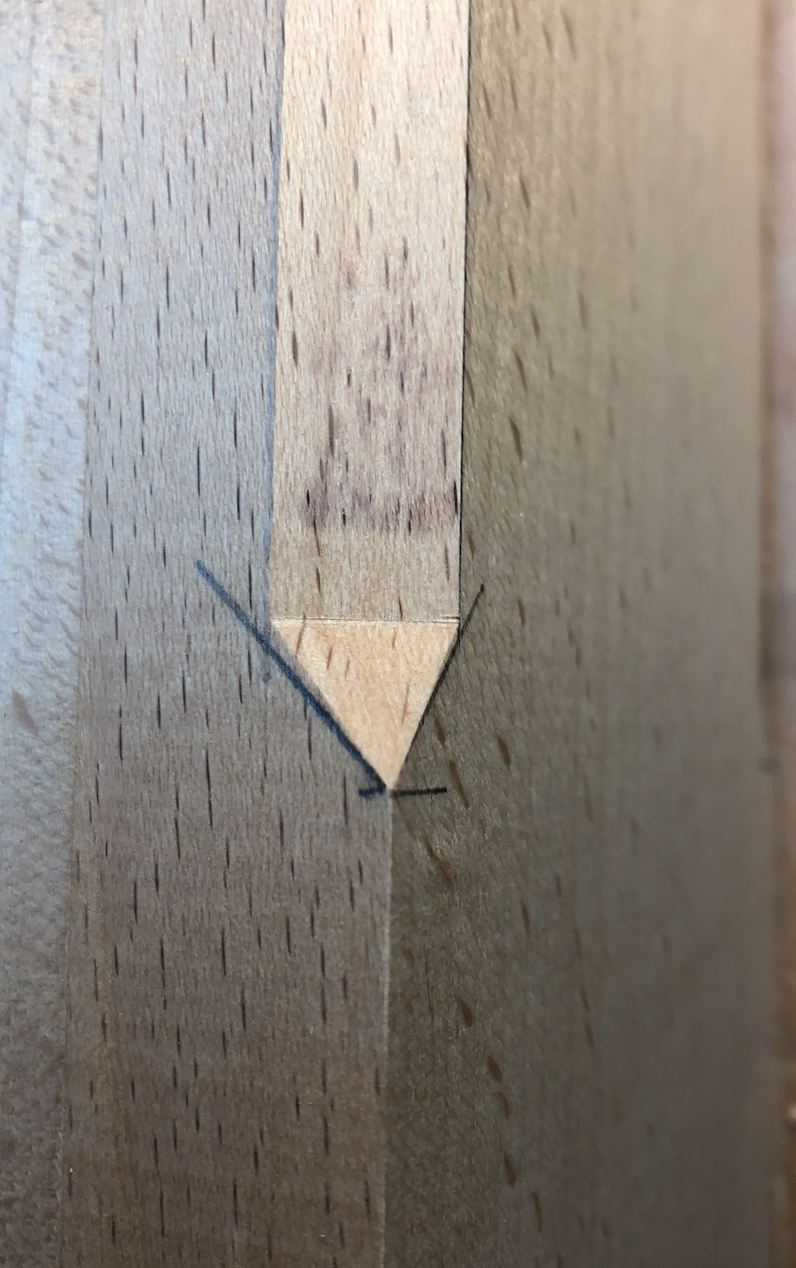

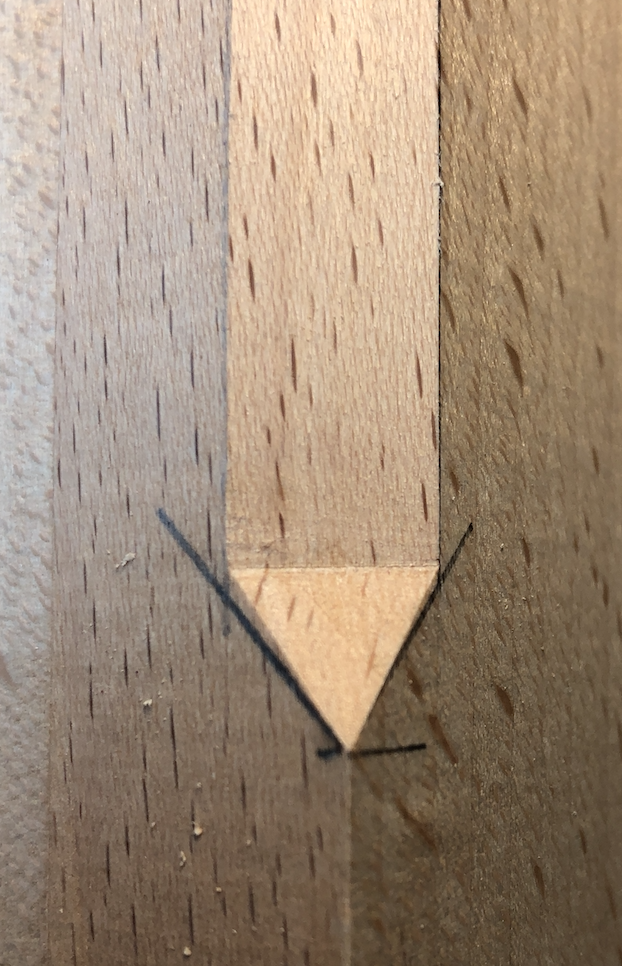

This is the end as it looks right off the router. You could stop here and leave it as a rounded stop. Note the rotation of the chamfer bit in the router does not produce a symmetrical end. This is something to take into account and run the work piece by reversing direction on adjacent corners rather than simply rotating the piece each time. This keeps the ends looking the same on each face, at least.

This is the end as it looks right off the router. You could stop here and leave it as a rounded stop. Note the rotation of the chamfer bit in the router does not produce a symmetrical end. This is something to take into account and run the work piece by reversing direction on adjacent corners rather than simply rotating the piece each time. This keeps the ends looking the same on each face, at least.

If you have a lot of these stops to make I find a guide block helps. It is nothing more than a square block with one of the corners removed (i.e., L-shaped at the end). Cut off one end at the angle you want by holding it at 45 degrees against the back of the miter saw.

If you have a lot of these stops to make I find a guide block helps. It is nothing more than a square block with one of the corners removed (i.e., L-shaped at the end). Cut off one end at the angle you want by holding it at 45 degrees against the back of the miter saw.

Run the back of the chisel down the guide to remove material at the proper angle.

Run the back of the chisel down the guide to remove material at the proper angle.

Flip the chisel around and run the back along the bevel to remove the chips. The goal is to get nice crisp lines and smooth faces.

Flip the chisel around and run the back along the bevel to remove the chips. The goal is to get nice crisp lines and smooth faces.

As a final step I use a card scraper to clean up any burn marks left by the router bit.

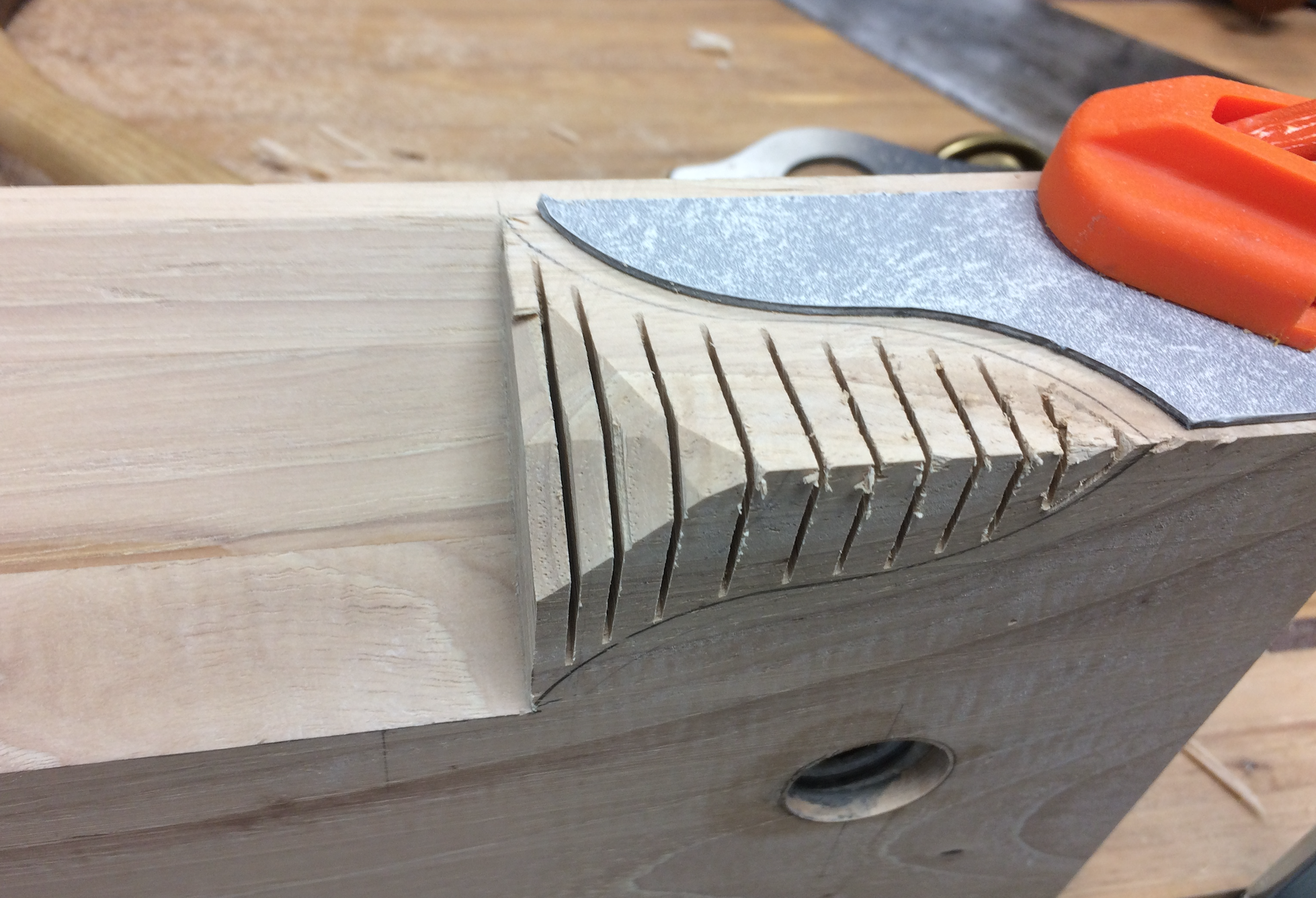

A more interesting chamfer stop is to use a "lamb's tongue". There are variations on this, but I used the one below on a Moxon vise. This is a large chamfer (> 2") that had to be cut by hand.

Once the chamfer was cut and smoothed I moved on to the lamb's tongue using the same procedure. Whereas a plane did most of the work smoothing the chamfer, smoothing the stop required rasps. Note the cardboard template used to define the shape of the stop.

I am making some stopped chamfers on the parts of a chevalet (marquetry horse). The chamfer bevel is about 7/16" wide. I'm using a router table to cut the bevel, being sure to stop just before where it will end. I chose a plain stop for the chamfer to create crisp end to the bevel. A sharp chisel and a simple guide is all you need.

As a final step I use a card scraper to clean up any burn marks left by the router bit.

A more interesting chamfer stop is to use a "lamb's tongue". There are variations on this, but I used the one below on a Moxon vise. This is a large chamfer (> 2") that had to be cut by hand.

Once the chamfer was cut and smoothed I moved on to the lamb's tongue using the same procedure. Whereas a plane did most of the work smoothing the chamfer, smoothing the stop required rasps. Note the cardboard template used to define the shape of the stop.

Last edited: