I support myself completely doing this work and have for several years. Gave up an engineering career to do it. I love doing this - got tired of dealing with my peers in exec mgmt.

So far, I have not experienced anything that would "ruin a hobby" I think as BAS said. I have though, given away a great deal of my time in the form of eating underpriced work. About 20% of my customers pay what it's worth, about 40% cringe at the price and go with it anyway, and the balance I never see again.

Everyone appreciates "knowing" they are getting custom made, but very few realize what it takes a craftsman to produce it. Therein lies the problem. If someone doesn't care about the shoe moulding in the living room not being coped at inside corners (which means they will open up), or they really like that Chinese-made buffet from Pottery Barn, you may have a problem getting them as a customer. If, on the other hand, they know there's a difference between mortise and tenon and pocket hole joinery AND know why one is better, you stand a much better chance. Now explain to the customer that they have to pay for something they will never see: (M&T joints) and materials that are far superior (furniture-grade plywood versus Home Depot plywood) - or better yet, solid wood. The Pottery Barn piece will sit in the dining room for 100 years with no problem and so will your custom piece. So why should I pay for better plywood, M&T joints, etc.? Be ready with a good answer, and if you find an answer that works really well, please share with all of us!

If you need to earn $100,000 annually, that equates to roughly $50/hour at a 40-hour week. The desk you are going to make could take a week to design, select materials and purchase, lay out and cut, make joinery cuts, assemble, sand/prep for finish, finish, and deliver. You are starting at $2000 + materials + wear-and-tear on machines (blades have to be resharpended and eventually replaced, bearings wear out, etc.). If you only need to make $50,000, that gets you to a $1000 starting point. You can see where I'm going with this.

In any case, I would be thrilled to know how this comes out. Would you be willing to keep track of the time you spend in each phase and report back here? Of course, we'd love to see your photos too.

Best wishes to you for a successful outcome - and many more!

So far, I have not experienced anything that would "ruin a hobby" I think as BAS said. I have though, given away a great deal of my time in the form of eating underpriced work. About 20% of my customers pay what it's worth, about 40% cringe at the price and go with it anyway, and the balance I never see again.

Everyone appreciates "knowing" they are getting custom made, but very few realize what it takes a craftsman to produce it. Therein lies the problem. If someone doesn't care about the shoe moulding in the living room not being coped at inside corners (which means they will open up), or they really like that Chinese-made buffet from Pottery Barn, you may have a problem getting them as a customer. If, on the other hand, they know there's a difference between mortise and tenon and pocket hole joinery AND know why one is better, you stand a much better chance. Now explain to the customer that they have to pay for something they will never see: (M&T joints) and materials that are far superior (furniture-grade plywood versus Home Depot plywood) - or better yet, solid wood. The Pottery Barn piece will sit in the dining room for 100 years with no problem and so will your custom piece. So why should I pay for better plywood, M&T joints, etc.? Be ready with a good answer, and if you find an answer that works really well, please share with all of us!

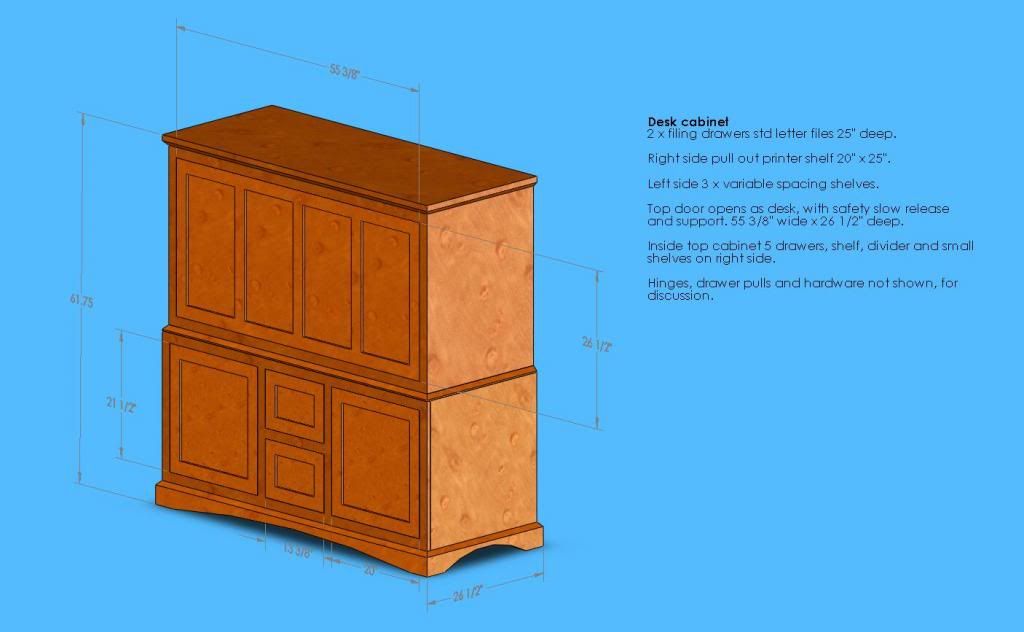

If you need to earn $100,000 annually, that equates to roughly $50/hour at a 40-hour week. The desk you are going to make could take a week to design, select materials and purchase, lay out and cut, make joinery cuts, assemble, sand/prep for finish, finish, and deliver. You are starting at $2000 + materials + wear-and-tear on machines (blades have to be resharpended and eventually replaced, bearings wear out, etc.). If you only need to make $50,000, that gets you to a $1000 starting point. You can see where I'm going with this.

In any case, I would be thrilled to know how this comes out. Would you be willing to keep track of the time you spend in each phase and report back here? Of course, we'd love to see your photos too.

Best wishes to you for a successful outcome - and many more!

![assembly revised[1].jpg assembly revised[1].jpg](https://ncwoodworker.net/forums/data/attachments/4/4803-dea75d2bb98fc69445b4b7845e32cac3.jpg)