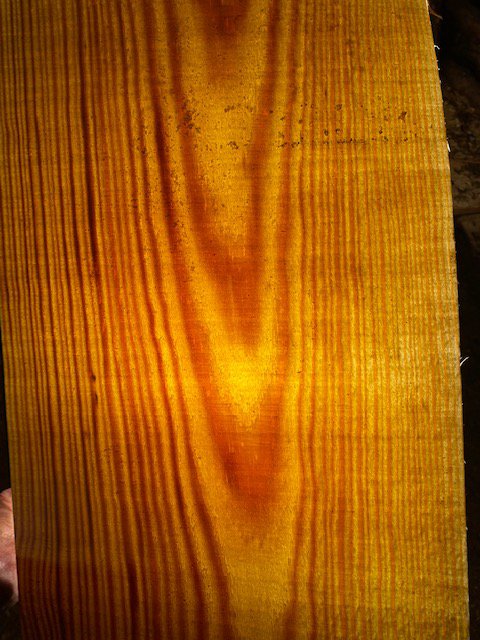

I had a pine board that I milled 1.25" thick and needed to resaw it to 1". The kerf is 0.092" so the cutoff was about 1/32" which I thought would make firepit kindling but when I illuminated it from behind (see pic) I thought this is not kindling. I am thinking now "lampshade" and advice from NCWW.

It measures 11" x 8' (I cut it shorter with scissors for easy storing and drying) and as a conical lamp shade it will require a sloped length of about 10". I assume it will survive light sanding and hope it will not crack when made into the final product. How would you make a lampshade from this? and finish it to prevent cracking? I need ideas for making/buying circular frames to which the pine will be attached to define the top and bottom of the cone.

It measures 11" x 8' (I cut it shorter with scissors for easy storing and drying) and as a conical lamp shade it will require a sloped length of about 10". I assume it will survive light sanding and hope it will not crack when made into the final product. How would you make a lampshade from this? and finish it to prevent cracking? I need ideas for making/buying circular frames to which the pine will be attached to define the top and bottom of the cone.