You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

shaping

-

S

trim shaping problem

I am trying to figure out how to match some trim for a piece I'm working on. I need 25' of OAK 3/4 X 1 1/2 with a 3/4" bull nose type curve on each side. I could just use a bull nose router bit, but it would leave a flat spot between curves. I could also cut a bull nose on each piece, rip it to...- skeeter

- Thread

- problem shaping trim

- Replies: 9

- Forum: General Woodworking

-

Stock shaping tools

I need to purchase a few tools to take a gunstock blank, like the one below, and shape into an American Longrifle stock. The barrel channel will be roughed in, and the ramrod hole drilled, by the stock seller, but thats all. I'm looking for opinions/suggestions on which tools to buy for...- Tom Dunn

- Thread

- shaping stock tools

- Replies: 7

- Forum: Hand Tools and their Use

-

Shaping pine or time travel, which is more likely?

Ok, I am considering joining the IHSYP International. (I Hate Southern Yellow Pine). The HOW (Hillsborough Orange Woodworkers Meetup) is furiously working on the Popular Woodworking Skansen Bench. We have big inside and outside radius curves in the legs that needed shaping. We sawed...- froglips

- Thread

- pine shaping time travel

- Replies: 16

- Forum: Hand Tools and their Use

-

Intarsia 101 more shaping and carving

On the last segment I went over the basics of tracing, cutting and sanding so now I will go into some of the details of carving and contouring that make intarsia unique. After a piece has been traced,[including carving lines as per pattern] and sawn out, now is the time to carve in the details...- wdkits1

- Thread

- 101 carving intarsia shaping

- Replies: 7

- Forum: "How To" Forum

-

Intarsia 101 Tracing,cutting, shaping

I managed to get a few pieces done today so I'll begin by showing the steps needed to begin the intarsia process. This photo shows the set-up to trace a section from the pattern onto sticky back label paper. I have taped the pattern down and have slid the carbon paper and label paper under the...- wdkits1

- Thread

- 101 cutting intarsia shaping tracing

- Replies: 19

- Forum: "How To" Forum

-

M

Shaping on a router table?

Howdy folks -- I've got some shaping to do with those mini sanding drums. I don't have a drill press and I SURE don't have a proper shaper. So...here's my question. Is it okay to use sanding drums on a router table? The shafts are 1/4" and 1/2", so they fit snug in my collets. But my...- maomoonshiner

- Thread

- router shaping table

- Replies: 10

- Forum: Power Tools and Their Use

-

The after class shaping part 2 1/2 -the front legs

Worked on the front legs of the rocker today, and I must say this has been the hardest process yet. The starting point was on the right and off the grinder form is on the left: Once off the grinder had to use a #8 carving chisel to "bring out the round half" of the leg-the part that's not in...- Shamrock

- Thread

- 1 or 2 class front legs part shaping

- Replies: 4

- Forum: General Woodworking

-

Maloof Rocker-After Class shaping Part 2-The back legs

Well here's what the chair looked like after shaping the rockers: The 1st task was to mark what areas to avoid in shaping and to take the chair apart (this is like the 100th or so time it's come apart):tinysmile_tongue_t: Here's what the before leg looks like: Then I marked the bottom around...- Shamrock

- Thread

- 2the back class legs maloof part rockerafter shaping

- Replies: 3

- Forum: General Woodworking

-

Maloof Rocker-The after class shaping Part 1

Hey Folks- Let me just second what Jeremy said about John's (Woodguy1975) rocker class-phenomenal! Of the 3 students, none of us had ever built a chair before and we all left with working rocking chairs! Having said that, a good part of the chairs' character comes from the shaping, and that's up...- Shamrock

- Thread

- class maloof part rockerthe shaping

- Replies: 9

- Forum: General Woodworking

-

Router-table sub-plate aids small part shaping

When shaping small parts on the router table, the large center hole in the router-table mounting plate is problematic. To get around this, I drilled a small bit-clearance hole in a scrap piece (here I used 1/4" MDF) and temporarily affixed this "sub-plate" to the table with double-stick tape...- johnpipe108

- Thread

- aids part routertable shaping small subplate

- Replies: 2

- Forum: "How To" Forum

-

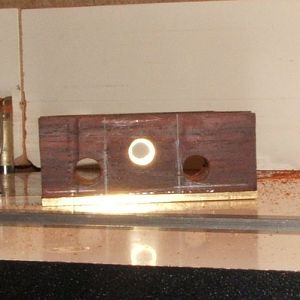

Sight-base blank prepped for profiling

This rosewood blank has been drilled through the waste area and the slot has been cut; saw cuts will be made tangent to the holes to remove the waste before profiling on the router table. The pivot bushings have been installed- johnpipe108

- Media item

- preparation routing shaping

- Comments: 0

- Album: A Rosewood Rifle Sight