Opinions please. I’m making a nightstand that has several pieces of molding; top, middle and bottom. Am I okay just gluing it or do I need something else, like backside screws? Think something like 1/2” quarter round under the top that extends out an inch or so from the sides (more detailed than quarter round but that’s the general idea). And think years down the road as legacy furniture. Am I overthinking it that I need screws? If it matters, red oak on 3/4” oak veneer plywood. Thanks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Furniture molding

- Thread starter Robinsage0279

- Start date

I usually use small gauge pin nails on molding in addition to glue. No screws

Last edited:

Do you have any panels, top, shelves, legs, etc that are glued up of multiple pieces?

Do you think they would hold up longer than a molding that just sits there?

Do you think they would hold up longer than a molding that just sits there?

The top is two pieces but with 3/8” dowel’s. The inside frames are mortise & tendons. The front face are doweled. Frame and faces to sides are pocket screwed. I know glues (in this case TB2) are better nowadays, but I’ve seen older furniture with glues drying and cracking over time. As I said, am I overthinking?Do you have any panels, top, shelves, legs, etc that are glued up of multiple pieces?

Do you think they would hold up longer than a molding that just sits there?

Well we don’t have 100 year performance reports but I would go with glue only.

Glue should suffice because the sheet goods aren't subject to changes in humidity. However, you might want to use brads or pin nails to keep the molding from sliding around when you're trying to glue it. You can also drive small finish nails into the plywood, clip off the heads and leave very short stubs, and these will act as cleats to hold the molding in place while the glue cures. Good luck with it!

Just be sure you're not creating a "cross-grain" problem. Example: if you have panels that run vertical and you glue a piece of molding that rums horizontal, that can be a problem. The grain on the panels will expand and contract from side to side. The molding running length-wise across the grain will not expand. Something has to give.

Glue is OK with plywood panels, not OK on solid wood panels. According to the “rules” that would be a cross grain glue up. But you can get away with things….. Pin nails will bend with movement, but will not hold well enough IMO. If you were nailing finish nails would be best.

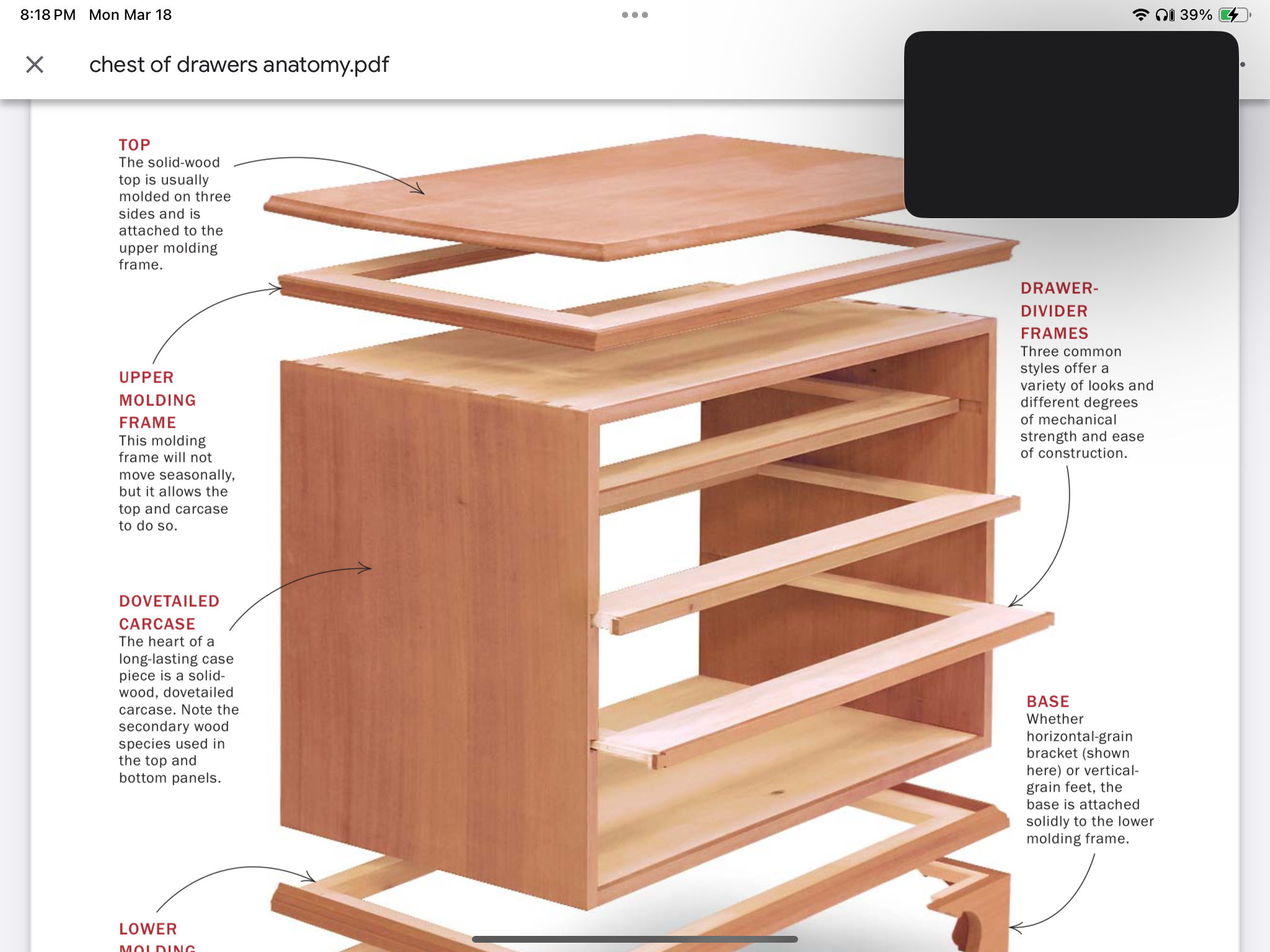

A traditional way to do this is a moulding frame and either attach the moulding or route the moulding on the frame edge.

A traditional way to do this is a moulding frame and either attach the moulding or route the moulding on the frame edge.

I'll crossgrain glue quite often and have yet to have problems. Small stick moulding, I'll glue and pin nail. Larger stuff, I'll pressure glue.

I am absolutely gluing the side runners on along with 18 gauge pins for positioning. Been doing that for at least 30 years with solid wood sides. Never a problem with the runners.

Below is my first nightstand from shelving pine. The top split early on but the side runners are still holding. The top split is from an overly aggressive screw.

Stand from shelving pine made in 1971.

A couple of night stands of walnut. The one on the left was made in 1997 and its still holding fine.

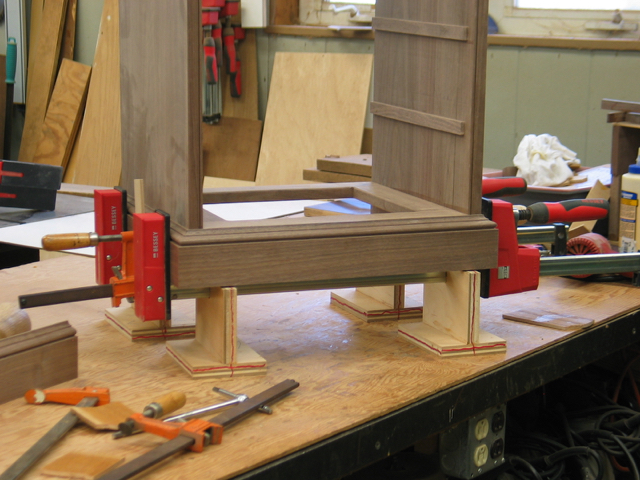

This is my typical method of attaching runners. It holds fine.

I'm aware of the nailing on of the trim. Those little square tapered nails seemed to hold applied ornamental trim well enough. Much of interior casework bracing was also nailed on. That's about all they had 250 years ago.

Below is my first nightstand from shelving pine. The top split early on but the side runners are still holding. The top split is from an overly aggressive screw.

Stand from shelving pine made in 1971.

A couple of night stands of walnut. The one on the left was made in 1997 and its still holding fine.

This is my typical method of attaching runners. It holds fine.

I'm aware of the nailing on of the trim. Those little square tapered nails seemed to hold applied ornamental trim well enough. Much of interior casework bracing was also nailed on. That's about all they had 250 years ago.

Despite the fact it’s working for you, that doesn’t mean you should disregard wood movement. All wood moves, what you can get away with depends in several factors. But genrally people will get in trouble disregarding it  .

.

Virtually everything I build shrinks when it goes inside. I have to build accordingly. Drawers a little tight in summer, a little loose in winter.

The top on my 42” wide dining table shrink 3/32” within 6 months after being inside. If I had glued the breadboards …..I’d be filling a crack.

Virtually everything I build shrinks when it goes inside. I have to build accordingly. Drawers a little tight in summer, a little loose in winter.

The top on my 42” wide dining table shrink 3/32” within 6 months after being inside. If I had glued the breadboards …..I’d be filling a crack.

Wow. That's a graphic example.

I once bought some 6% dried cherry. Built my chest of drawers. The 21" deep top expanded about 1/10" as it acclimated to my house. Popped the edge band. Usually things shrink. A lot can depend on the moisture content of the wood and the ambient of the area of intended use.

I once bought some 6% dried cherry. Built my chest of drawers. The 21" deep top expanded about 1/10" as it acclimated to my house. Popped the edge band. Usually things shrink. A lot can depend on the moisture content of the wood and the ambient of the area of intended use.

I just pin nailed some 5/8" cove molding on a small chest of drawers today. It is a woodsmith "heirloom cherry" plan. I could have used glue too but I know from experience pin nails will hold fine. Most of the wood it is fastened to has grain running parallel to the molding but the ends are frame and panel so the stiles are cross grain. But only about 3 inches wide. The top is fastened down with screws in elongated holes and is also finished the same on both sides (or it will be when I put on the second coat of Osmo tomorrow). You can find the pin nails if you get down on the floor and look for them but in normal use they are not visible.

LATEST FOR SALE LISTINGS

-

-

-

SOLD -- $75: Gast moa v113 Vacuum Pump Veneer, 60" bag and board

- Started by peterdnight

- Replies: 1

-

GONE: Gladiator 5 cleats, 10 hangers, Paper Towel and Shelf

- Started by peterdnight

- Replies: 3

-

SOLD -- $100 Makita mac700 portable air + grex pin nailer + 2 others + 50' hose

- Started by peterdnight

- Replies: 1