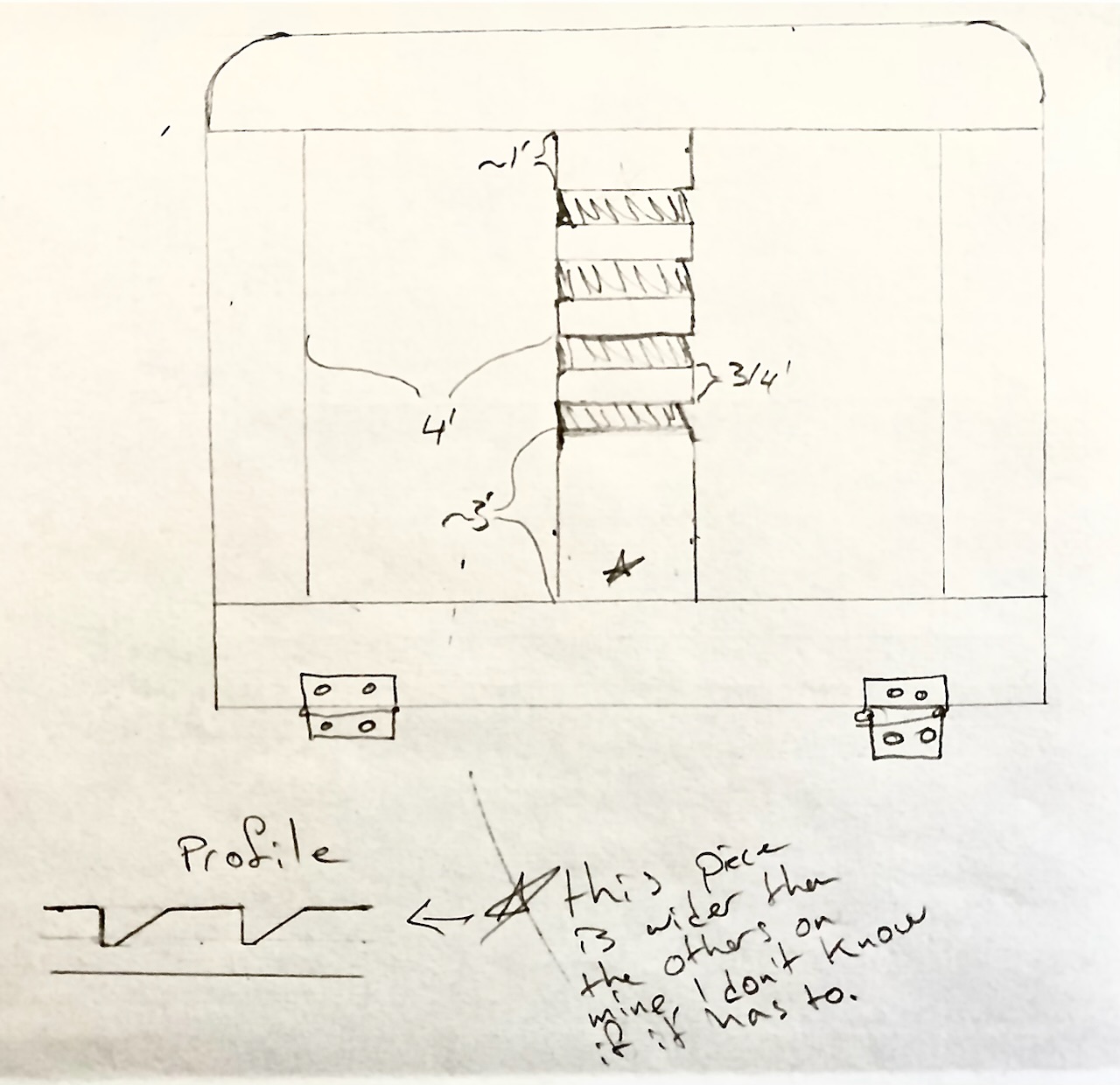

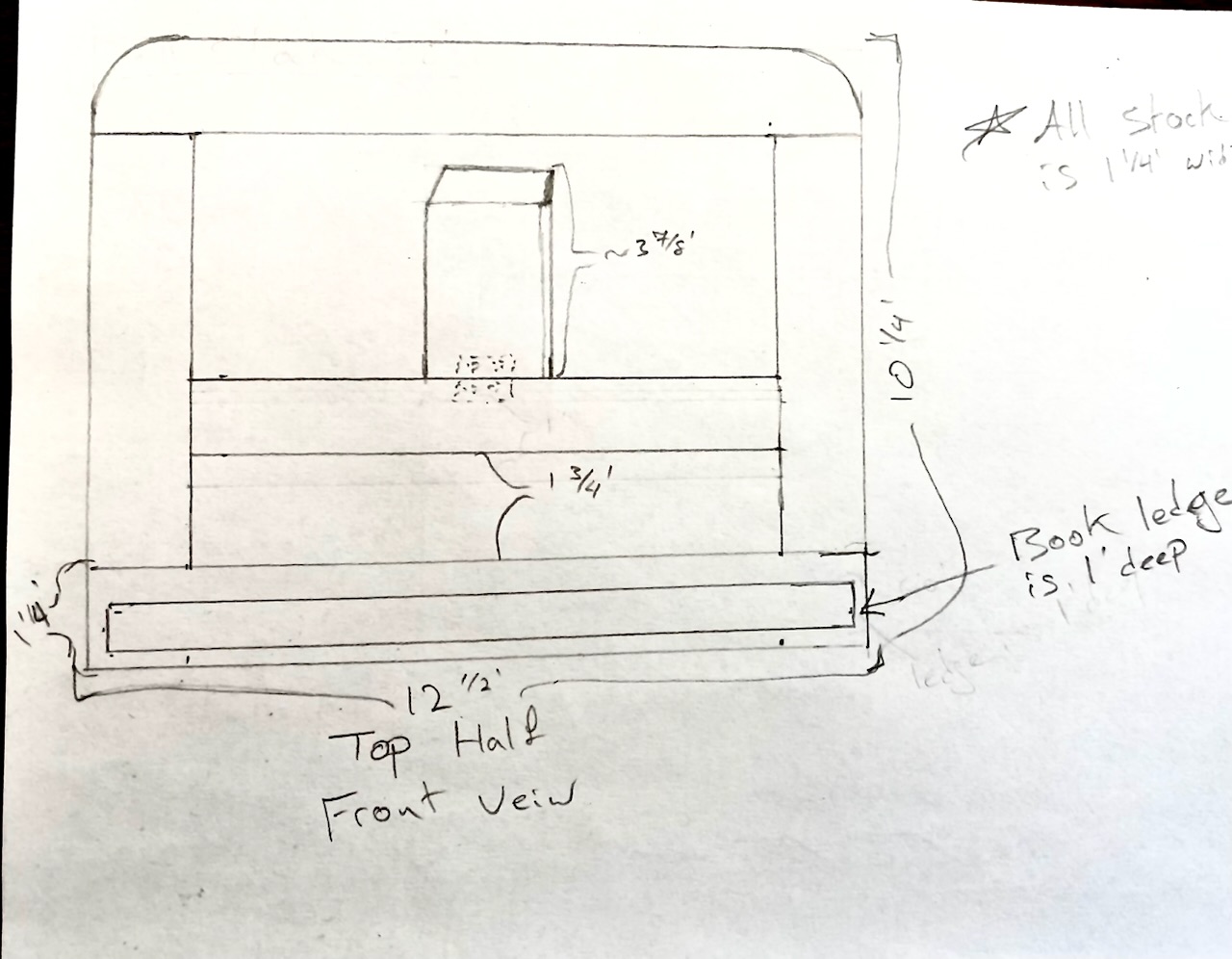

My son asked for advice on how best to make this. We discussed it a bit and both decided that I should just build and ship. He needs ten by November.

I was confused about the wood I'm using. It is actually aspen.

Aspen is a good wood for furniture that captures a rustic look. It will take stain and paint well, and it sands nicely too. While it accepts most stains well, it can be beneficial to use a sealer. Aspen is a light wood, but still offers a good degree of durability.

It is a soft hardwood, similar weight as white pine.

I was confused about the wood I'm using. It is actually aspen.

Aspen is a good wood for furniture that captures a rustic look. It will take stain and paint well, and it sands nicely too. While it accepts most stains well, it can be beneficial to use a sealer. Aspen is a light wood, but still offers a good degree of durability.

It is a soft hardwood, similar weight as white pine.

Attachments

Last edited: