Two of the things I most enjoy about starting a new project is acquiring the tools needed and learning new skills. As tools and skills go this is a pretty minor one. It's a tool that's been on my list for some time to make, just waiting for the right project to come along.

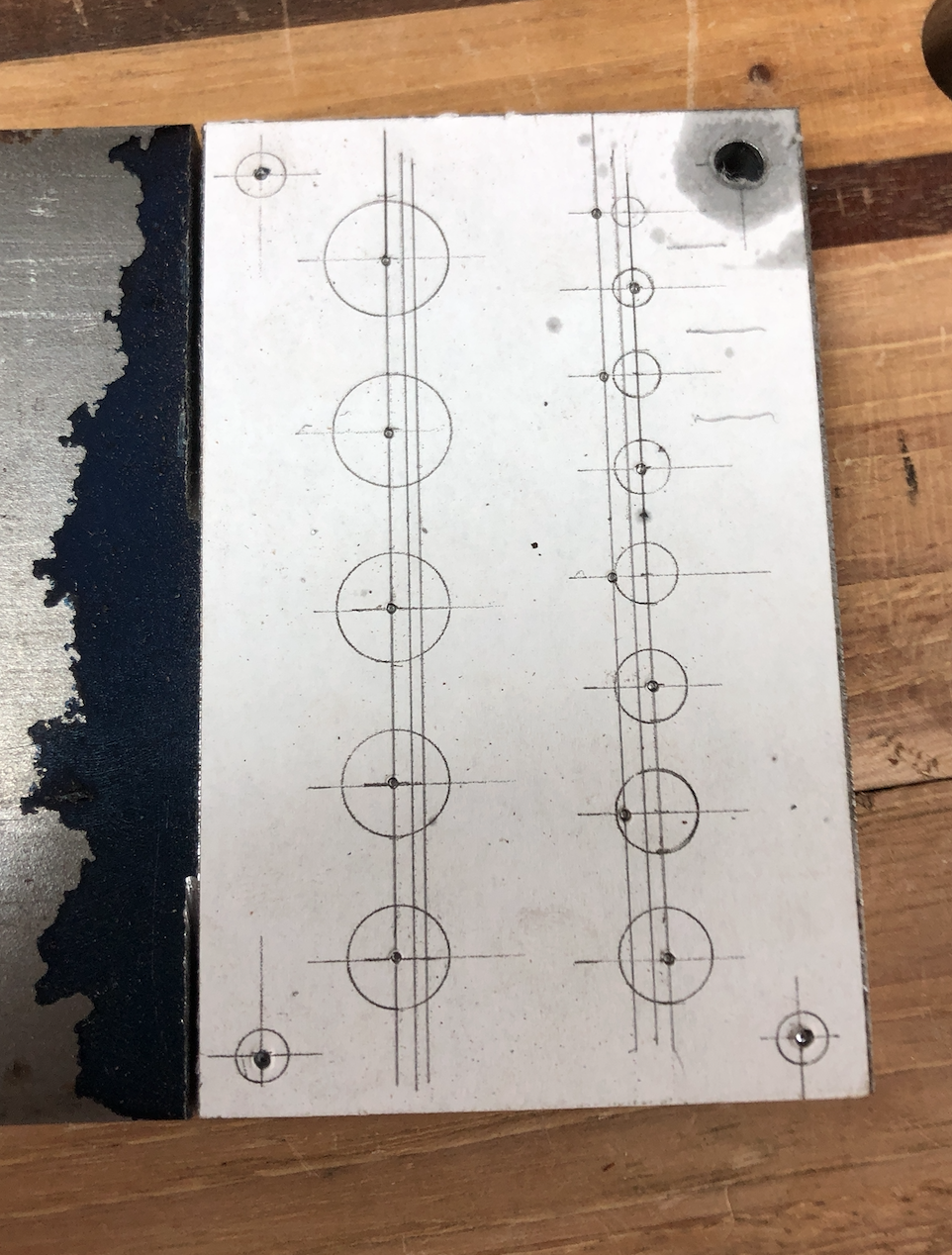

The desk I'm making for my wife will be pinned together, leaving the pins to show. This is a feature often seen on Queen Anne pieces. I wanted a dowel plate to use in making the pins. This was an easy project, but one with a lot of boring tasks (that one's for you @Hmerkle). Here's the result. The holes are true size on the face and then counter bored 1/32" larger from the other side, stopping just short of the top. The steel plate is 1/4" thick.

The desk I'm making for my wife will be pinned together, leaving the pins to show. This is a feature often seen on Queen Anne pieces. I wanted a dowel plate to use in making the pins. This was an easy project, but one with a lot of boring tasks (that one's for you @Hmerkle). Here's the result. The holes are true size on the face and then counter bored 1/32" larger from the other side, stopping just short of the top. The steel plate is 1/4" thick.