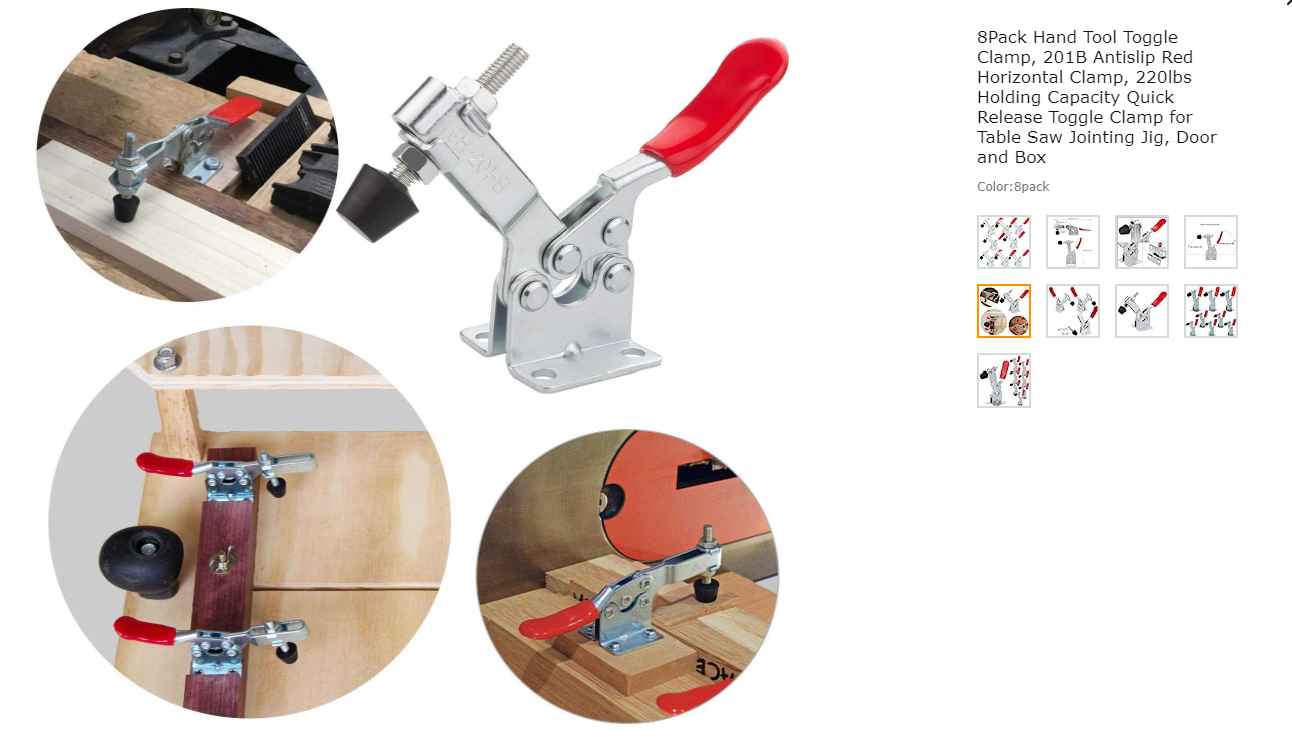

I'm starting on a gluing and clamping jig. I was thinking about using the so-called "toggle clamp" for this.

If anyone has any experience with these types of clamps, will they have enough clamping force for a proper gluing?

These will be small parts - 2, .875 x .875 x 3.0 inch pieces glued to a 1.187 x .125 inch x 10 inch piece. One at each end. So, 2 clamps attached to a board in such a way that both ends can be glued, and clamped at the same time, securely.

If anyone has any experience with these types of clamps, will they have enough clamping force for a proper gluing?

These will be small parts - 2, .875 x .875 x 3.0 inch pieces glued to a 1.187 x .125 inch x 10 inch piece. One at each end. So, 2 clamps attached to a board in such a way that both ends can be glued, and clamped at the same time, securely.