You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

making dowels

- Thread starter jcz

- Start date

I make my own dowels, I use a Lie-Nielsen dowel plate. The reason I make my own, is I rive the stock so it is straight grained, for use with a drawbored mortise and tendon joint.

Understand, it’s pretty impossible to make a dowel longer than 10 - 12 inches using a dowel plate, at least in my experience.

Understand, it’s pretty impossible to make a dowel longer than 10 - 12 inches using a dowel plate, at least in my experience.

Anyone have a tried and true way of making their own dowels? I have a need for 5/16" dowels and watched a few utube videos but am skeptical as to what is the best way.

how many do you need to make and or how often do you need to make them?

How long do you need to make them?

Will they "Show" or are they simply for structure?

There are various methods based on your needs.

Dowels need to be 8-9" long. I use them as the striker part for my turkey calls. So they will be see and handled. I have been buying them from a supplier but would like to make them as the ones I buy still need sanding to get to my liking.

I had previously seen top 2 videos. I tried a quick version of the old school video. It didn't turn out to good.

That is why I came here to ask how y'all did it.

I'll watch the 3rd video now. Got side tracked on utube watching wood turning. Lost 3 hours of my evening already. LOL

I had previously seen top 2 videos. I tried a quick version of the old school video. It didn't turn out to good.

That is why I came here to ask how y'all did it.

I'll watch the 3rd video now. Got side tracked on utube watching wood turning. Lost 3 hours of my evening already. LOL

I had never heard of a dowel plate before. Just checked Lie-Nielsen’s website and I think I found my next tool purchase when they are back in stock…I make my own dowels, I use a Lie-Nielsen dowel plate. The reason I make my own, is I rive the stock so it is straight grained, for use with a drawbored mortise and tendon joint.

Understand, it’s pretty impossible to make a dowel longer than 10 - 12 inches using a dowel plate, at least in my experience.

I have not done it, only on the lathe...I tried a quick version of the old school video. It didn't turn out to good.

But now I am curious, what "didn't turn out good" with this technique?

I think you can do the izzy swan version for 8", but I think you will struggle trying to "punch / push a dowel through a dowel plate... JMHO

Drilling / spinning the dowel through the plate will likely have better results...

Remember you want to use nice, strait grained wood for this and if you can get green and or air dried wood it is better...

I the one from DFM Toolworks that you can see in the second video that Hank postedI had never heard of a dowel plate before. Just checked Lie-Nielsen’s website and I think I found my next tool purchase when they are back in stock…

I think I had too large of a gap on top and the end of my dowel kept jumping out of the slot and my chisel ate the end up. Did a punch plate and tried hammering same dowel thru. It just mushroomed the 1st 1/4" and stopped.

I'll try the router method tomorrow. But I'm a little leary of it because my stock is so small.

I'll try the router method tomorrow. But I'm a little leary of it because my stock is so small.

If you are in a production mode------buy them!!

I’ve been eying the veritas version.

also only suitable for short custom dowels.

https://www.leevalley.com/en-us/sho...-and-tenon-cutters/70555-veritas-dowel-former

also only suitable for short custom dowels.

https://www.leevalley.com/en-us/sho...-and-tenon-cutters/70555-veritas-dowel-former

wood peck dowel press looks interesting but pretty pricey if they will make them again

www.woodpeck.com

www.woodpeck.com

OneTIME Tool - DOWEL PRESS - 2016 - Retired October 31, 2016

Make Perfect Dowels for Decorative or Blind Joinery from Any Wood Species DIY Dowels Right in Your Shop. Woodpeckers latest OneTIME Tool, the Dowel Press, makes it easy to produce more dowels than you can shake a stick at. And you can make them in numerous sizes in any wood species from ash to...

I dont know where I found this originally, but it works very well

Take a piece of metal, drill the size hole you need. Using a dremel, cuts slots in the hole

Create square stock just a hair biger than your finished dowel. Taper one end. Attach one other end to your drill, run through the hole

Take a piece of metal, drill the size hole you need. Using a dremel, cuts slots in the hole

Create square stock just a hair biger than your finished dowel. Taper one end. Attach one other end to your drill, run through the hole

I'm certainly not into production of these. I build a few calls at a time. I just got a bunch of laminate wood from another member here and the scraps he gave me are perfect for my strikers. I just need to get them rounded out the best and easiest way. I could do it on the lathe but that is time consuming.

Mike I'll give that a try. I will drill a couple holes in a piece of scrap metal and see what happens.

Thanks to all for the ideas and suggestions.

Mike I'll give that a try. I will drill a couple holes in a piece of scrap metal and see what happens.

Thanks to all for the ideas and suggestions.

A hinge works well I heard or red somewhere (probably an exterior hinge) thinking because it is possibly case hardened???I'm certainly not into production of these. I build a few calls at a time. I just got a bunch of laminate wood from another member here and the scraps he gave me are perfect for my strikers. I just need to get them rounded out the best and easiest way. I could do it on the lathe but that is time consuming.

Mike I'll give that a try. I will drill a couple holes in a piece of scrap metal and see what happens.

Thanks to all for the ideas and suggestions.

I would guess angle iron would be good...

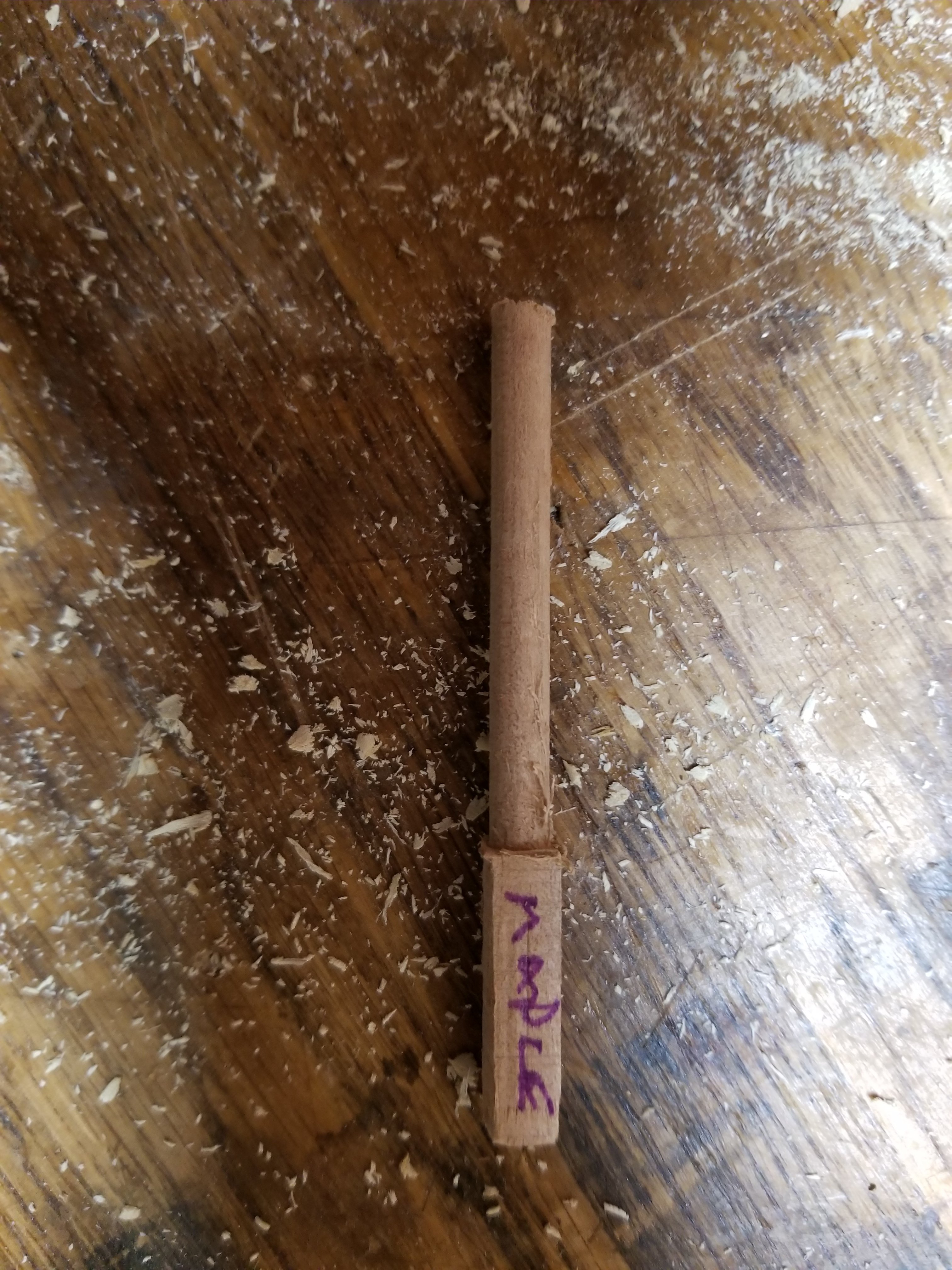

Mike's suggestion is what worked the best for me. I had piece of metal that had 2 1/4" holes in it already. I drilled them out to 21/64th and 23/64th. Then used a dremel and cut slots like his example. It worked perfectly. Had to round over both ends of the squared dowel on the belt sander. Put one end in my drill and drilled it thru the larger hole 1st then the smaller one. They now look exactly like the dowels I purchase. Slightly over 5/16" and in need of a little sanding to clean up the swirl marks.

Thanks again for the help every one.

Thanks again for the help every one.

I use a dowel plate. It works great.Anyone have a tried and true way of making their own dowels? I have a need for 5/16" dowels and watched a few utube videos but am skeptical as to what is the best way.

LATEST FOR SALE LISTINGS

-

-

-

-

SOLD -- $75: Gast moa v113 Vacuum Pump Veneer, 60" bag and board

- Started by peterdnight

- Replies: 1

-

GONE: Gladiator 5 cleats, 10 hangers, Paper Towel and Shelf

- Started by peterdnight

- Replies: 3