I have a Delta Lathe, the model 46 525. I modified the unit with a 2 hp 3ph w/ VFD.

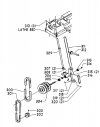

Anyway, the bearings were getting noisy (they were always noisy), so replacing them (6205zz and 5205zz).

Since I am there- I am thinking I might want to change the pulleys to double belt type. Any concerns with this?

The other question: anyone have any comments or experience changing the ratios on these?

I am thinking of changing the aspect from 2" motor to 5" spindle pulleys to - 3" to 4.25" . This would allow the motor @ 100% (3450 rpm) top spin the spindle roughly turn @ 2400. The original motor was 1 hp I figure there is enough torque with the bigger motor to accommodate.

I don't do pens, so I cannot think of any other instance where I would need a higher rpm.

Ideas, reflections and comments appreciated.

Anyway, the bearings were getting noisy (they were always noisy), so replacing them (6205zz and 5205zz).

Since I am there- I am thinking I might want to change the pulleys to double belt type. Any concerns with this?

The other question: anyone have any comments or experience changing the ratios on these?

I am thinking of changing the aspect from 2" motor to 5" spindle pulleys to - 3" to 4.25" . This would allow the motor @ 100% (3450 rpm) top spin the spindle roughly turn @ 2400. The original motor was 1 hp I figure there is enough torque with the bigger motor to accommodate.

I don't do pens, so I cannot think of any other instance where I would need a higher rpm.

Ideas, reflections and comments appreciated.