I got an old 26" skew back with a 3-1/2 to 4-1/2 (PPI) point rip blade with no handle from Ed Lebetkin, last year before he closed the tool store. It seems to be a very old Disston, with 5 holes, the blade has some of the etch but not enough to ID the date. The older D115 and D8 rips would have the option of ordering low PPI Less than 5 ... I was thinking this would be a good saw to rip greenwood/ crotch wood in particular, but upon inspection it doesn't have the typical tooth shape for a rip saw, it has a 20-22* rake angle, WHERE 0-8* would be normal.

First, I tried fitting a D-8 thumb hole handle (1878-1888) but it doesn't align perfectly, only the first and last holes do. I also partially restored this handle, but still need to give it a good shellacking.

I got another D-8 thumb hole handle off of Ebay thinking that might work, but they don't align as well as the first, and the saw kerf seems a bit pinched after splitting some, not sure how this might affect the saw blade. The Medallion indicates its from 1917-1940.

I just found what looks like an old Disston Wodland rip saw with a D shaped handle on Ebay, and I got to wondering if that's what my saw may have had originally. None of the info on the DIstonian Institute covers woodland saws...

I'm really just not sure what to do now, keep an eye out for an 1889-1917 era, or drill out the plate and use one of the handles I bought.

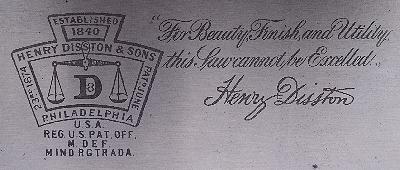

I would like it to have a thumb hole saw handle, but not sure how critical all the details are since I can't really date the saw blade... Looks closest to a very early D8, similar to this 1874 Choice saw, except I can see a faint D in the center. My saw also has the saying etched "For Beauty and Utility... like the final photo.

I really want to make the saw whole again... thoughts would be appreciated.

First, I tried fitting a D-8 thumb hole handle (1878-1888) but it doesn't align perfectly, only the first and last holes do. I also partially restored this handle, but still need to give it a good shellacking.

I got another D-8 thumb hole handle off of Ebay thinking that might work, but they don't align as well as the first, and the saw kerf seems a bit pinched after splitting some, not sure how this might affect the saw blade. The Medallion indicates its from 1917-1940.

I just found what looks like an old Disston Wodland rip saw with a D shaped handle on Ebay, and I got to wondering if that's what my saw may have had originally. None of the info on the DIstonian Institute covers woodland saws...

I'm really just not sure what to do now, keep an eye out for an 1889-1917 era, or drill out the plate and use one of the handles I bought.

I would like it to have a thumb hole saw handle, but not sure how critical all the details are since I can't really date the saw blade... Looks closest to a very early D8, similar to this 1874 Choice saw, except I can see a faint D in the center. My saw also has the saying etched "For Beauty and Utility... like the final photo.

I really want to make the saw whole again... thoughts would be appreciated.