I recently purchased a new air compressor. The old one just kind of faded away, the motor seamed to just lose power and run slow and then finally wouldn't start. The new one worked great till i plugged it into to the same outlet and then it wouldn't run at the right speed. I moved it to an outlet across the shop and it ran just like it should. I think the outlet might be the problem but how do i trouble shoot it? Could it be the breaker? the wires? a bad outlet between the one i use and the breaker? At least i got a new compressor :tool:that i didn't need. Now what to do with the old one?:BangHead:

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Shop electrical problems?

- Thread starter bluchz

- Start date

-

- Tags

- electrical problems shop

- Status

- Not open for further replies.

Am not electrician but: If you have a vom and have worked with electricity before; Here is what I would do if it was my problem;

First measure the voltage thru the outlet; turn power off, pull outlet out of box and do a good visual on the connections; then power up and measure at the Wires where they enter the recept, if there is any kind of diff power off and replace the recept. OR

Just turn power off and change the bloody receptacle, power on with this caveat, if you choose to just change and u SEE a problem then fix that ,then change recept anyway :}

First measure the voltage thru the outlet; turn power off, pull outlet out of box and do a good visual on the connections; then power up and measure at the Wires where they enter the recept, if there is any kind of diff power off and replace the recept. OR

Just turn power off and change the bloody receptacle, power on with this caveat, if you choose to just change and u SEE a problem then fix that ,then change recept anyway :}

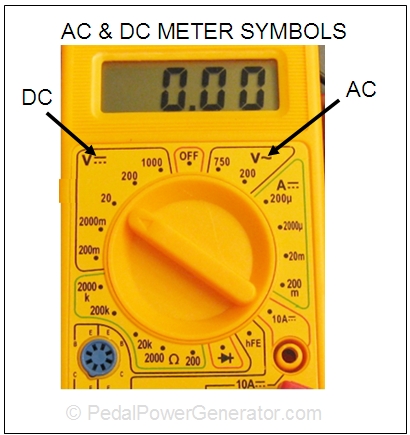

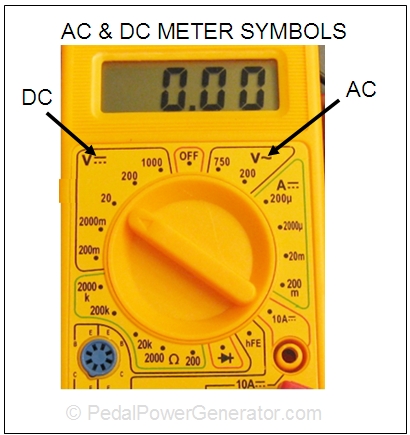

What Jack said. You can get a decent volt meter at Harbor Freight for $5. Set it to measure alternating current, if you're not sure how to do that see this tutorial.

Stick the two prongs on the multimeter in the outlet, just like you would insert a regular plug. The volt meter should read roughly 120V.

Most likely, there's a loose wire in the receptacle. That will require a visual inspection, but if you wiggle the multimeter prongs a little and you see the reading fluctuate, that's a good indicator too. Be safe. Like Jack said, turn off the breaker before opening it up. Use the volt meter to verify the outlet is indeed turned off. The label in the panel isn't always correct.

If all the connections check out, the outlet could be bad. Replacing one is pretty straightforward. If that doesn't solve it, it's also possible that there is something wrong upstream of the outlet. It's not uncommon for one outlet to feed the next, so a loose connection in one area can cause problems downstream. With the breaker off, you can determine which outlets are dead, and therefore on the same circuit. I'd check each one.

As for the other air compressor: Lots of options here. You can sell it here on NCWW or on Craig's List. You can give it to a friend. You can keep it as a spare in the garage, and use it to service the cars. If the issue of having a second air compressor is giving you sleepless nights, I'd reluctantly accept it as a gift - but only to make you feel better of course

Stick the two prongs on the multimeter in the outlet, just like you would insert a regular plug. The volt meter should read roughly 120V.

Most likely, there's a loose wire in the receptacle. That will require a visual inspection, but if you wiggle the multimeter prongs a little and you see the reading fluctuate, that's a good indicator too. Be safe. Like Jack said, turn off the breaker before opening it up. Use the volt meter to verify the outlet is indeed turned off. The label in the panel isn't always correct.

If all the connections check out, the outlet could be bad. Replacing one is pretty straightforward. If that doesn't solve it, it's also possible that there is something wrong upstream of the outlet. It's not uncommon for one outlet to feed the next, so a loose connection in one area can cause problems downstream. With the breaker off, you can determine which outlets are dead, and therefore on the same circuit. I'd check each one.

As for the other air compressor: Lots of options here. You can sell it here on NCWW or on Craig's List. You can give it to a friend. You can keep it as a spare in the garage, and use it to service the cars. If the issue of having a second air compressor is giving you sleepless nights, I'd reluctantly accept it as a gift - but only to make you feel better of course

Step 1 - check the voltage at the receptacle as recommended by Sky and Bas.

Step 1 - flip the circuit breaker off, and then back on. Check the voltage again.

Odds are that the breaker may have caused the problem.

If not, you most likely have a problem either in the breaker, in the connection from the breaker to the wires, or the connection from the wires to the receptacle. Look for signs of hot insulation on the wires (discolored) near the breaker and receptacle - if a connection is loose it will cause the wire to overheat.

Turn the breaker off, tighten up the screws holding the wires in place at the breaker and at the receptacle, then turn the breaker back on and re-measure with the meter.

Step 1 - flip the circuit breaker off, and then back on. Check the voltage again.

Odds are that the breaker may have caused the problem.

If not, you most likely have a problem either in the breaker, in the connection from the breaker to the wires, or the connection from the wires to the receptacle. Look for signs of hot insulation on the wires (discolored) near the breaker and receptacle - if a connection is loose it will cause the wire to overheat.

Turn the breaker off, tighten up the screws holding the wires in place at the breaker and at the receptacle, then turn the breaker back on and re-measure with the meter.

There is one point in Bas's instructions I would like to clarify for beginners. While "Alternating Current" is technically (and 100%) correct, the reference to "current" could lead a beginner to assume they are measuring current, thereby setting their meters (photo aside) to Current (Amps) mode which, depending upon the particular meter can result in: 1) nothing much because current testing requires moving the positive test lead to another socket, 2) an anti-climatic finish that leaves the meter temporarily unusable (as in always reading 0.00 or over-range) due to a blown fuse, or 3) in [mostly] cheap meters it may result in a spectacular and catastrophic failure as the entire meter instantaneously goes up in smoke and flames. I feel it is safer to instruct beginners to set their meters to "AC Volts" for autoranging meters and a range of at least 200VAC for manual ranging meters (for 120V outlets, select a range of 400+VAC for 240V outlets).

Although some corrective action is almost certainly necessary for this issue, I feel the provided instructions are incomplete. While we are certainly interested in the initial unloaded voltage on this problem receptacle, the number that really matters is the voltage under maximum load -- in other words, the voltage drop. For a 120V receptacle we generally want to see between 110V and 125V on an unloaded receptacle. If you measure voltage signicantly more or less than this then it warrants further investigation elsewhere in your house to determine if the over- or under-voltage condition is endemic or specific to that receptacle. If the issue is endemic (as in all -- or atleast 1/2 -- your receptacles) then you need to contact your local power provider to resolve the issue, which will likely involve replacing your electrical drop's transformer.

If you have established that your home's voltage is within the expected range of 110-125V (for a 120V receptacle) then we can proceed with the knowledge that this issue is isolated to a single circuit (a circuit may consist of anywhere from a single outlet to a series of outlets and/or lights or other household accessories all of which reside on a single circuit breaker).

Once you have determined the unloaded voltage on the problem receptacle, go ahead and connect your compressor (use no extension cords) and power it on WHILE STILL MONITORING voltage. If you see a voltage drop of more than about 5-7% (5-8VAC) less than the unloaded voltage OR if either of these voltages appears to be intermittently dropping out (as in loose connection) then you have a definite problem with this circuit (either at this receptacle, the circuit breaker/fuse, or somewhere in between). You should register the maximum voltage drop as the compressor approaches peak [amp] load just before it's high-pressure cutoff. If you saw wild fluctuations in voltage then you likely have a loose connection at the receptacle, circuit breaker/fuse or anywhere in between. However, if you have excessive, but essentially steady, voltage drop then you have excessive resistance within the circuit which may be as simple as a loose connection or as complicated as an illegal tap (if your home has ever been remodelled -- psuedo-professionally or DIY), undersized wiring or even knob-and-tube (if an older home) wiring.

Go ahead and TURN OFF THE CIRCUIT BREAKER/FUSE for this receptacle, open the outlet box and try tightening down all the receptacle's screws and make certain that the all the wires make firm contact with their respective screws. If this outlet makes loose contact with the plug (i.e. you can easily pull a cord out of the receptacle with little effort) then the internal contacts may have lost their spring pressure in which case this is the perfect time to replace the receptacle since loose contact can cause the same symptoms and lead to an overheated outlet and plug. If you replace the receptacle, the white wire goes to the nickel screw (on same side as the wide receptacle prong) the black or red wire goes to the brass screw (short prong side) and the bare or green wire to the green ground screw. Afterward, go ahead and close up the receptacle outlet and flip the circuit breaker/fuse back on. Retest to see if this solved your problem.

If the above did not solve your problem then I really -- and strongly -- recommend you SECURE THE SERVICES OF A QUALIFIED ELECTRICIAN to troubleshoot and solve the problem for you. Loose and/or high-resistance connections are not something you want to ignore because they lead to overheated wiring and junctions when under load WHICH CAN RESULT IN FIRE! Residential wiring often serves multiple receptacles, lights, switches, smoke detectors and other household accessory loads which can make tracing the connection back to the circuit breaker/fuse panel challenging -- especially in homes with hidden junction boxes, illegal taps or knob-and-tube wiring -- and outside the realm of what the average homeowner is equipped to deal with.

Although some corrective action is almost certainly necessary for this issue, I feel the provided instructions are incomplete. While we are certainly interested in the initial unloaded voltage on this problem receptacle, the number that really matters is the voltage under maximum load -- in other words, the voltage drop. For a 120V receptacle we generally want to see between 110V and 125V on an unloaded receptacle. If you measure voltage signicantly more or less than this then it warrants further investigation elsewhere in your house to determine if the over- or under-voltage condition is endemic or specific to that receptacle. If the issue is endemic (as in all -- or atleast 1/2 -- your receptacles) then you need to contact your local power provider to resolve the issue, which will likely involve replacing your electrical drop's transformer.

If you have established that your home's voltage is within the expected range of 110-125V (for a 120V receptacle) then we can proceed with the knowledge that this issue is isolated to a single circuit (a circuit may consist of anywhere from a single outlet to a series of outlets and/or lights or other household accessories all of which reside on a single circuit breaker).

Once you have determined the unloaded voltage on the problem receptacle, go ahead and connect your compressor (use no extension cords) and power it on WHILE STILL MONITORING voltage. If you see a voltage drop of more than about 5-7% (5-8VAC) less than the unloaded voltage OR if either of these voltages appears to be intermittently dropping out (as in loose connection) then you have a definite problem with this circuit (either at this receptacle, the circuit breaker/fuse, or somewhere in between). You should register the maximum voltage drop as the compressor approaches peak [amp] load just before it's high-pressure cutoff. If you saw wild fluctuations in voltage then you likely have a loose connection at the receptacle, circuit breaker/fuse or anywhere in between. However, if you have excessive, but essentially steady, voltage drop then you have excessive resistance within the circuit which may be as simple as a loose connection or as complicated as an illegal tap (if your home has ever been remodelled -- psuedo-professionally or DIY), undersized wiring or even knob-and-tube (if an older home) wiring.

Go ahead and TURN OFF THE CIRCUIT BREAKER/FUSE for this receptacle, open the outlet box and try tightening down all the receptacle's screws and make certain that the all the wires make firm contact with their respective screws. If this outlet makes loose contact with the plug (i.e. you can easily pull a cord out of the receptacle with little effort) then the internal contacts may have lost their spring pressure in which case this is the perfect time to replace the receptacle since loose contact can cause the same symptoms and lead to an overheated outlet and plug. If you replace the receptacle, the white wire goes to the nickel screw (on same side as the wide receptacle prong) the black or red wire goes to the brass screw (short prong side) and the bare or green wire to the green ground screw. Afterward, go ahead and close up the receptacle outlet and flip the circuit breaker/fuse back on. Retest to see if this solved your problem.

If the above did not solve your problem then I really -- and strongly -- recommend you SECURE THE SERVICES OF A QUALIFIED ELECTRICIAN to troubleshoot and solve the problem for you. Loose and/or high-resistance connections are not something you want to ignore because they lead to overheated wiring and junctions when under load WHICH CAN RESULT IN FIRE! Residential wiring often serves multiple receptacles, lights, switches, smoke detectors and other household accessory loads which can make tracing the connection back to the circuit breaker/fuse panel challenging -- especially in homes with hidden junction boxes, illegal taps or knob-and-tube wiring -- and outside the realm of what the average homeowner is equipped to deal with.

If you wind up needing an electrician and don't know one you trust, PM me.

If it's a 110 recpt, less than $5 will buy you a good 20 amp duplex recpt. Don't even mess with those $0.59 ones on the bottom shelf at the borgs. Check to see if existing recpt has "push in wiring." This means wires are striped, and simply pushed into back side of the recpt. Only a tiny little spring makes the contact between recpt. and wire. The female parts of recpts go bad over time. They loose their ability to grip plug prongs.

My input is not different from the other posts, to me, but will be stated a different way. I would start with a voltage measurement and would not be surprised if it read fine but dropped a lot when a load was applied. It doesn't need to be the compressor, a drill is probably enough to drop the voltage if there is a problem. I mention a drill becuase it uses a universal motor. I believe they are less sensitive to voltage (and thus more likely to run if there is a problem). Virtually all hand-held tools are universal motors so you could use a router or other tool to check this.

If it is a voltage issue then you start with that outlet and move back along the circuit (if you know which way it goes). I don't think outlets "go bad" in a way that reduces voltage. So I would be looking for a loose connection. But outlets are cheap so if you can't find a connection issue but the voltage is good up to a point and then unacceptable, replace the outlet.

My other input is relative to the compressor. I used to use a home made table saw with a 1 hp induction motor. I had to clean out the stator a few times because it filled with sawdust. There are air gaps in the stator (stationary part of the motor) that can't be filled with sawdust or the motor will run poorly and then won't start. The solution is just to blow out the sawdust. I don't know that there is any issue with your old compressor but the way you describe it sounds like the problems I used to have with my table saw.

Jim

If it is a voltage issue then you start with that outlet and move back along the circuit (if you know which way it goes). I don't think outlets "go bad" in a way that reduces voltage. So I would be looking for a loose connection. But outlets are cheap so if you can't find a connection issue but the voltage is good up to a point and then unacceptable, replace the outlet.

My other input is relative to the compressor. I used to use a home made table saw with a 1 hp induction motor. I had to clean out the stator a few times because it filled with sawdust. There are air gaps in the stator (stationary part of the motor) that can't be filled with sawdust or the motor will run poorly and then won't start. The solution is just to blow out the sawdust. I don't know that there is any issue with your old compressor but the way you describe it sounds like the problems I used to have with my table saw.

Jim

- Status

- Not open for further replies.

Similar threads

- Replies

- 24

- Views

- 1K