I am thinking of making a few little carving knives for fun or gifts. I don't actually do much carving so I am wondering if someone can help give me a little direction.

I'm looking to do something in this genre to start:

www.woodcraft.com

www.woodcraft.com

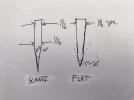

I have some 1/16" O1 stock and thinking of aiming for a scandi grind (one primary bevel, no secondary bevel, part of the blade remains flat above the bevel) with about a 15 degree included bevel angle for softer woods like basswood, maybe will make one with a higher angle for utility use in hardwoods.

Does that sounds reasonable or would you do something else if you were making this sort of carving knife?

I'm looking to do something in this genre to start:

pfeil Swiss made #1 Knife Chip Carving | Woodcraft

Buy the #1 Knife Chip Carving for sale online from Woodcraft. Visit us to order online or find your local Woodcraft store today!

I have some 1/16" O1 stock and thinking of aiming for a scandi grind (one primary bevel, no secondary bevel, part of the blade remains flat above the bevel) with about a 15 degree included bevel angle for softer woods like basswood, maybe will make one with a higher angle for utility use in hardwoods.

Does that sounds reasonable or would you do something else if you were making this sort of carving knife?