You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dust Build-up in CV1800 - Suggestions?

- Thread starter Rushton

- Start date

We heard back from Clear Vue about the problem this owner is having. Paul agrees with the comments raised here. This owner has a serious problem and its either the impeller spinning the wrong way (most likely) or the barrel having a serious leak. He acknowledges it could be a problem with the cyclone itself, but doesn't think that's likely. "Testing with a smoke test is the only way to get to the bottom of it."

For those who may be interested, Paul further commented: "Also, anything above the ramp is considered the “Dead Zone” there is no way we can get an air tight seal between the ramp and the inside cylinder tube, so there will always be a little dust that will end up on the ramp, that is why we have that hole above the ramp, it generates turbulence in the dead zone and pulls the dust back into the cyclone so it doesn’t pile up on top of the ramp which looks a little ugly, the hole also allows you to inject with an air nozzle air to keep it looking clean. It will not hurt anything having the dust up there it just looks bad, in fact all of the dust collectors out on the market if they have an internal ramp, will always have a packed dead zone full of dust its just you cannot see it."

For those who may be interested, Paul further commented: "Also, anything above the ramp is considered the “Dead Zone” there is no way we can get an air tight seal between the ramp and the inside cylinder tube, so there will always be a little dust that will end up on the ramp, that is why we have that hole above the ramp, it generates turbulence in the dead zone and pulls the dust back into the cyclone so it doesn’t pile up on top of the ramp which looks a little ugly, the hole also allows you to inject with an air nozzle air to keep it looking clean. It will not hurt anything having the dust up there it just looks bad, in fact all of the dust collectors out on the market if they have an internal ramp, will always have a packed dead zone full of dust its just you cannot see it."

Fred,

I have to agree -- I think the owner is wrong about the impeller direction because that is the only plausible reason for the significant loss of flow through the intake and down the ramp.

Edit: I am going to post a suggestion to the Owner on the ClearVue forum to suggest he remove the outlet transition and filter stack to verify that the impeller rotation is correct.

I have to agree -- I think the owner is wrong about the impeller direction because that is the only plausible reason for the significant loss of flow through the intake and down the ramp.

Edit: I am going to post a suggestion to the Owner on the ClearVue forum to suggest he remove the outlet transition and filter stack to verify that the impeller rotation is correct.

Last edited:

Text on the label is correct side up, so not likely. What I can't recall is whether it's possible to put the entire impeller housing assembly upside down--I don't think that's possible. McRabbet or James will hopefully take a look at the video to see if they spot any problem.

GEEZ! what have you been doing - sitting around drinking pina coladas? LOLmine is mostly assembled not installed. the motor, top flange, and impeller are assembled bot not on the cyclone.

Wow, I think everyone is way off base, except Paul Bushey! Please read his response and look closer at the photo.

From what I see, the top surface of the angled rectangular inlet, that comes from the left and enters the cyclone at the back and is not visible through the cylinder in this photo, aligns with the the spiral ramp at the right of the cyclone in this photo- that means the air/dust flow is below the spiral ramp as it should be, not above it!

As Paul says, what you are seeing is a dust in the dead space- there should be no flow (almost none) in that area. Dust is evidently getting into the dead space through small gaps (maybe a few large ones ) somewhere between and along the outer edges of the spiral ramp and the cylinder wall and maybe other places(?). It is not unusual, is not a problem with the blower or impeller, and should not affect cyclone performance. Try to clean or remove the dust and seal the gaps if you can, if it bothers you, but, while it doesn't look nice, it is not a major problem!

) somewhere between and along the outer edges of the spiral ramp and the cylinder wall and maybe other places(?). It is not unusual, is not a problem with the blower or impeller, and should not affect cyclone performance. Try to clean or remove the dust and seal the gaps if you can, if it bothers you, but, while it doesn't look nice, it is not a major problem!

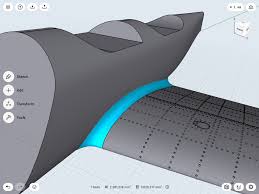

Spiral ramp design note- the spiral inlet ramp only approximates a true helix, but as I and Bill Pentz discovered, it is not a true helix because you can't make a helix from a flat sheet of material. Bill confirmed this with a math professor (at Cornell?). The best you can to is to use the helix formula to get close, then you must do some bending, warping, and fitting. Bill and I discussed this many years ago. It is evident that ClearVue does it with only partial success. Likewise it is nearly impossible to seal the edge of the ramp to the cylinder whether you build it from PETG, other plastics or metal unless you have access to the inside after installation of the ramp. When I built my Pentz-based 3D metal cyclone I made the ramp larger and bent, as best I could, the outer edge making a small, segmented flange. I adjusted the flange segments until I got a fair to decent snug fit in the cylinder. After spot soldering the ramp in place, I formed a small coved fillet with bondo between the ramp surface and cylinder wall (see photo. pink is bondo.) Note: flow is better along a curved intersection than it is along a sharp orthogonal (right angle) intersection- that is the reason airplanes have fillets between intersecting surfaces- e.g. wings to fuselage, tail to fuselage, etc., etc.

If you have access, after removing the dust, you can seal the ramp to the cyclone with various gap-filling materials.

From what I see, the top surface of the angled rectangular inlet, that comes from the left and enters the cyclone at the back and is not visible through the cylinder in this photo, aligns with the the spiral ramp at the right of the cyclone in this photo- that means the air/dust flow is below the spiral ramp as it should be, not above it!

As Paul says, what you are seeing is a dust in the dead space- there should be no flow (almost none) in that area. Dust is evidently getting into the dead space through small gaps (maybe a few large ones

Spiral ramp design note- the spiral inlet ramp only approximates a true helix, but as I and Bill Pentz discovered, it is not a true helix because you can't make a helix from a flat sheet of material. Bill confirmed this with a math professor (at Cornell?). The best you can to is to use the helix formula to get close, then you must do some bending, warping, and fitting. Bill and I discussed this many years ago. It is evident that ClearVue does it with only partial success. Likewise it is nearly impossible to seal the edge of the ramp to the cylinder whether you build it from PETG, other plastics or metal unless you have access to the inside after installation of the ramp. When I built my Pentz-based 3D metal cyclone I made the ramp larger and bent, as best I could, the outer edge making a small, segmented flange. I adjusted the flange segments until I got a fair to decent snug fit in the cylinder. After spot soldering the ramp in place, I formed a small coved fillet with bondo between the ramp surface and cylinder wall (see photo. pink is bondo.) Note: flow is better along a curved intersection than it is along a sharp orthogonal (right angle) intersection- that is the reason airplanes have fillets between intersecting surfaces- e.g. wings to fuselage, tail to fuselage, etc., etc.

If you have access, after removing the dust, you can seal the ramp to the cyclone with various gap-filling materials.

Last edited:

After reading Alan's post here and looking back at the pictures and video post on the ClearVue Cyclones forum, I posted the following there:

Well, Doh! I must admit that most of us have the wrong mindset here (me included) and have thought that the pictures you have posted show dust accumulation in the inlet chute when in fact it is accumulated in the dead air space above the chute. Thanks to Alan Schaffter (Alan in Little Washington on the NCWoodworker.net forum) for seeing the "real" picture (and I believe that's the way Paul Bushey of ClearVue Cyclones saw it as well). Your cyclone does have a larger spacing between the ramp and the central tube that extends down past the ramp from the blower intake. The dust that accumulates does not impact the cyclone's performance but it does look a bit unsightly. You might be able to dislodge much of it if you applied a jet of compressed air through the grommet while the cyclone was running.

Danka. I should have also mentioned there will likely be gaps that allow dust to get into the dead area at both the periphery of the air ramp and at the inner edge of the ramp where it meets the central tube. Since I attached the ramp to the central tube before I installed them in the cyclone cylinder, I believe I soldered the the ramp to the tube and may have applied bondo there as well.

Oh, if anyone was wondering (probably not ) about the "segmented" tabs at the edges of my air ramp that I referred to in my earlier post, the tabs pointed down so weren't visible it my photo above. You can see them in this photo of the central tube and spiral air ramp. I've included a few other photos as well.

) about the "segmented" tabs at the edges of my air ramp that I referred to in my earlier post, the tabs pointed down so weren't visible it my photo above. You can see them in this photo of the central tube and spiral air ramp. I've included a few other photos as well.

And no, I don't have a clue as to how the bondo fillet is holding up these many years later. (Borescope ?)

(Borescope ?)

Oh, if anyone was wondering (probably not

And no, I don't have a clue as to how the bondo fillet is holding up these many years later.

Last edited:

Alan, thank you for weighing in and offering a good explanation for why this is not a problem.

So, when Paul says, "Mike has a problem for sure. Like most of you guys have thought, either his impeller is going the wrong direction or he has a massive air leak. That being said it could also be our cyclone has the leak, but I put my bet on the impeller turning the wrong way, or barrel leak, Testing it with a smoke test is the only way to get to the bottom of it." Your assessment is that the leak is along the sides of the ramp INSIDE the cyclone body itself - leading into that dead air space Paul says they are never going to be able to seal completely? Am I understand you correctly?

So, when Paul says, "Mike has a problem for sure. Like most of you guys have thought, either his impeller is going the wrong direction or he has a massive air leak. That being said it could also be our cyclone has the leak, but I put my bet on the impeller turning the wrong way, or barrel leak, Testing it with a smoke test is the only way to get to the bottom of it." Your assessment is that the leak is along the sides of the ramp INSIDE the cyclone body itself - leading into that dead air space Paul says they are never going to be able to seal completely? Am I understand you correctly?

Last edited:

Yes, the "leak" is on the inside of the cyclone, likely at the joint between the top of the spiral ramp and the cylinder wall and central tube. There is a dead area area above the ramp to the bottom of the cyclone lid. Dust gets in there though vibration migration, etc. through small gaps. not because of flow. There could be flow, but that would require gaps at the ramp and a gap (leak) in the cyclone top which is also possible, I guess. It is like the old beater of a car I had in Bahrain years ago before Desert Storm. The dust was so fine in the Middle East, it would get into anything and everything not hermetically sealed, e.g. dome lights, instrument panel, etc.

The best way to remove the dust and seal what needs to be sealed is to remove the motor/blower and top of the cyclone. Otherwise you would likely need to drill an access hole, vacuum out the dust and patch the access hole. Since you can't unbolt the cone on a ClearVue, correct?, to seal gaps, you need to again remove everthing up top or you may be able to reach in through the inclined inlet. You need to seal the joints between the spiral ramp and the cylinder wall and central tube all the way around using thick-bodied PETG plastic solvent glue or silicone.

To do a good smoke check- put the cyclone under pressure and light up a stogey.Remove the filter and block off the fan outlet and block off the inlet. Connect the blow side of a vac or fan to the the cone dust outlet. Then drill a little hole into the void. Blow smokey into the cone and see where it is entering the dead space. Or even better do it in reverse- blow smoke into a hole in the dead space and add a little pressurize to see where the smoke goes inside the cyclone.

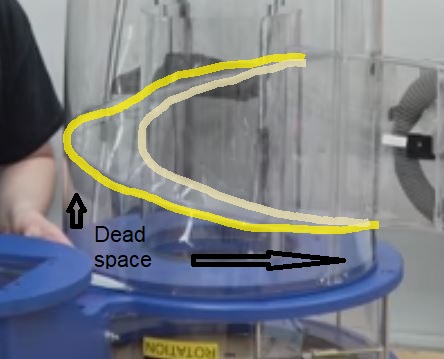

I tried to find a good view to show the dead space and where you need to seal, but could find a decent one on the web. The dead space is the space between the top of the spiral ramp and underside to the cone top. Anyway, you need to check for gaps and seal the joint between the spiral ramp and the cylinder (yellow) and the joint between the ramp and the central tube (tan).

The best way to remove the dust and seal what needs to be sealed is to remove the motor/blower and top of the cyclone. Otherwise you would likely need to drill an access hole, vacuum out the dust and patch the access hole. Since you can't unbolt the cone on a ClearVue, correct?, to seal gaps, you need to again remove everthing up top or you may be able to reach in through the inclined inlet. You need to seal the joints between the spiral ramp and the cylinder wall and central tube all the way around using thick-bodied PETG plastic solvent glue or silicone.

To do a good smoke check- put the cyclone under pressure and light up a stogey.

I tried to find a good view to show the dead space and where you need to seal, but could find a decent one on the web. The dead space is the space between the top of the spiral ramp and underside to the cone top. Anyway, you need to check for gaps and seal the joint between the spiral ramp and the cylinder (yellow) and the joint between the ramp and the central tube (tan).

Last edited:

Come and see. Wear work clothes.GEEZ! what have you been doing - sitting around drinking pina coladas? LOL

I noticed that the gap between the central tube and the ramp on the original poster's CV-1800 (Post #17 on the ClearVue Forum) was larger than I have seen in most cases. It is clearly visible in the stopped 3-second video he posted. As discussed above, the dust could be removed by dismantling the cone section from the blower and then removing the solid MDF top plug that centers the tube (in my 13 year old model, it is held in place with several screws). The "dead area will be exposed and could be cleaned out. If he went to the trouble to do that, he might be able to add a piece of clear Tygon tubing slit along its length and inserted over the ramp edge, thus narrowing the gap when the tube is re-inserted. The easier approach as I suggested above would be to use compressed air through the grommet seen in his video to re-suspend the dust accumulation and get it to exit back through the gap. It might be feasible to seal the gap with silicone sealant by hand through the inlet chute, but it would be difficult.

LATEST FOR SALE LISTINGS

-

-

-

SOLD -- $75: Gast moa v113 Vacuum Pump Veneer, 60" bag and board

- Started by peterdnight

- Replies: 1

-

GONE: Gladiator 5 cleats, 10 hangers, Paper Towel and Shelf

- Started by peterdnight

- Replies: 3

-

SOLD -- $100 Makita mac700 portable air + grex pin nailer + 2 others + 50' hose

- Started by peterdnight

- Replies: 1