I recently made a wooden grooving plane which works fine save for objects with exposed joinery such as box joints. The ends of the groove sometimes show like this:

It is easy enough to make a stopped groove on a router table, but I wondered if I could solve this issue with wooden grooving planes. I have demonstrated feasibility to myself but still have a ways to go. Here are some of my thoughts before I forget. On top is my first grooving plane and the pair below it can sort of make a stopped groove.

The skate on a plane of this ilk controls the thickness of the shaving and the sole controls the groove depth. The long skate on the first plane prohibits cutting a stopped groove. The Al skates on the plane pair are around 2” long and are nestled close to the iron kind of like a chisel plane’s geometry. My first try below failed because the skate was too short and too far away and the iron would dive into the stock. Note that I moved the mouth forward about an inch for hand comfort.

Note that with laminated construction like this, it is easy to fit the ramp and breast pieces. Adding the second side completes the plane. In my case, I found that this design failed and had to retrofit the Al skates into a completed plane which is tougher.

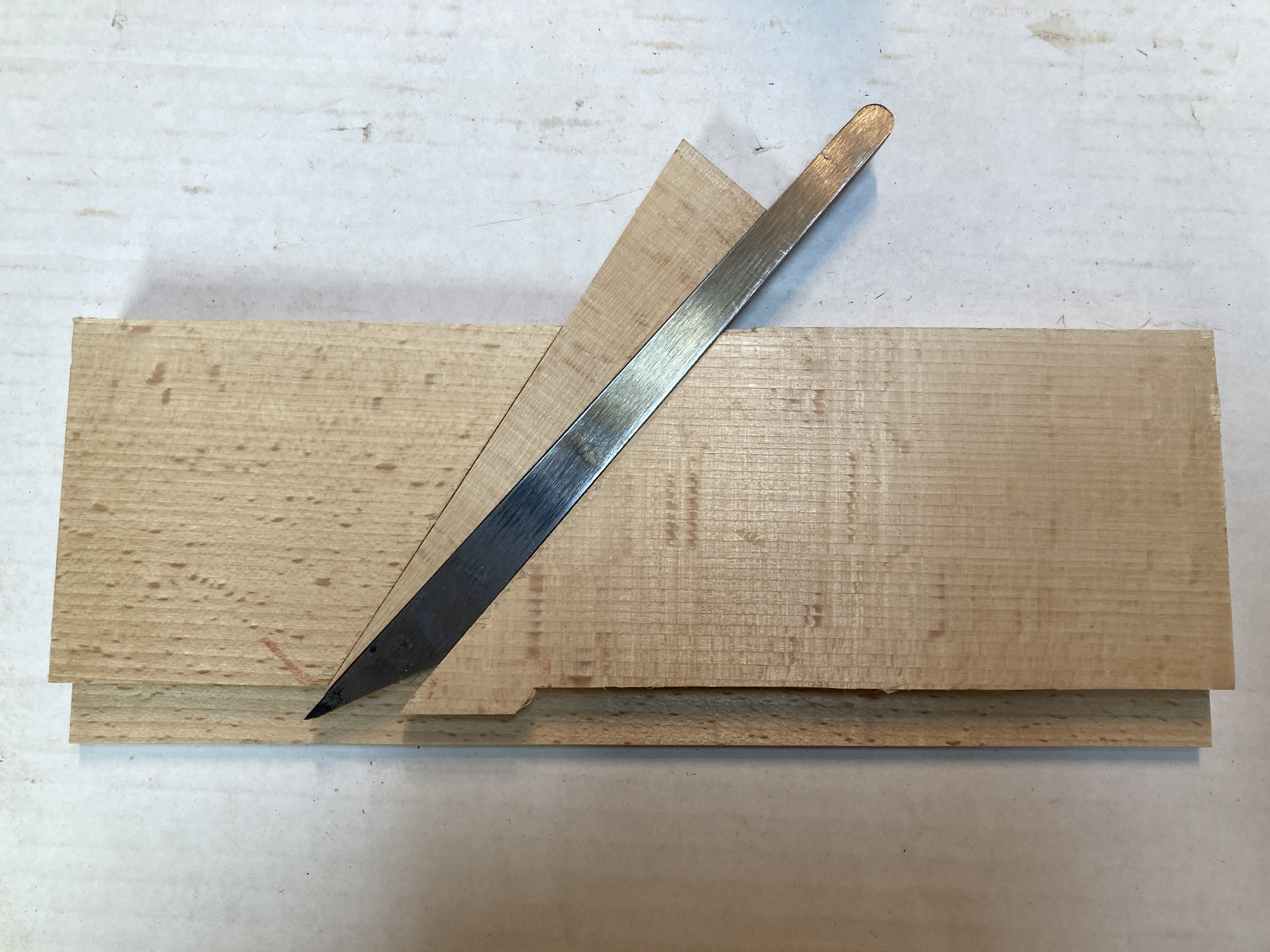

A recess to end the groove must be made. I first made a 3/16” mortise chisel from a 1/4” firmer chisel but that wanted to split out the end of the groove. Instead, I marked the hole location using the plane’s iron and drilled a blind hole to stop the groove.

Working back and forth with the two planes I was able to make a stopped groove for a drawer bottom.

I consider these having proved feasibility and now it’s time to rethink.

It is easy enough to make a stopped groove on a router table, but I wondered if I could solve this issue with wooden grooving planes. I have demonstrated feasibility to myself but still have a ways to go. Here are some of my thoughts before I forget. On top is my first grooving plane and the pair below it can sort of make a stopped groove.

The skate on a plane of this ilk controls the thickness of the shaving and the sole controls the groove depth. The long skate on the first plane prohibits cutting a stopped groove. The Al skates on the plane pair are around 2” long and are nestled close to the iron kind of like a chisel plane’s geometry. My first try below failed because the skate was too short and too far away and the iron would dive into the stock. Note that I moved the mouth forward about an inch for hand comfort.

Note that with laminated construction like this, it is easy to fit the ramp and breast pieces. Adding the second side completes the plane. In my case, I found that this design failed and had to retrofit the Al skates into a completed plane which is tougher.

A recess to end the groove must be made. I first made a 3/16” mortise chisel from a 1/4” firmer chisel but that wanted to split out the end of the groove. Instead, I marked the hole location using the plane’s iron and drilled a blind hole to stop the groove.

Working back and forth with the two planes I was able to make a stopped groove for a drawer bottom.

I consider these having proved feasibility and now it’s time to rethink.