Hi all,

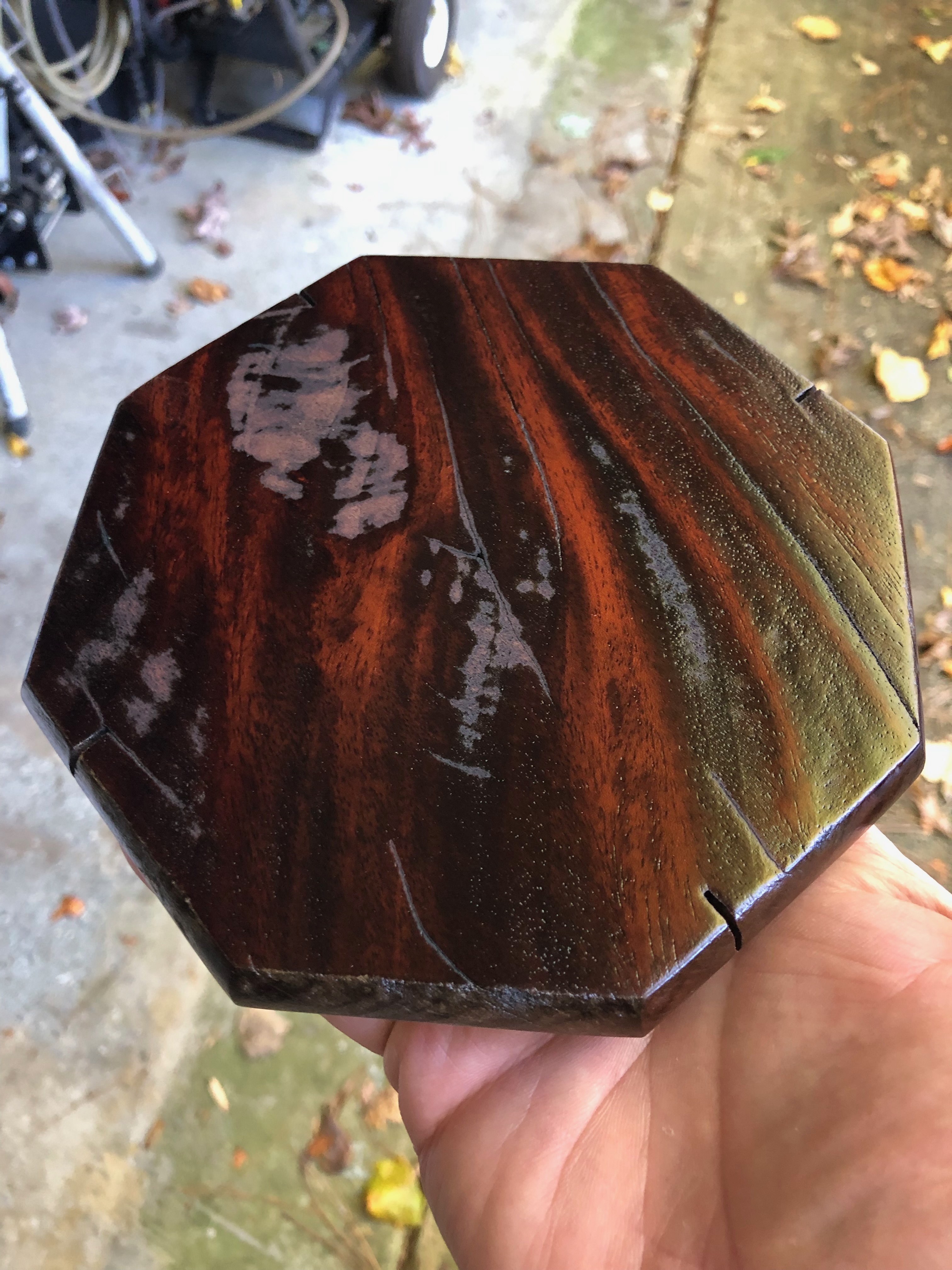

I'm attempting to restore an old set of windchimes that had sat outside for many years. The wood pieces appear to be nice pieces of walnut that I was able to progressively sand up to 240 grit before spraying with Spar Urethane. The wood was not stained and I've used this product for outside products a number of times and it's always produced a nice finish. But in this case, the product just wouldn't seem to build up on certain areas of the wood. As a result, I ended up with too much product in some places and seemingly very little in others. Is there a different method/product/etc. that I could try instead to get a consistent finish that is suitable for exposed outdoor use?

Thanks for your help!

John

I'm attempting to restore an old set of windchimes that had sat outside for many years. The wood pieces appear to be nice pieces of walnut that I was able to progressively sand up to 240 grit before spraying with Spar Urethane. The wood was not stained and I've used this product for outside products a number of times and it's always produced a nice finish. But in this case, the product just wouldn't seem to build up on certain areas of the wood. As a result, I ended up with too much product in some places and seemingly very little in others. Is there a different method/product/etc. that I could try instead to get a consistent finish that is suitable for exposed outdoor use?

Thanks for your help!

John