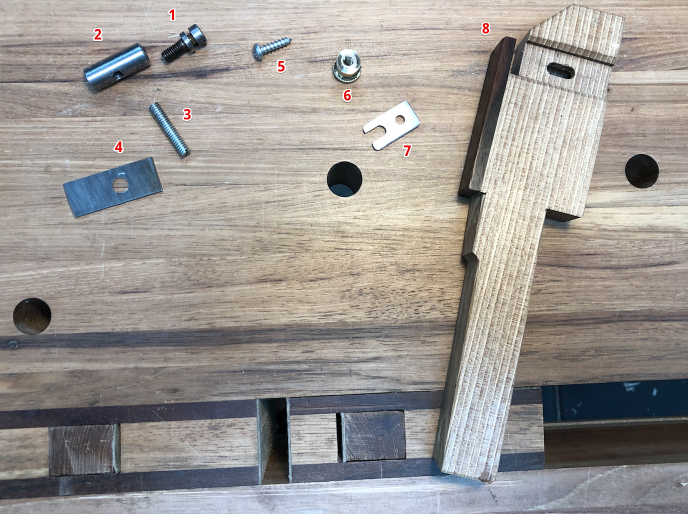

Watching a video of Steve Latta using his homemade gauge to size stringing for inlay inspired me to make my own version with a couple of twists. It combines some metal work and wood work. Here's a picture of all the parts with descriptions below.

The next picture shows it fully assembled except for the blade. Turning the adjustment screw causes the threaded rod to move in or out, giving you fine control over the gap before locking the blade in place.

This picture shows it fully assembled and ready to use. Tightening the knurled brass nut locks the blade in place. Loosen and turn the adjustment screw to size the gap.

To use the gauge you first slice a piece of veneer, the pull it through the gap to size it to a uniform thickness. Note the blade has a slight angle towards the top of the gap. This is necessary to start the gauging process. Otherwise, the string would be too wide to fit into the gap.

The next shot shows the gauge in use. You can see the fine shavings coming off as it's pulled through the gap.

Finally, this is what I meant by having it insert into a dog hole on the bench. The bench dog is laying beside the gauge. This makes it really convenient to use at any number of spots along the bench without having to tie up one of my vises.

Fun Saturday project!

- Frog adjusting screw from Stanley #5.

- 1/2" x 1-1/4" barrel bolt with end threaded to accept the adjusting screw. I used some scrap 1/2" drill rod.

- 1/4" threaded rod for lock nut (number 6)

- Gauging blade (made from used Dewalt 735 planer blade)

- Screw for adjusting screw lock

- Lock nut for holding blade in place

- Adjusting screw lock

- Gauge body (ebony & hickory)

The next picture shows it fully assembled except for the blade. Turning the adjustment screw causes the threaded rod to move in or out, giving you fine control over the gap before locking the blade in place.

This picture shows it fully assembled and ready to use. Tightening the knurled brass nut locks the blade in place. Loosen and turn the adjustment screw to size the gap.

To use the gauge you first slice a piece of veneer, the pull it through the gap to size it to a uniform thickness. Note the blade has a slight angle towards the top of the gap. This is necessary to start the gauging process. Otherwise, the string would be too wide to fit into the gap.

The next shot shows the gauge in use. You can see the fine shavings coming off as it's pulled through the gap.

Finally, this is what I meant by having it insert into a dog hole on the bench. The bench dog is laying beside the gauge. This makes it really convenient to use at any number of spots along the bench without having to tie up one of my vises.

Fun Saturday project!