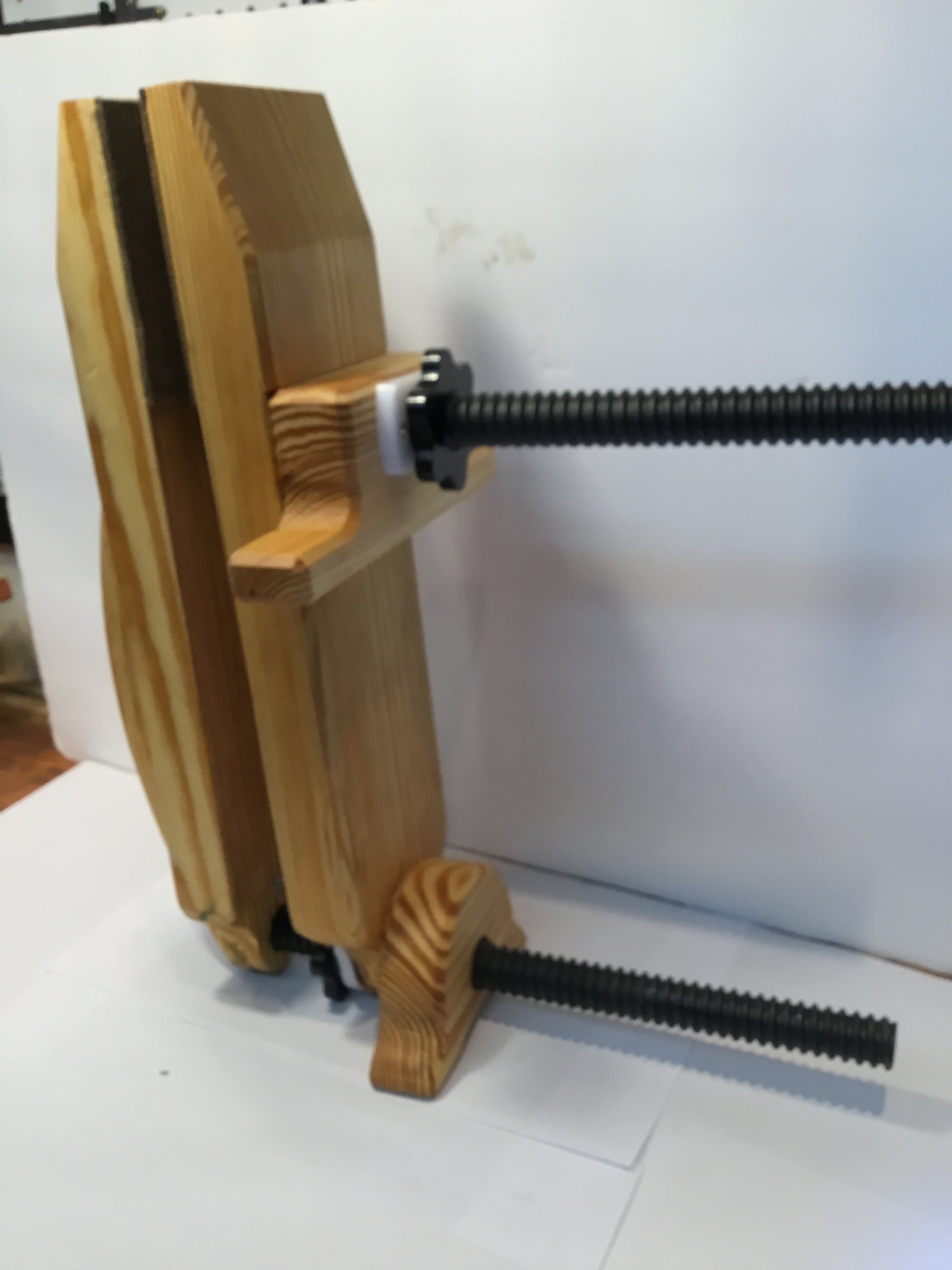

After working with the inexpensive dumbbell screws on the Moxon vise, I wondered if I could design a “get started” vise for new woodworker who didn’t have much money to spare. Here is what I came up with:

The vise is just under 18” tall and can be clamped to a workbench, a picnic table, the porch rail at your country place, etc. Since the vise’s operation in unconventional, I made a 2 1/2 minute video but get a “too large for the server to process” message when I try to upload it. Anyone know a way around this limit?

So, here goes an explanation in words rather than video:

Place your work between the chop and the fixed jaw.

Slide the chop to hold the work.

Spin the top nut to take up the slack.

Turn the bottom nut to tighten the chop.

The raw materials are:

Walmart - Two 14” dumbbell handles @ $6.87 each

Walmart - HDPE cutting board @ $9.97 (Home Goods had one for under $5)

AutoZone - Cork-rubber gasket material @ $6.99

The wood was “QSSYP”, an SYP 2x12 (from a BORG) that was center cut from the tree. Then “rip the pith out of it” to get 4-1/2” wide boards.

The net is a capable woodworking vise for $30 or so and an easy weekend build.

I have been using one for a couple of weeks now and the the unnatural action quickly becomes natural.

The vise is just under 18” tall and can be clamped to a workbench, a picnic table, the porch rail at your country place, etc. Since the vise’s operation in unconventional, I made a 2 1/2 minute video but get a “too large for the server to process” message when I try to upload it. Anyone know a way around this limit?

So, here goes an explanation in words rather than video:

Place your work between the chop and the fixed jaw.

Slide the chop to hold the work.

Spin the top nut to take up the slack.

Turn the bottom nut to tighten the chop.

The raw materials are:

Walmart - Two 14” dumbbell handles @ $6.87 each

Walmart - HDPE cutting board @ $9.97 (Home Goods had one for under $5)

AutoZone - Cork-rubber gasket material @ $6.99

The wood was “QSSYP”, an SYP 2x12 (from a BORG) that was center cut from the tree. Then “rip the pith out of it” to get 4-1/2” wide boards.

The net is a capable woodworking vise for $30 or so and an easy weekend build.

I have been using one for a couple of weeks now and the the unnatural action quickly becomes natural.