Several years ago I bought a nice Millers Falls hand drill at an estate sale. Previously I drilled holes with a pistol-grip tool and usually the holes were slanted one way or the other. Now, I use the hand drill almost exclusively especially for pilot holes. With the hand drill, getting the hole perpendicular is darn near automatic for me which was a pleasant realization.

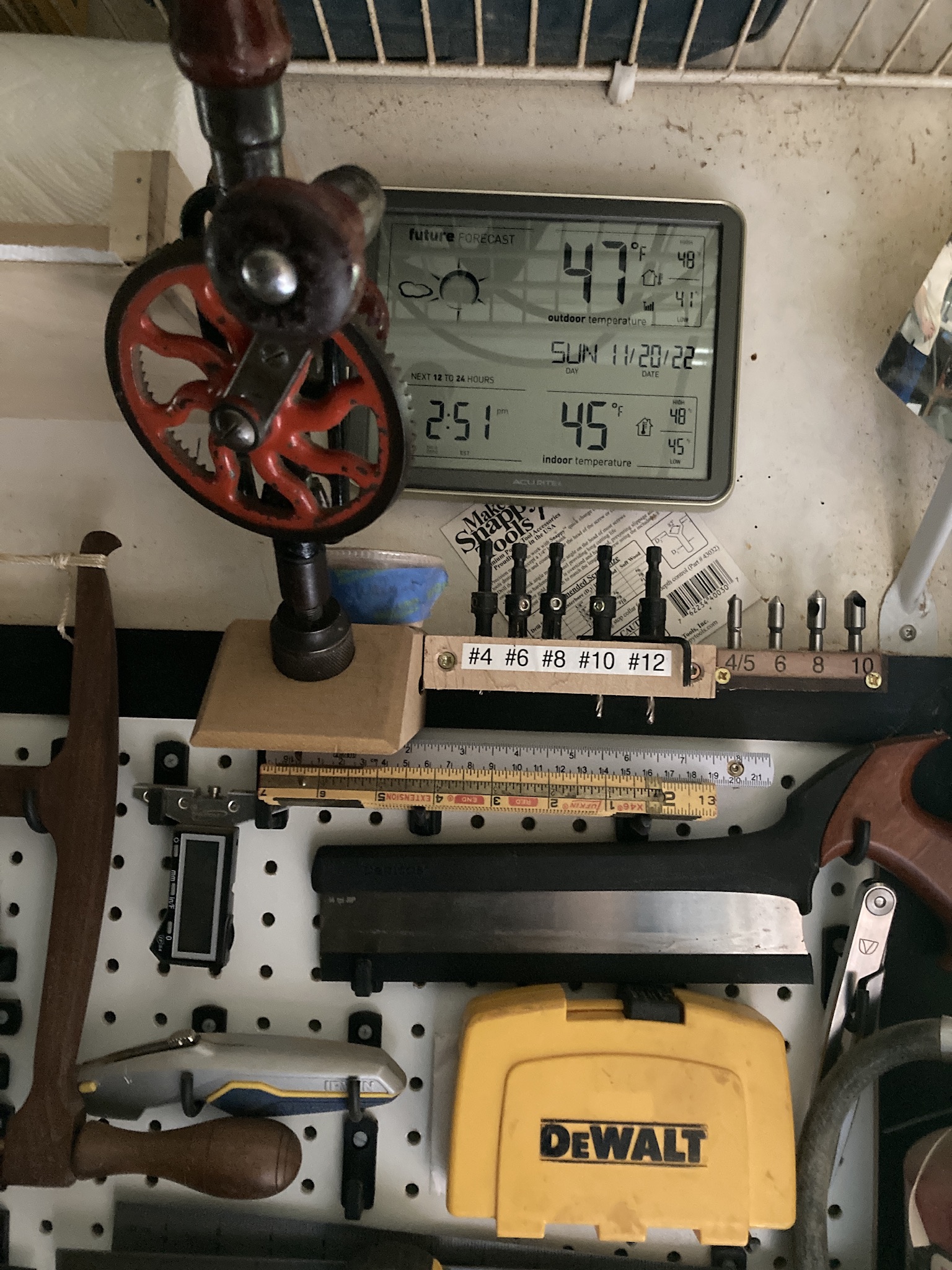

I stow the drill and bits within reach of when I work at my high vise.

I stow the drill and bits within reach of when I work at my high vise.