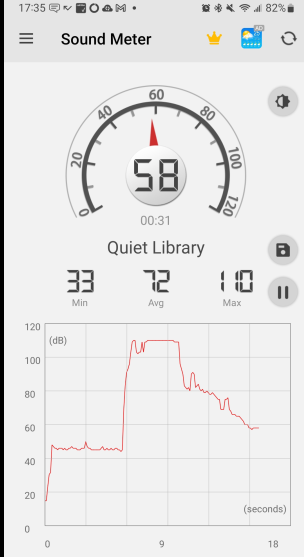

I'm in the process of installing a ClearVue 1800 (15" Impeller) that I purchased from another NC Woodworker. It is mounted and I'm now able to apply power to it, so I fired it. GEE WHIZ it is loud! Using an app on my phone I measured the noise level and was super surprised to see it was 110db. The max level is when the CV was running. I was expecting something in the range of 82-96 db.

I do have the mod where a block of wood is installed in the impeller housing. I'm planning to install a muffler (Bill Pentz) in a few weeks.

What have others experienced?

What did you do to reduce the noise and how much was the reduction?

I do have the mod where a block of wood is installed in the impeller housing. I'm planning to install a muffler (Bill Pentz) in a few weeks.

What have others experienced?

What did you do to reduce the noise and how much was the reduction?