Hello friends,

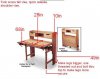

I am milling the wood for my bench right now and am going to start gluing up the top. For speeds sake I am going to go with round dog holes. I am going to need a somewhat modular bench that folds down for my next duty assignment. I found a very cool design at GarretWade, their bench was only 43.5 in X 28in. I am going to make mine 68in X 28in with no tool tray and double bench dog holes for the Veritas twin screw vise. I wanted to make the bench longer but cant in fear that it wont fit in the small space that I will be provided. Let me know what all of you seasoned WWers think and what I should look out for when building this. The top will be solid maple, and if there is enough the legs will be HM as well. If not they will be red oak. I am also looking at cabinet makers tools chest to hold all of my hand tools and such. Thanks for all of the advice and have a blessed day my friends.

Michael

I am milling the wood for my bench right now and am going to start gluing up the top. For speeds sake I am going to go with round dog holes. I am going to need a somewhat modular bench that folds down for my next duty assignment. I found a very cool design at GarretWade, their bench was only 43.5 in X 28in. I am going to make mine 68in X 28in with no tool tray and double bench dog holes for the Veritas twin screw vise. I wanted to make the bench longer but cant in fear that it wont fit in the small space that I will be provided. Let me know what all of you seasoned WWers think and what I should look out for when building this. The top will be solid maple, and if there is enough the legs will be HM as well. If not they will be red oak. I am also looking at cabinet makers tools chest to hold all of my hand tools and such. Thanks for all of the advice and have a blessed day my friends.

Michael